Submerged Surface Cleaner

a technology of cleaners and submerged surfaces, applied in the field of submerged surface cleaners, can solve the problems of adding unnecessarily to the complexity and cost of cleaning cleaners, and achieve the effect of improving the cleaning effect and improving the cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

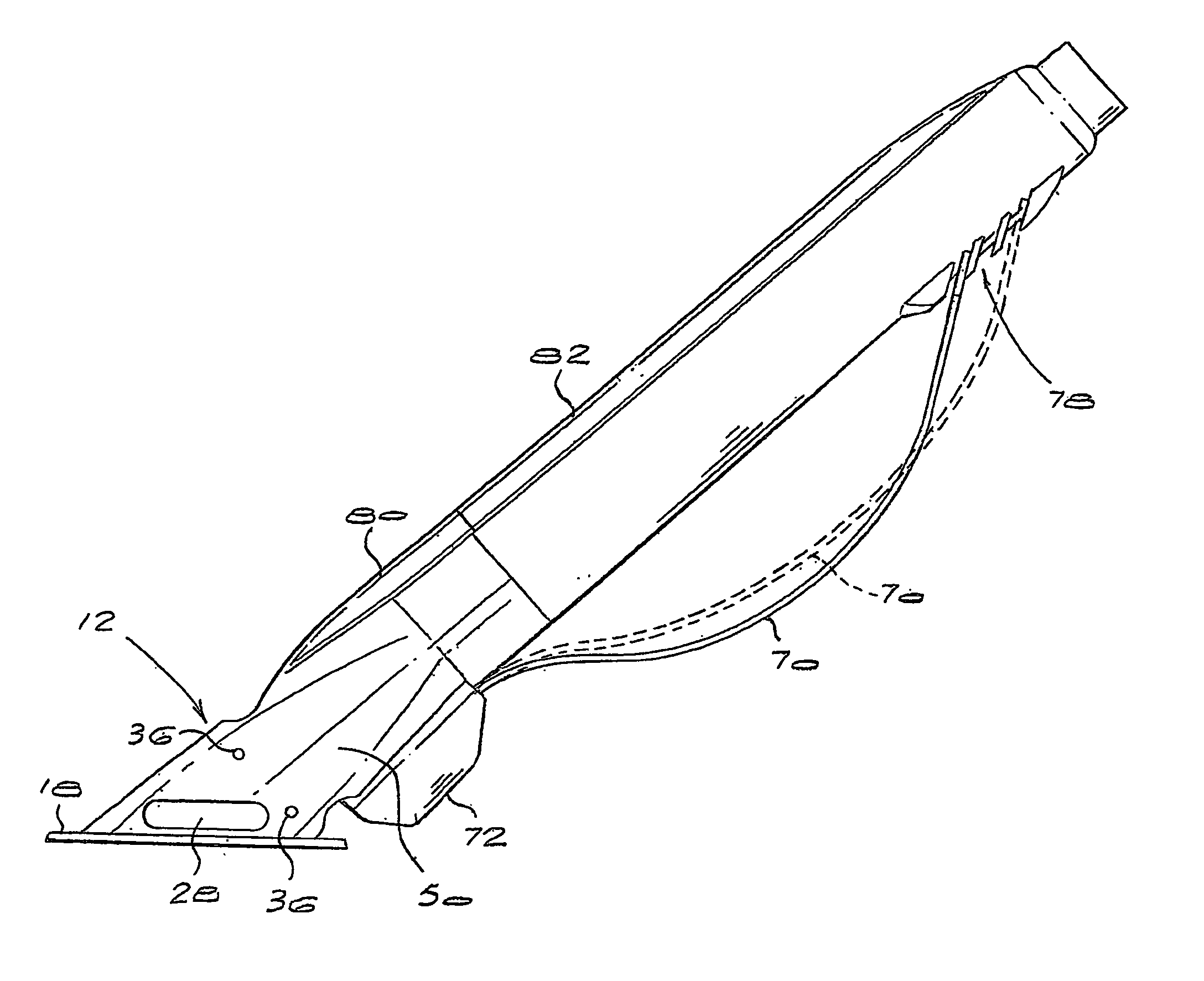

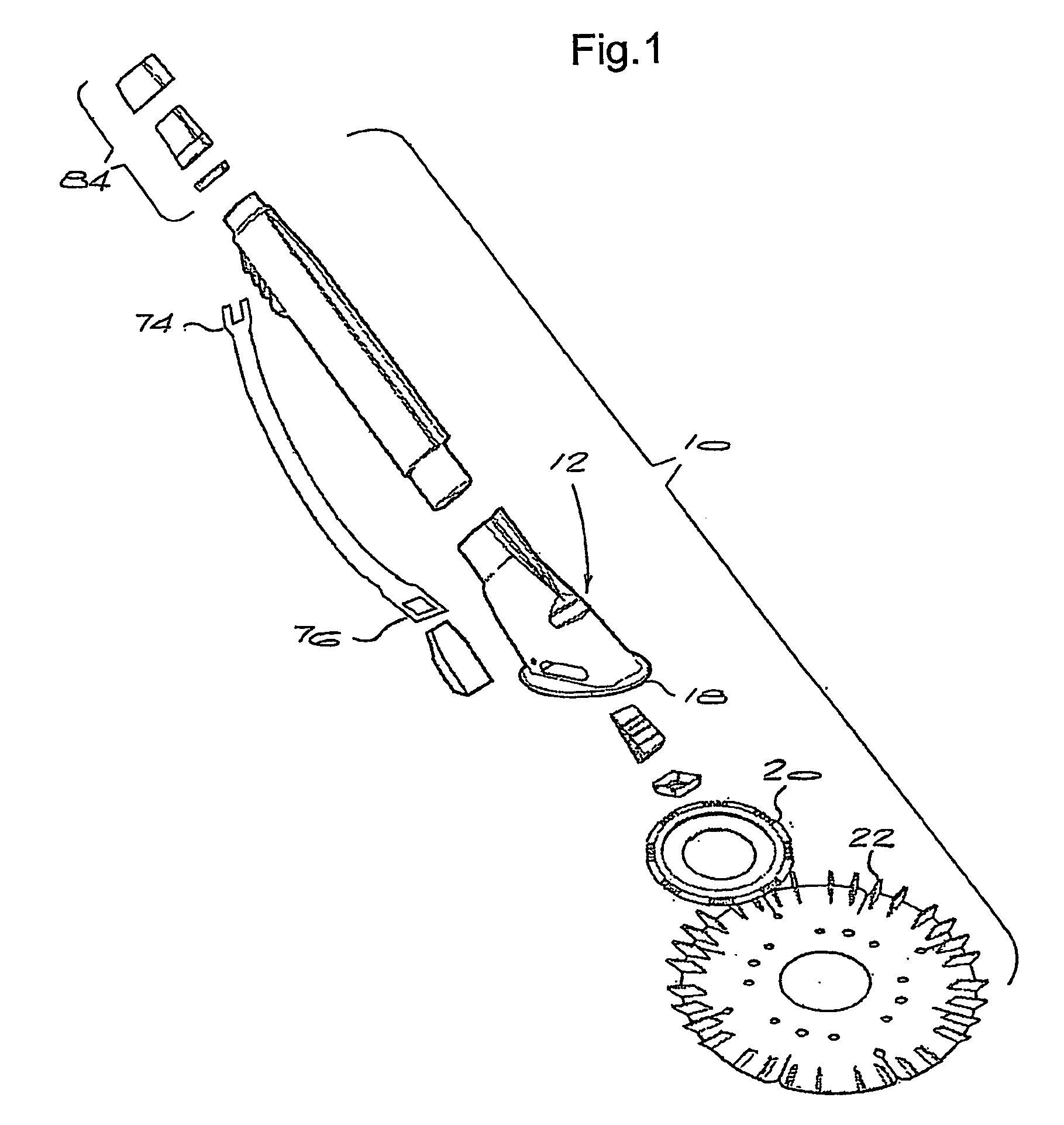

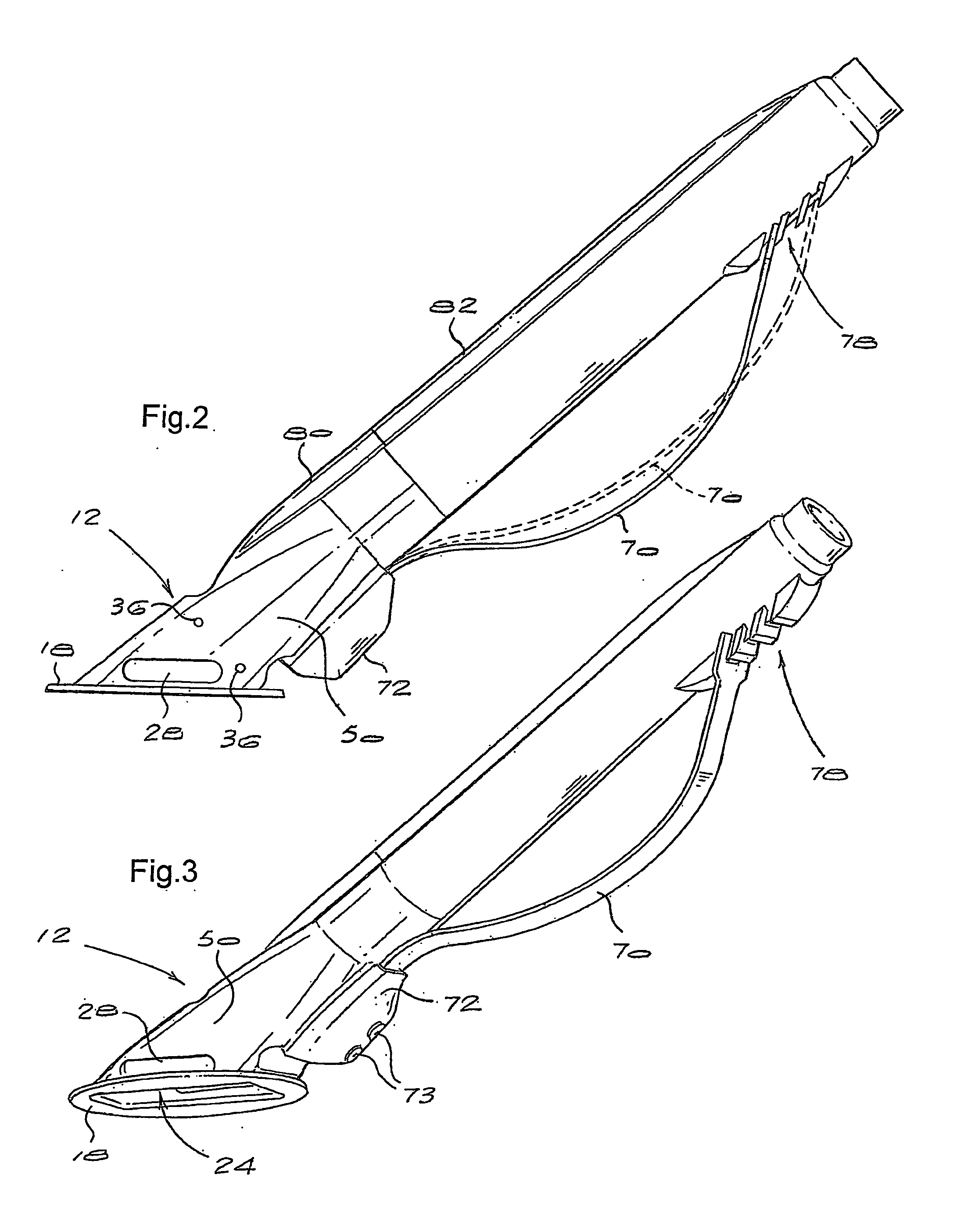

[0024]The drawings show a suction-type submerged surface cleaner 10 according to the invention.

[0025]The cleaner 10 includes a cleaner head 12 which defines a valve chamber 14 accommodating a wedge-shaped valve member or hammer 16. The cleaner head terminates at its operatively lower end in a circular foot 18 to which an annular polyurethane footpad 20 is fitted in use, with the inner extremity of a flexible polyurethane skirt 22 sandwiched between the foot and the footpad.

[0026]The foot 18 defines a generally rectangular entrance opening 24. Referring to FIG. 4, the entrance opening 24 leads to an entrance space 26 having slot-shaped openings 28 on opposite sides and leading to the valve chamber 14. An inlet to the valve chamber is provided by a central opening 30 in a cover 32 which spans across the operatively upper end of the entrance space.

[0027]The cover 32 is a separately moulded component with integral projections 34 which are clipped into holes 36 formed in the cleaner head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com