Metallic frame and method of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention provides a metallic frame and a method of making the same. The metallic frame usually employed in electronic devices such as mobile phones, personal digital assistants, and laptop computers.

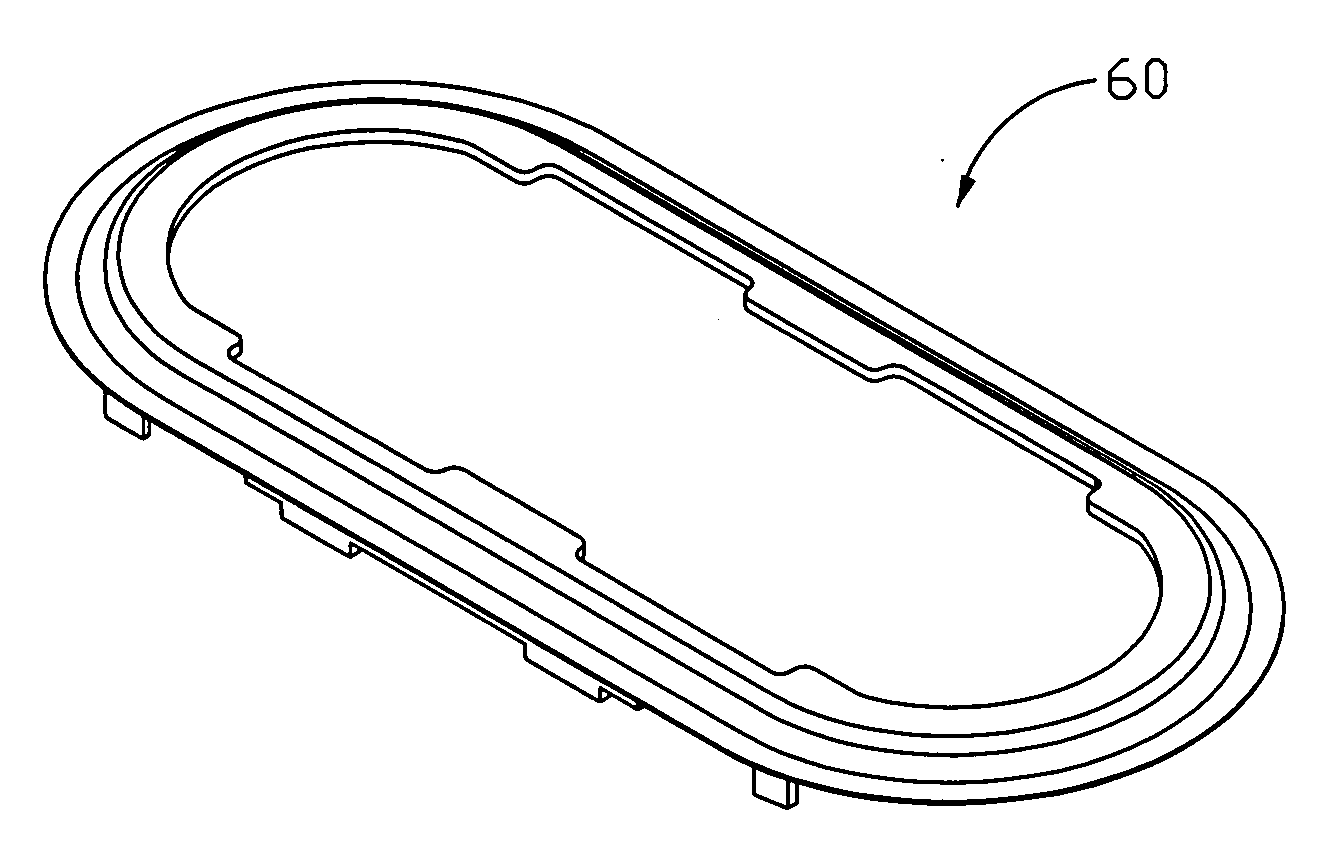

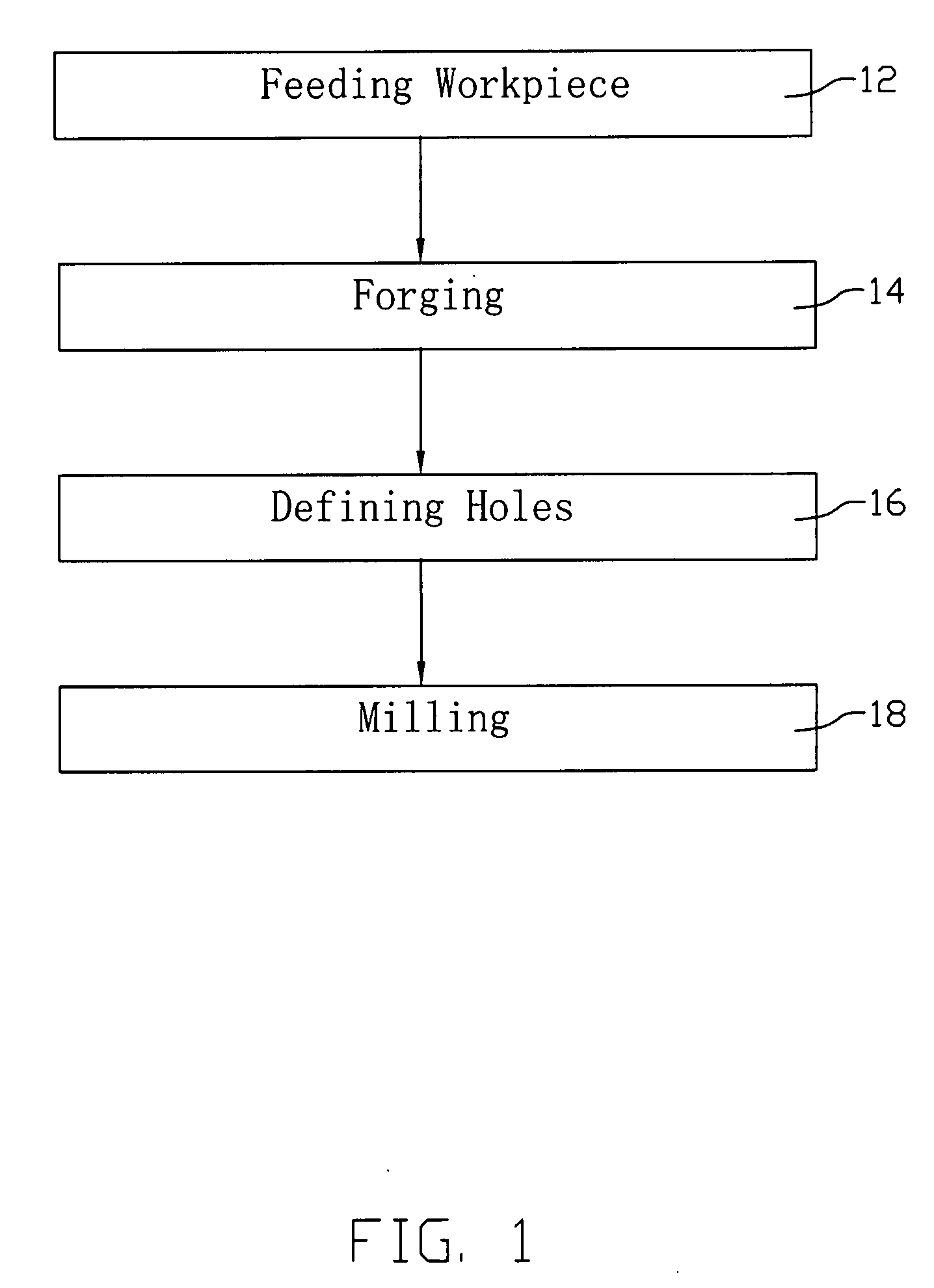

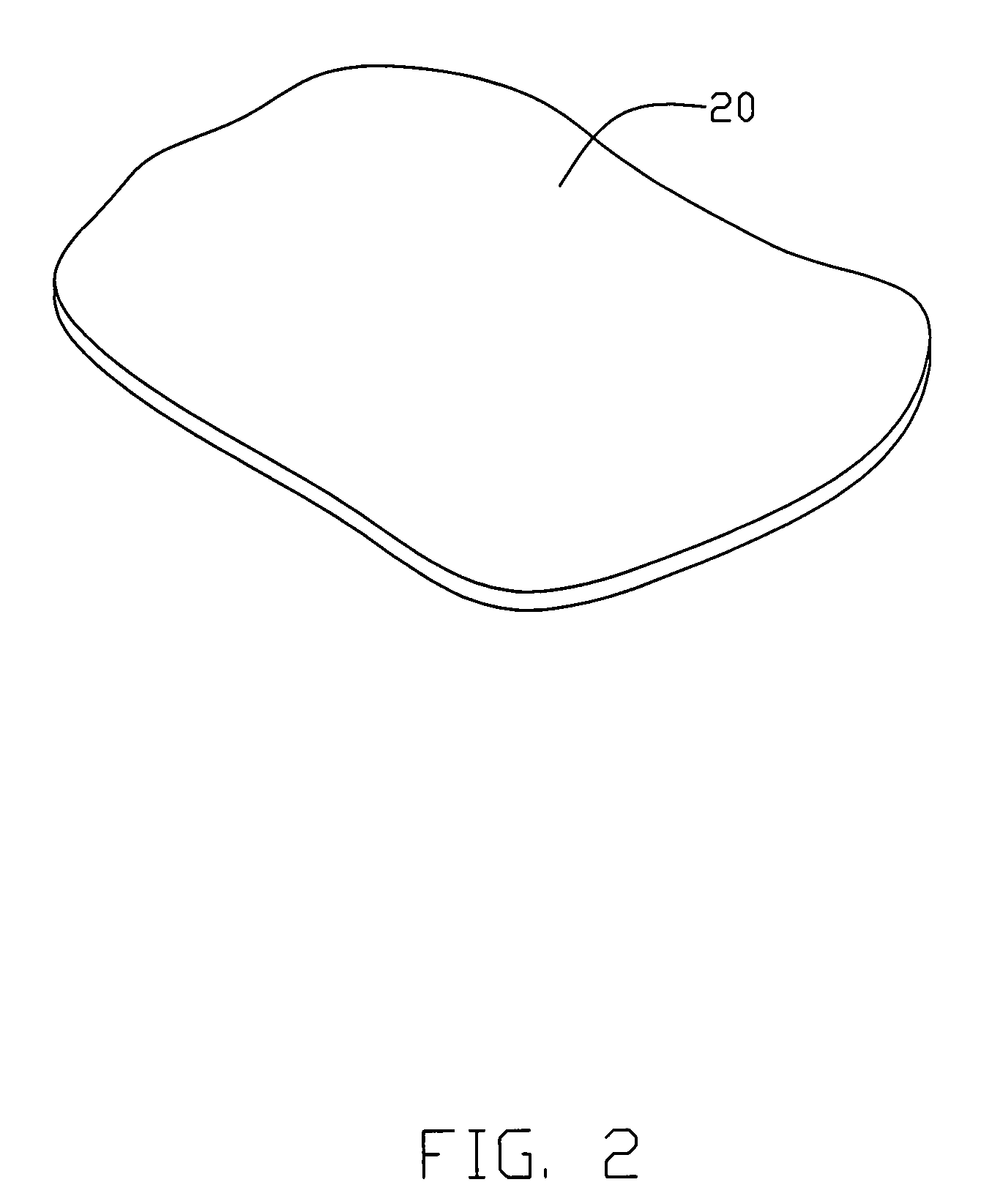

[0021]Referring to FIG. 1, the method of making the metallic frame includes the following:[0022](1) Feeding workpiece process 12: Referring to FIG. 2, a workpiece 20 is provided by cutting a steel sheet. A size of the workpiece 20 is determined according to a size and a shape of the frame design. In the embodiment, the workpiece 20 is made of SUS304I stainless steel;[0023](2) Forging process 14: Referring to FIG. 3, the workpiece 20 is forged several times by a forging equipment (not shown) with a forging mold (not shown), thereby yielding a preform 40. In the forging process 14, the workpiece 20 is managed without being heated by external heat. After the forging process 14, the preform 40 has a size and a shape similar to but a little different from the frame design. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com