Autonomous Ventilation System

a technology of ventilation system and automatic control, which is applied in ventilation system, heating type, stove or range, etc., can solve the problems of needlessly wasting energy not only in the operation of ventilation system, and achieve the effect of reducing or eliminating at least some of the disadvantages and problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

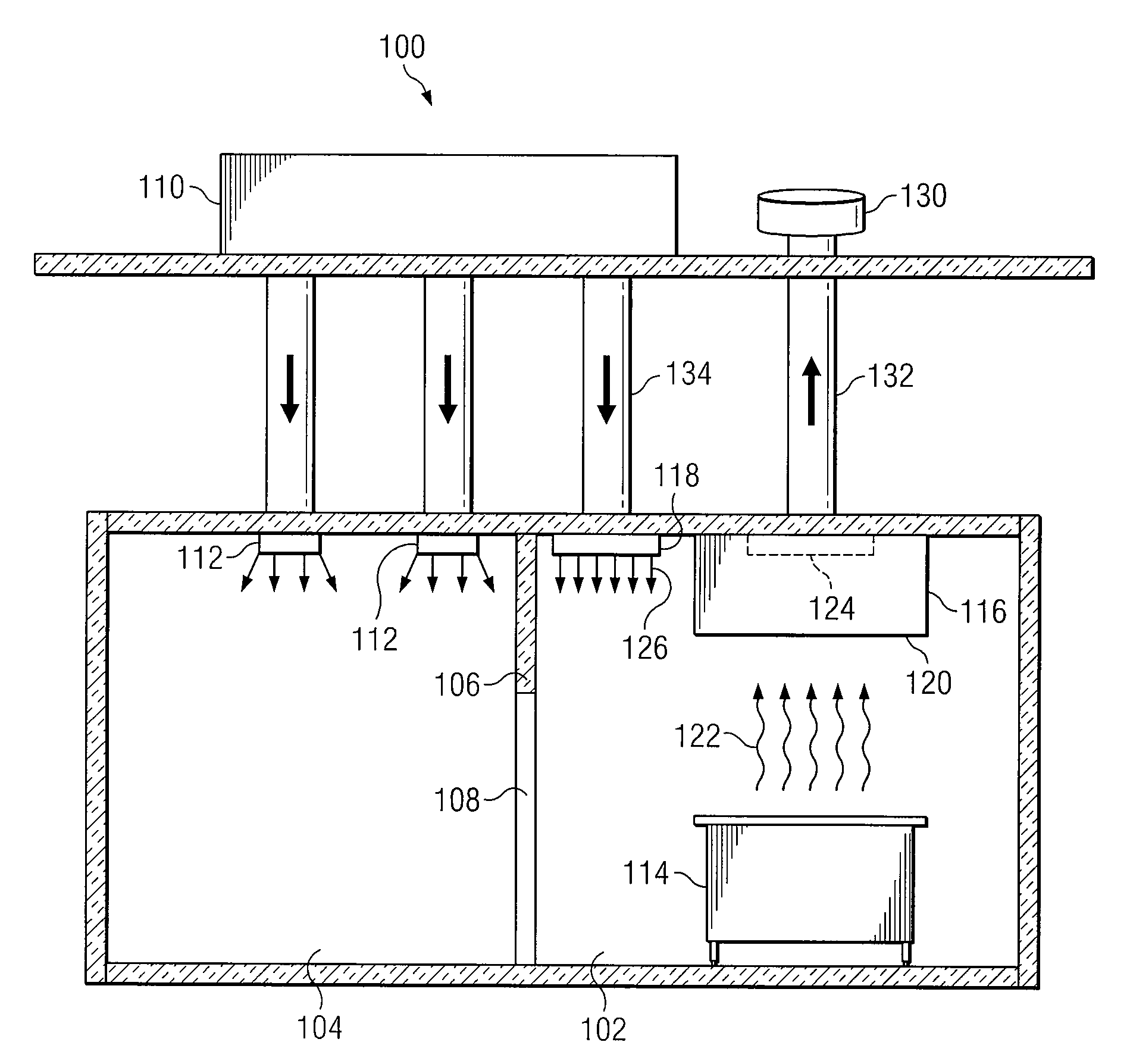

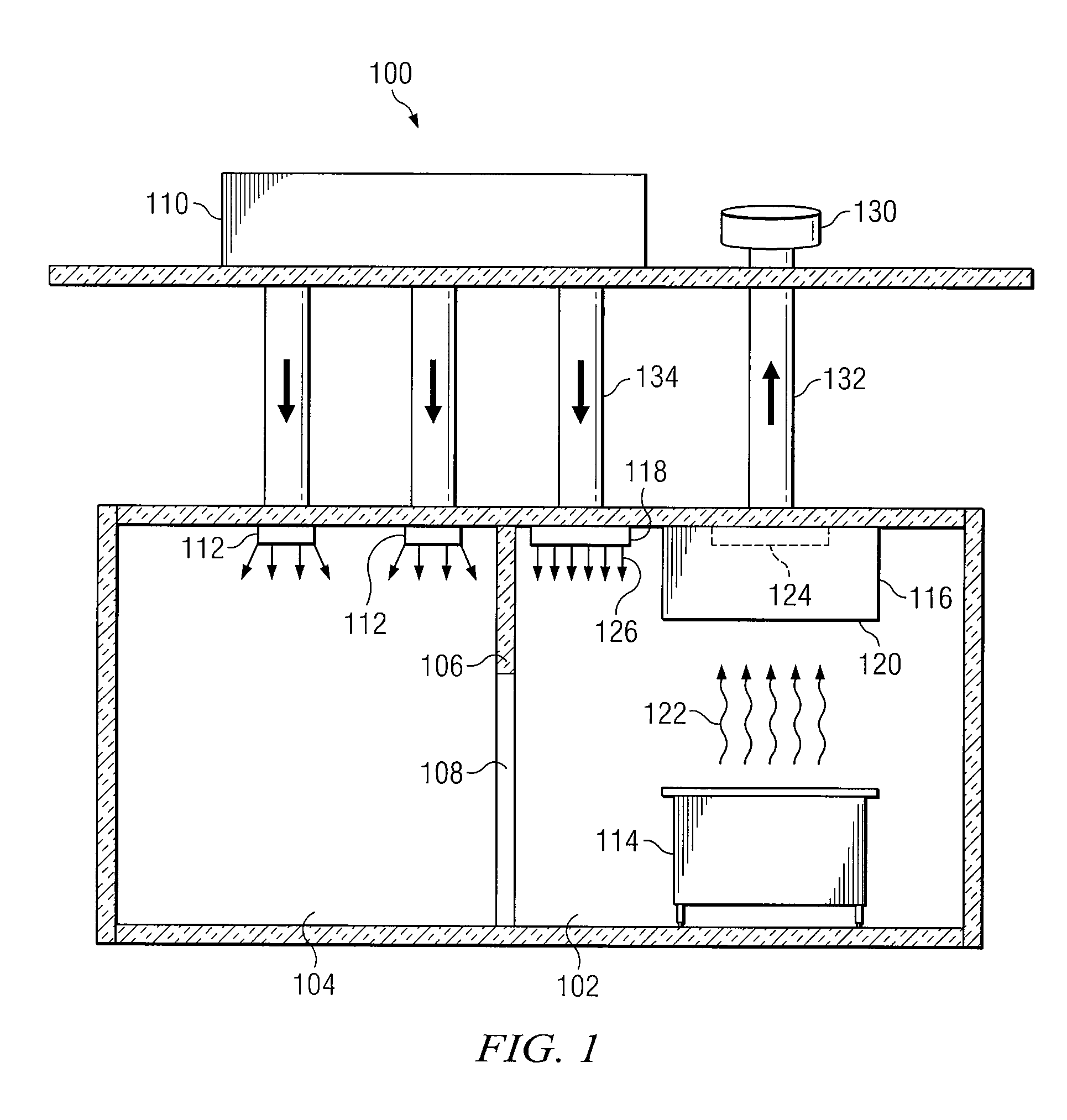

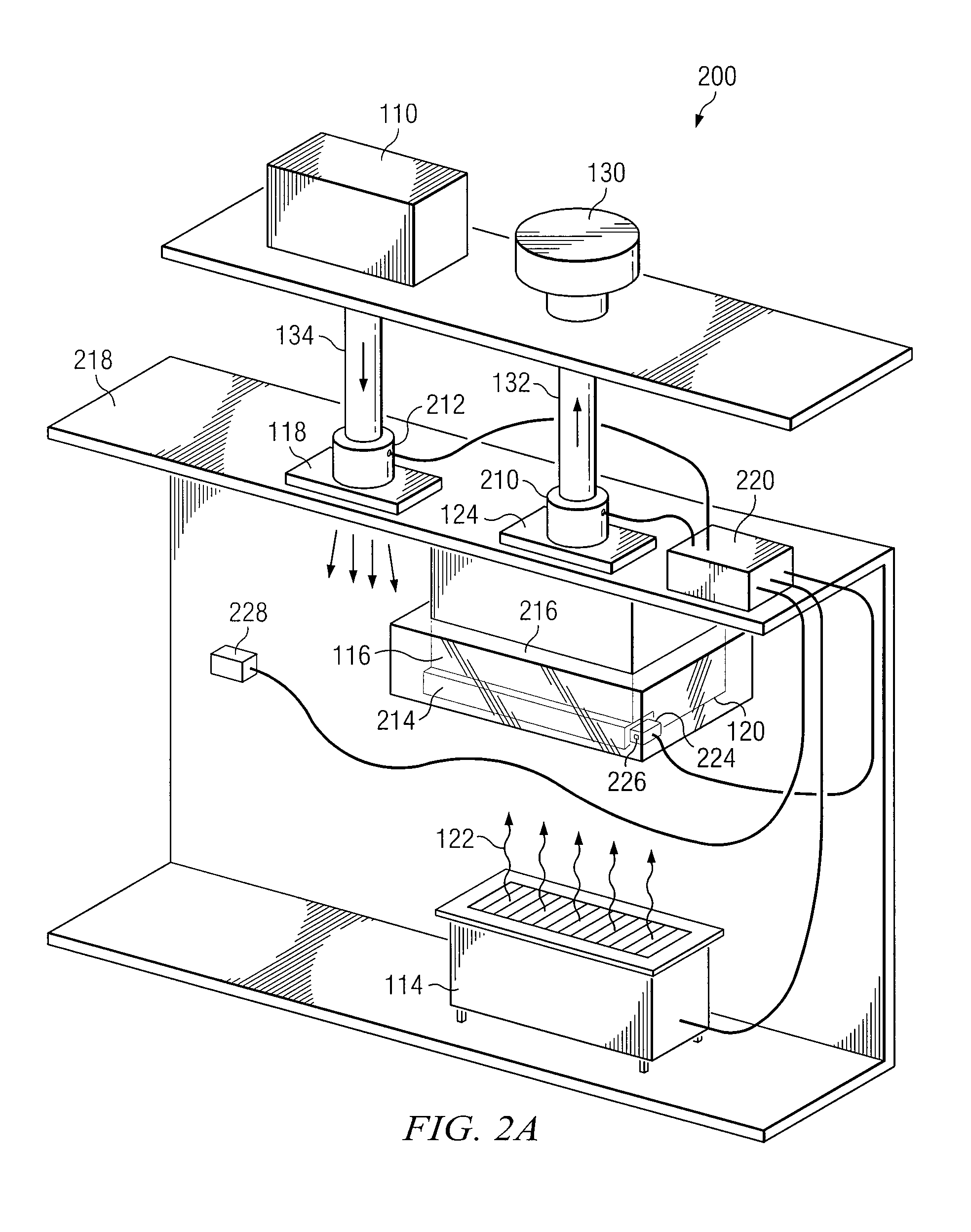

[0015]FIG. 1 depicts a facility 100 where a particular embodiment may be utilized. Facility 100 may be a restaurant, for example, that includes a kitchen 102 and at least one adjacent room 104 separated by a wall 106. Wall 106 contains a doorway 108 that allows access between kitchen 102 and adjacent room 104. Facility 100 also includes an HVAC system 110 that provides conditioned air to the interior of facility 100 via interior vents 112. Kitchen 102 includes one or more pieces of cooking equipment 114, an exhaust hood 116, a ceiling supply air vent 118, and a ceiling exhaust vent 124. Examples of cooking equipment 114 include, but are not limited to, stoves, cooktops, ovens, fryers, and broilers. Exhaust hood 116 is oriented such that a downward-facing opening 120 is operable to direct an air contaminant 122 associated with the operation of cooking equipment 114 through ceiling exhaust vent 124 and ultimately out an exterior exhaust vent 130 via an exhaust duct 132. Air contaminan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com