System For Monitoring a Container

a container and monitoring system technology, applied in sustainable waste treatment, manufacturing tools, instruments, etc., can solve the problems of time and energy consumption of haulers, complicated coordination, and complicated tasks, so as to optimize the return on investment, reduce long-term costs, and eliminate costly instances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail, preferred embodiments of the invention with the understanding the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiments illustrated. The present invention will have the following main components and techniques for operation of the device.

[0039]For the purposes of the present disclosure, the term “waste” is used in its broadest sense and includes trash and recyclables. It not only includes items being destroyed or put in a landfill, such as trash, but also recyclables, such as paper, corrugation board, cardboard, etc.

[0040]The term “container” is also used in its broadest sense and can include bins, balers, compactors, etc. for holding waste and / or recyclables.

General Configuration of the System 10

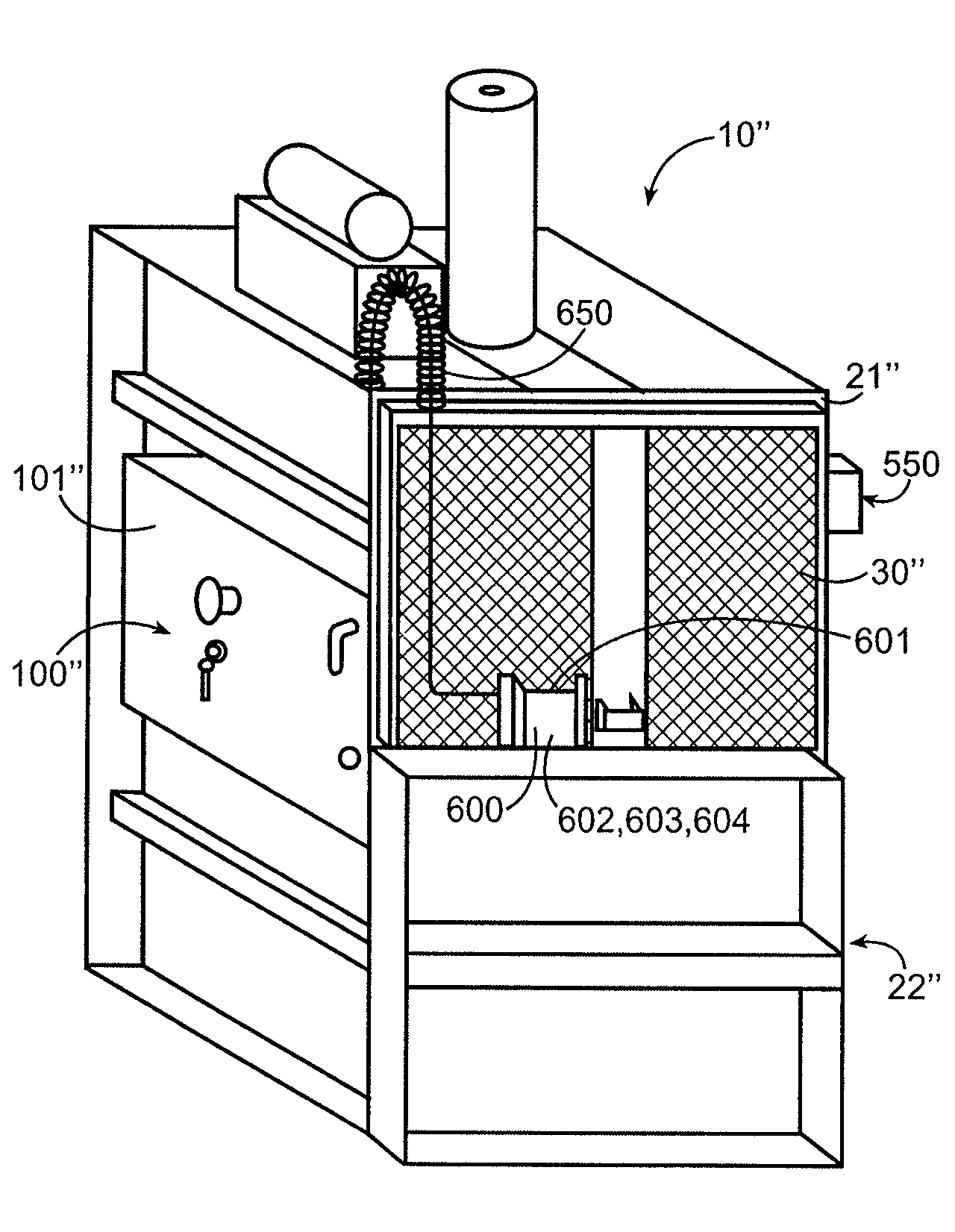

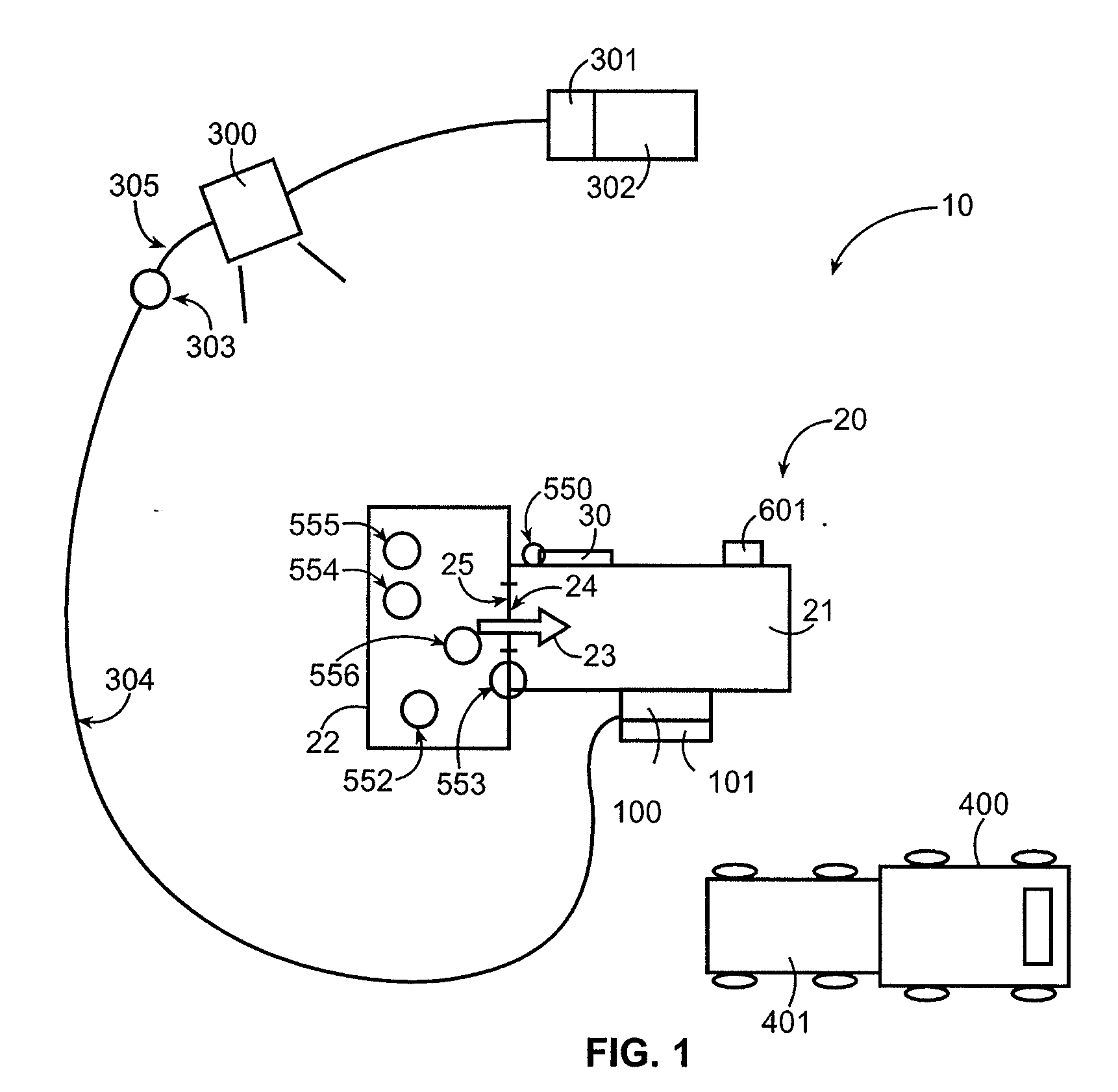

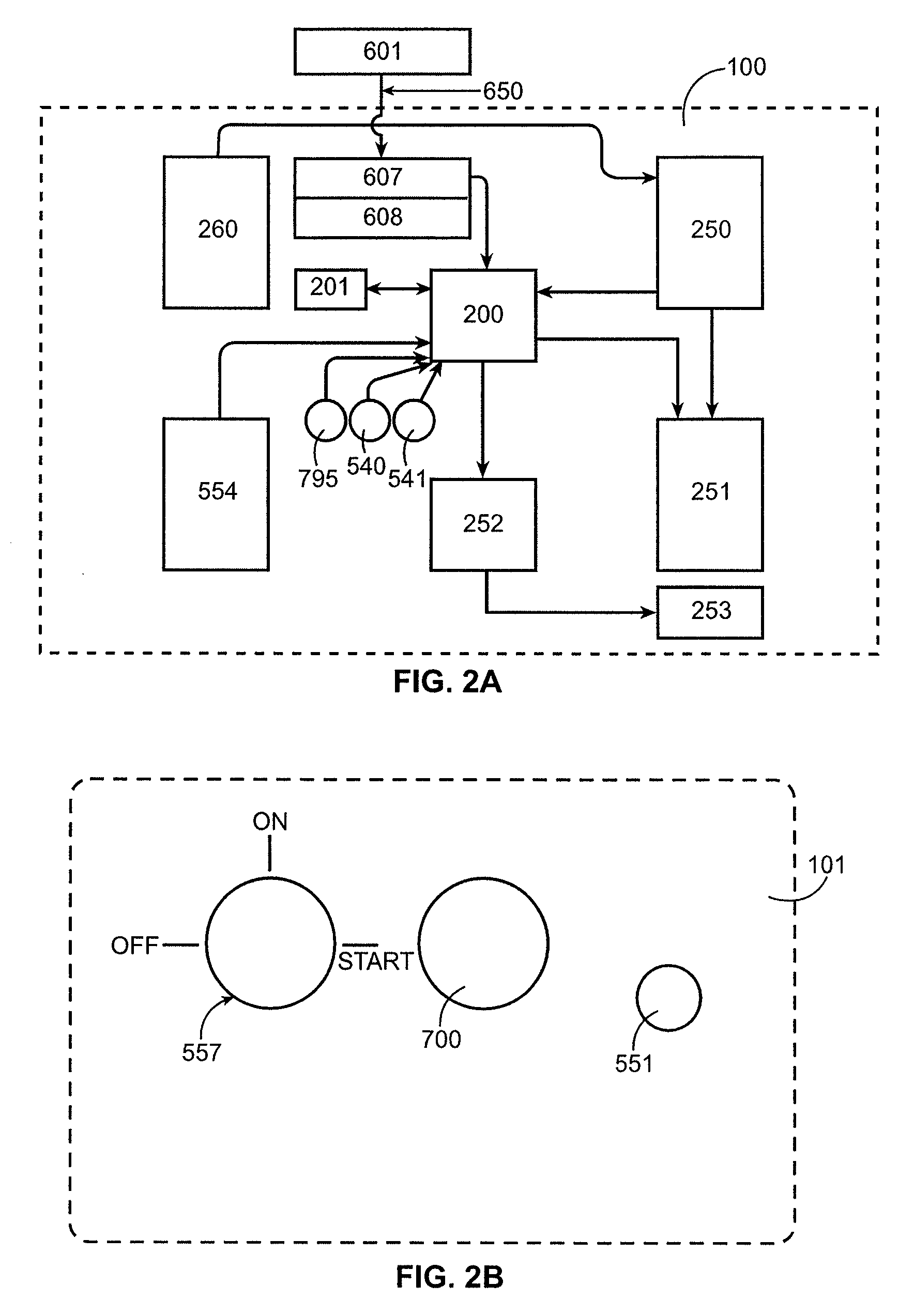

[0041]FIG. 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com