Vertical bubble machine

a vertical and bubble machine technology, applied in toys, entertainment, etc., can solve the problems of contaminating the surface area, wasting a significant amount of bubble fluid, and generally undesirable to blow bubbles in the horizontal direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

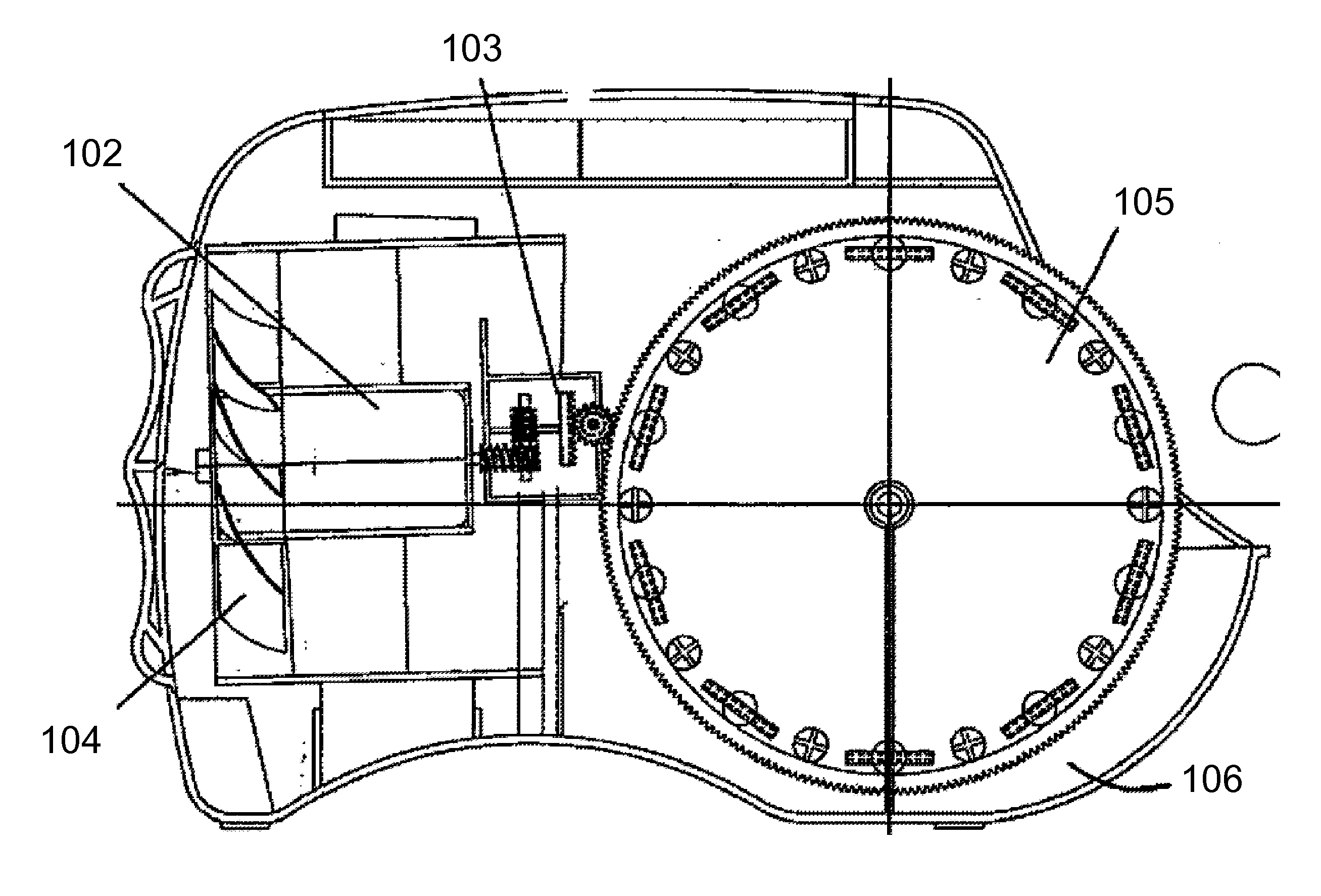

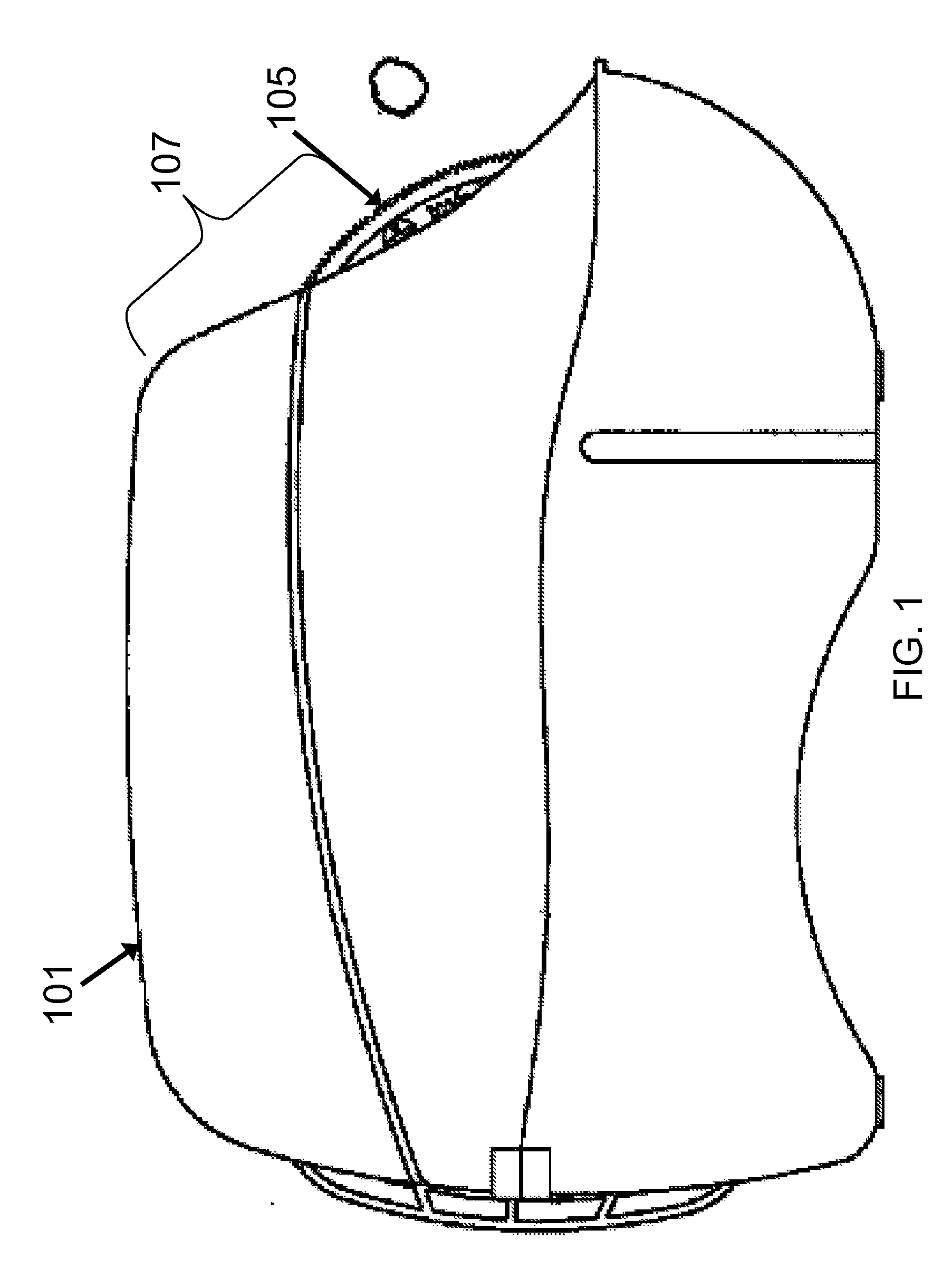

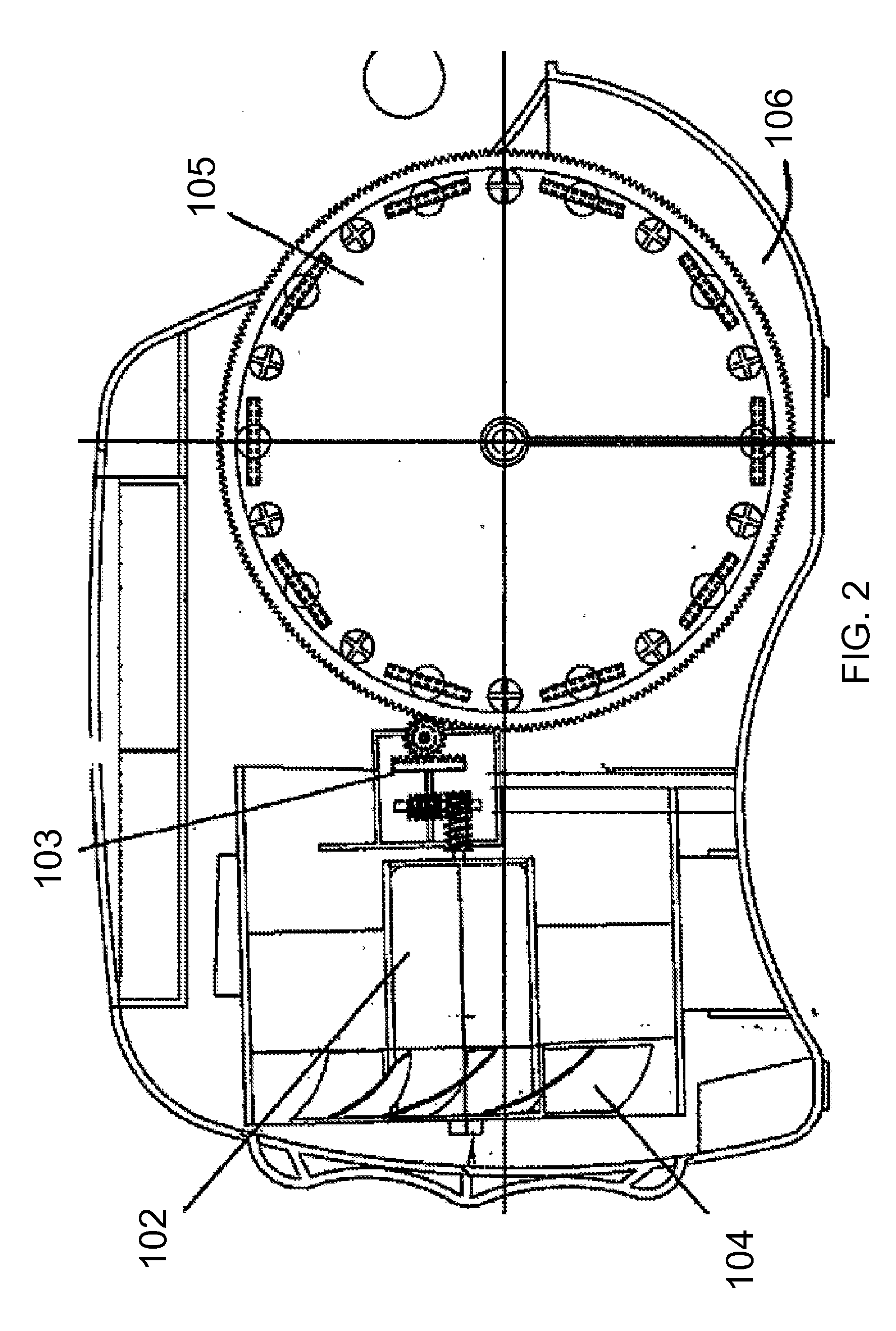

[0011]The present invention reverses the configuration of the motor and fan and turns the bubble wheel at right angles to significantly reduce the size of the bubble machine. In the prior art machine above, the configuration is fan>motor>wheel, and the plane of the bubble wheel is in-line with the axis or plane of the fan and motor. By putting the wheel at right angles, and / or by reversing the motor and fan configuration (motor>fan>wheel), and / or by sitting the fan wholly or partially inside the wheel, the current invention significantly reduces the footprint of the device.

[0012]According to one aspect of the present invention, a compact size bubble generating machine is provided, that comprises a housing having an upper opening; a bubble generator positioned inside the housing and adjacent to the upper opening; an impeller positioned inside the housing; and a motor positioned inside the housing and operatively coupled to the impeller and the bubble generator. In this variation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com