Vessel

a technology for liquid containers and containers, applied in the direction of containers, containers/bottles, rigid containers, etc., can solve the problems of splashing or overflow, large or sudden volume of liquid being expelled, and the ability of children to accurately control the pouring of small amounts of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]Referring to the drawings, various vessels are provided in accordance with embodiments of the present invention. The vessels may be used to hold and dispense fluids, such as liquid medications, liquid ingredients, engine oil, water, milk, paints or dyes.

[0065]It should be noted in the following description that like or the same reference numerals in different embodiments denote the same or similar features.

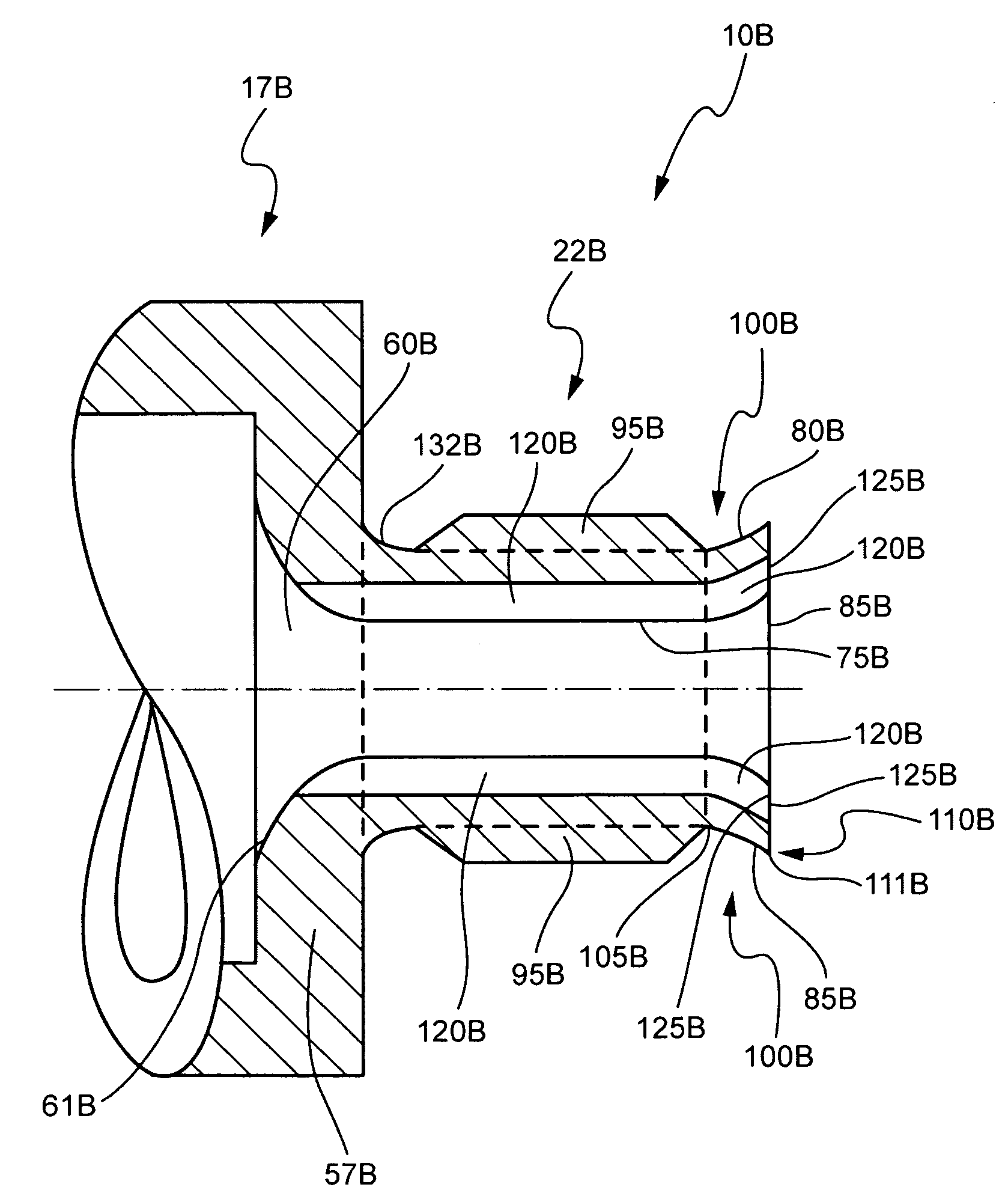

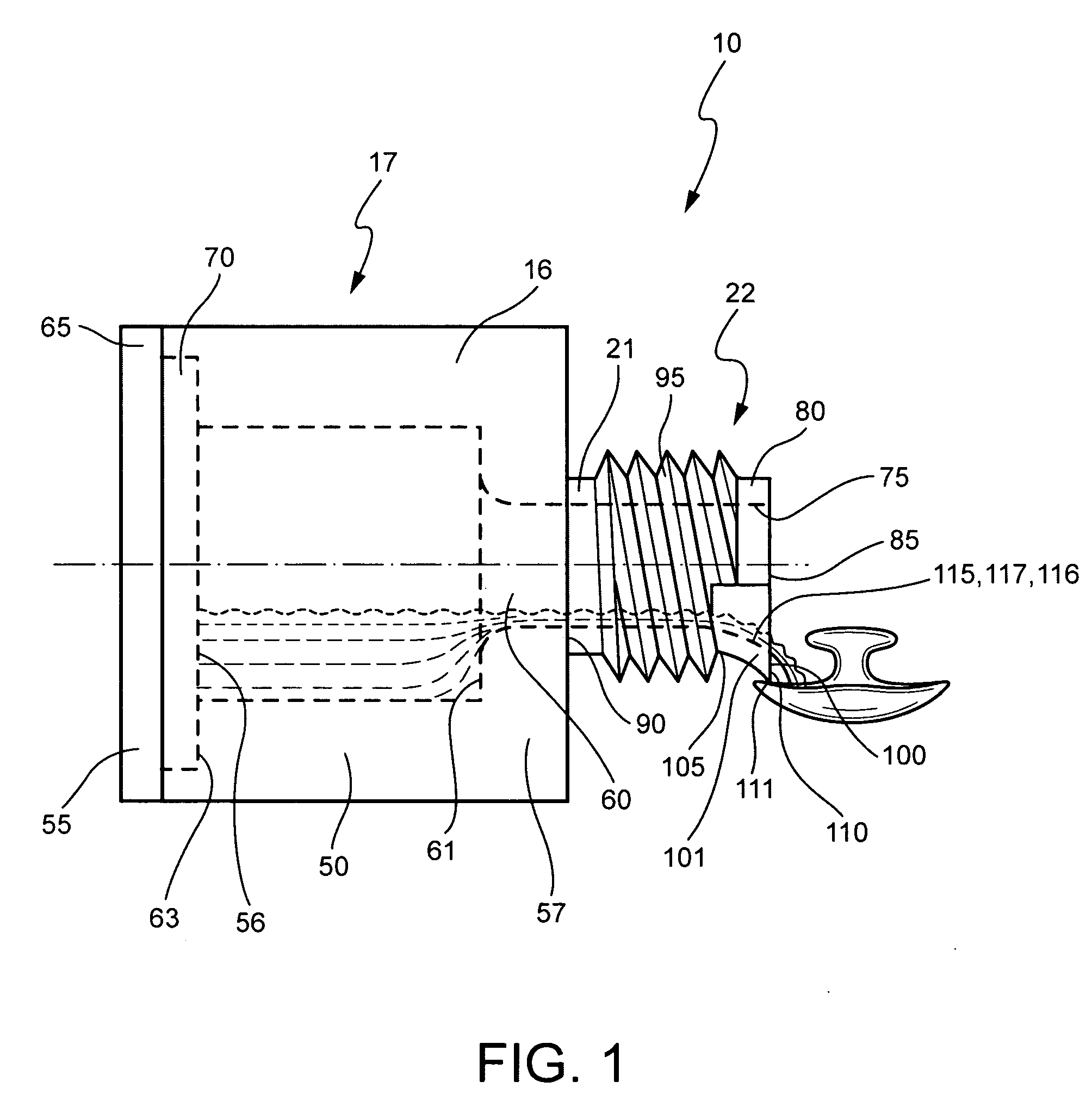

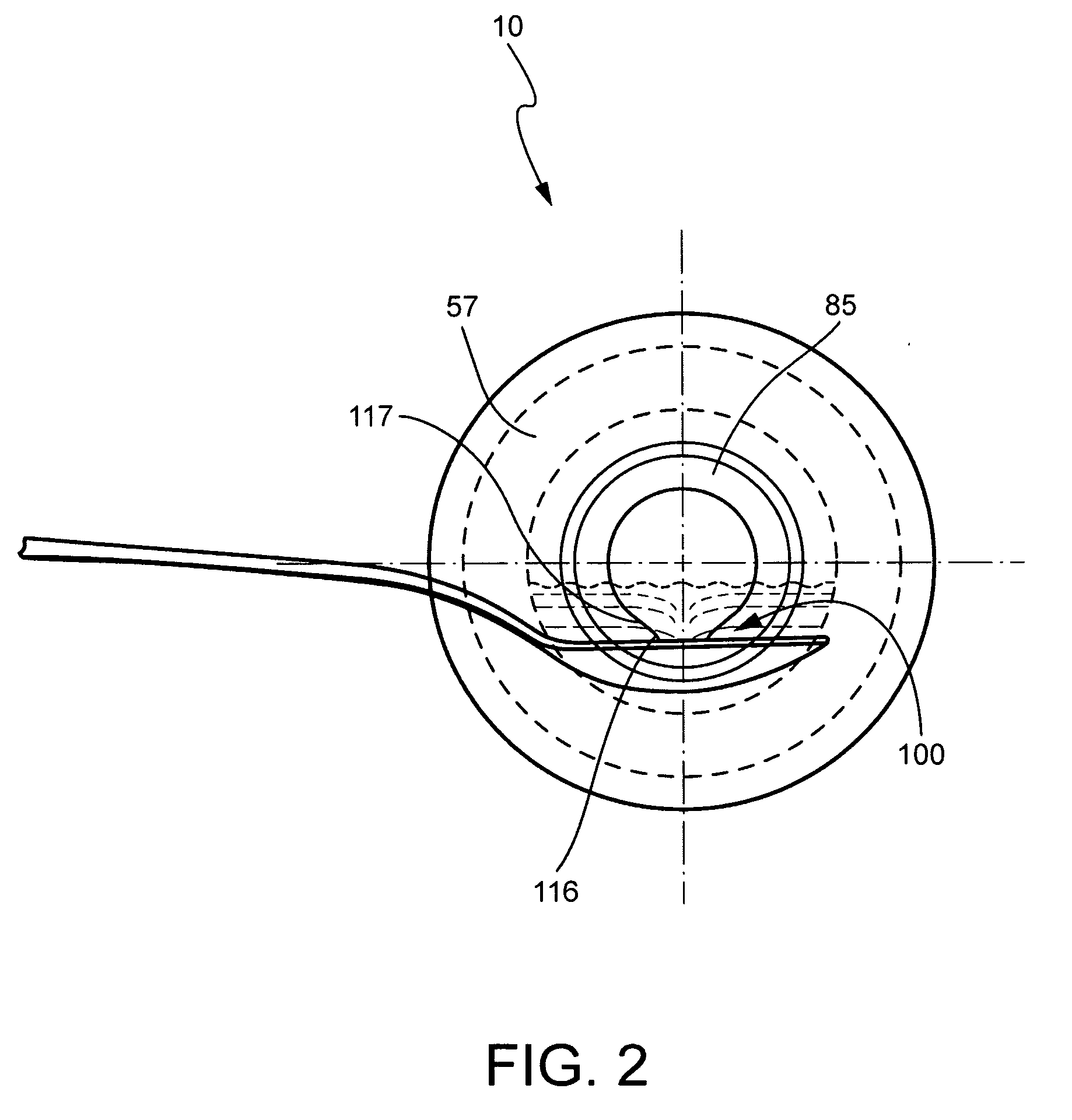

[0066]Referring to the embodiment of FIGS. 1 and 2, a vessel 10 is shown, comprising a relatively thick body wall 16 defining a body 17, and a thinner mouth wall 21 defining a mouth 22.

[0067]The body wall 16 comprises a tubular portion 50 and a base 55. The tubular portion 50 takes the form of a cylinder with an open bottom end 56 and a closed top end 57. A central aperture is located in the top end 57 forming a throat 60. The throat 60 is gradually curved where it opens at a bottom surface 61 of the top end 57. In another embodiment, the throat 60 is chamfered where it open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com