Method and apparatus for controlling engine exhaust sound for vehicles

a technology for controlling engine exhaust and vehicle exhaust, which is applied in mechanical equipment, machines/engines, gas passages, etc., can solve the problems that the conventional art apparatus does not produce a powerful exhaust sound in the engine starting region, and achieves powerful sound, good acceleration sound, and reduced back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

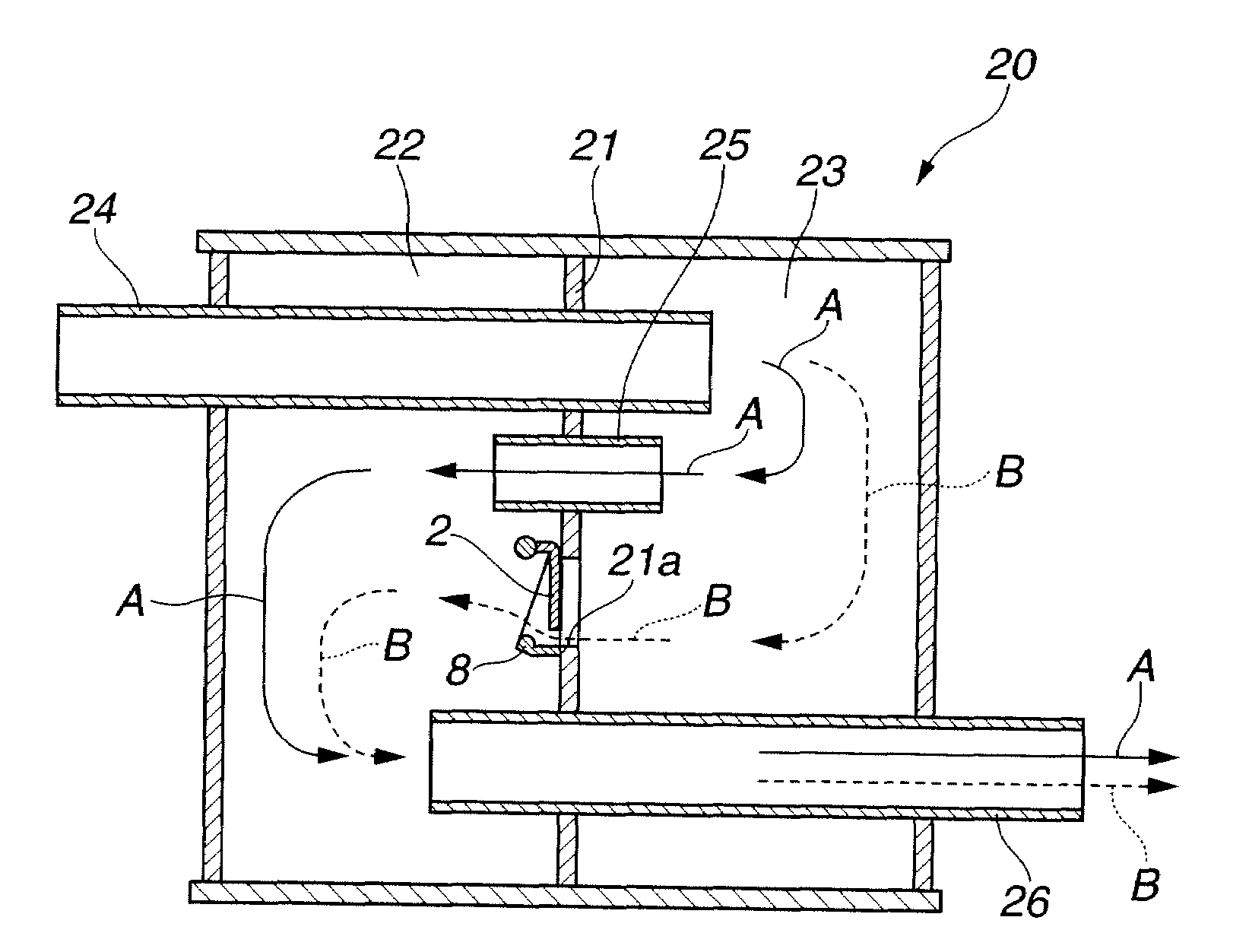

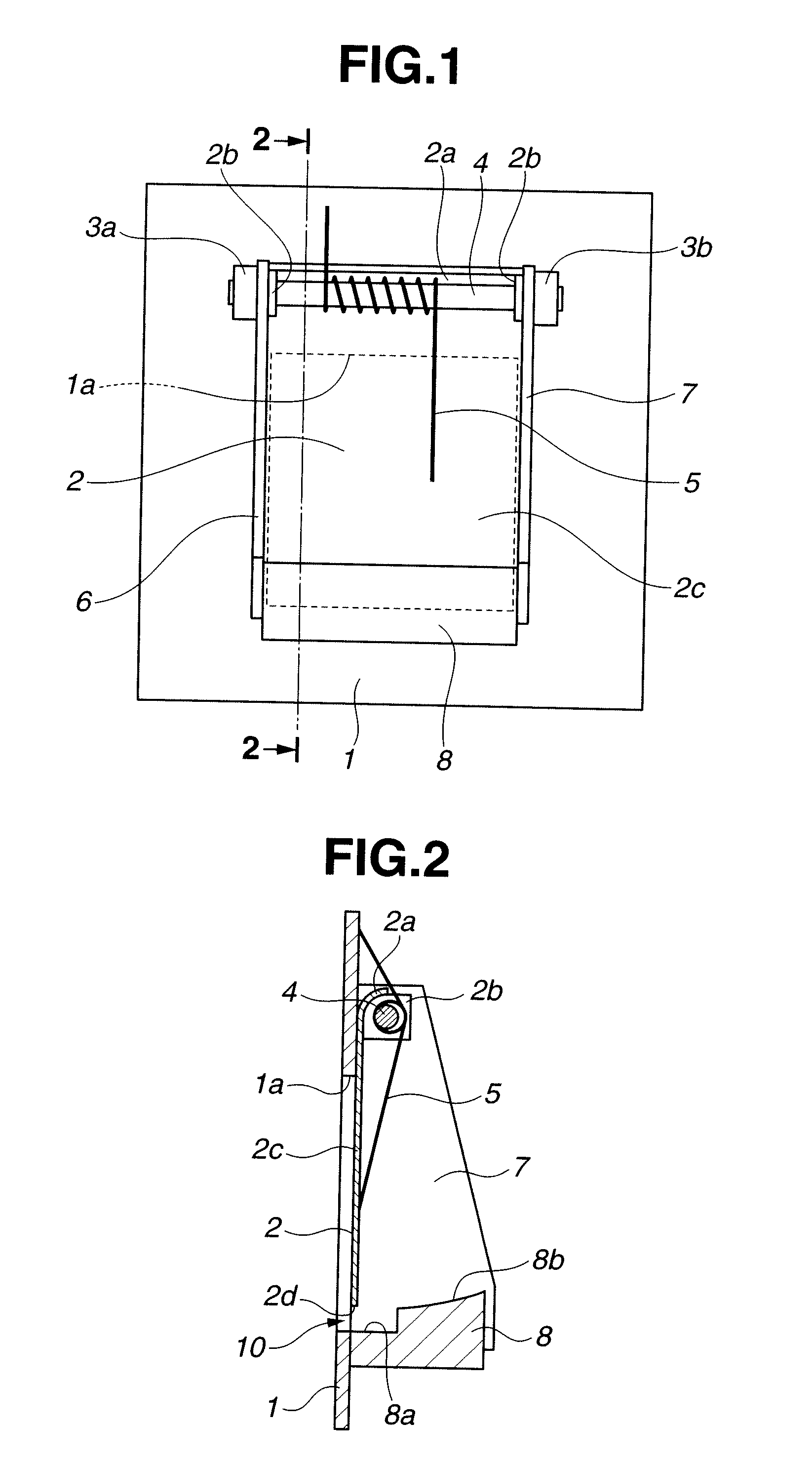

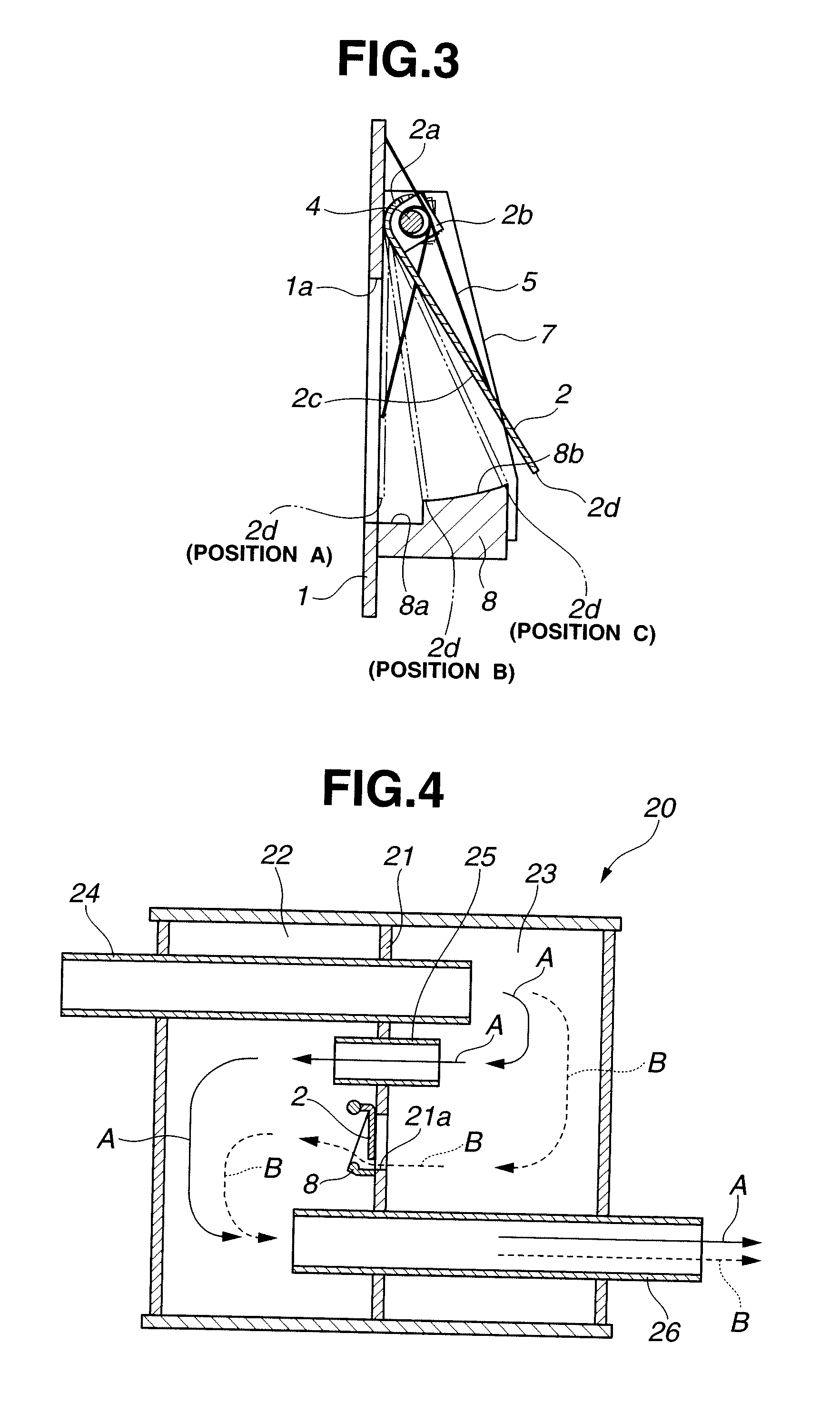

[0035]Referring to FIG. 1 to FIG. 3, an exhaust sound controlling apparatus for vehicles, according to an embodiment of the present invention, now is explained. The exhaust sound controlling apparatus includes a valve structure shown in FIG. 1 and FIG. 2. As shown in FIG. 1 and FIG. 2, the valve structure includes valve 2 that is disposed on baffle plate 1. Baffle plate 1 is disposed within a muffler as explained later which is connected to a vehicle engine. Baffle plate 1 divides an interior of the muffler into a plurality of expansion chambers which constitute an exhaust path through which a flow of exhaust gas from the engine passes. Baffle plate 1 is so arranged as to block the flow of exhaust gas in the exhaust path.

[0036]Baffle plate 1 includes a generally rectangular-shaped aperture la as shown in FIG. 1. Aperture la extends through baffle plate 1. Valve 2 is disposed on a downstream side surface of baffle plate 1 with respect to the flow of exhaust gas and so arranged as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com