Paper roll dispenser

a dispenser and paper roll technology, applied in the field of tissue roll mounts, to achieve the effect of reducing the incidence of tissue damage, minimizing the force, and facilitating the removal of the spent roll and the replacement by a new on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

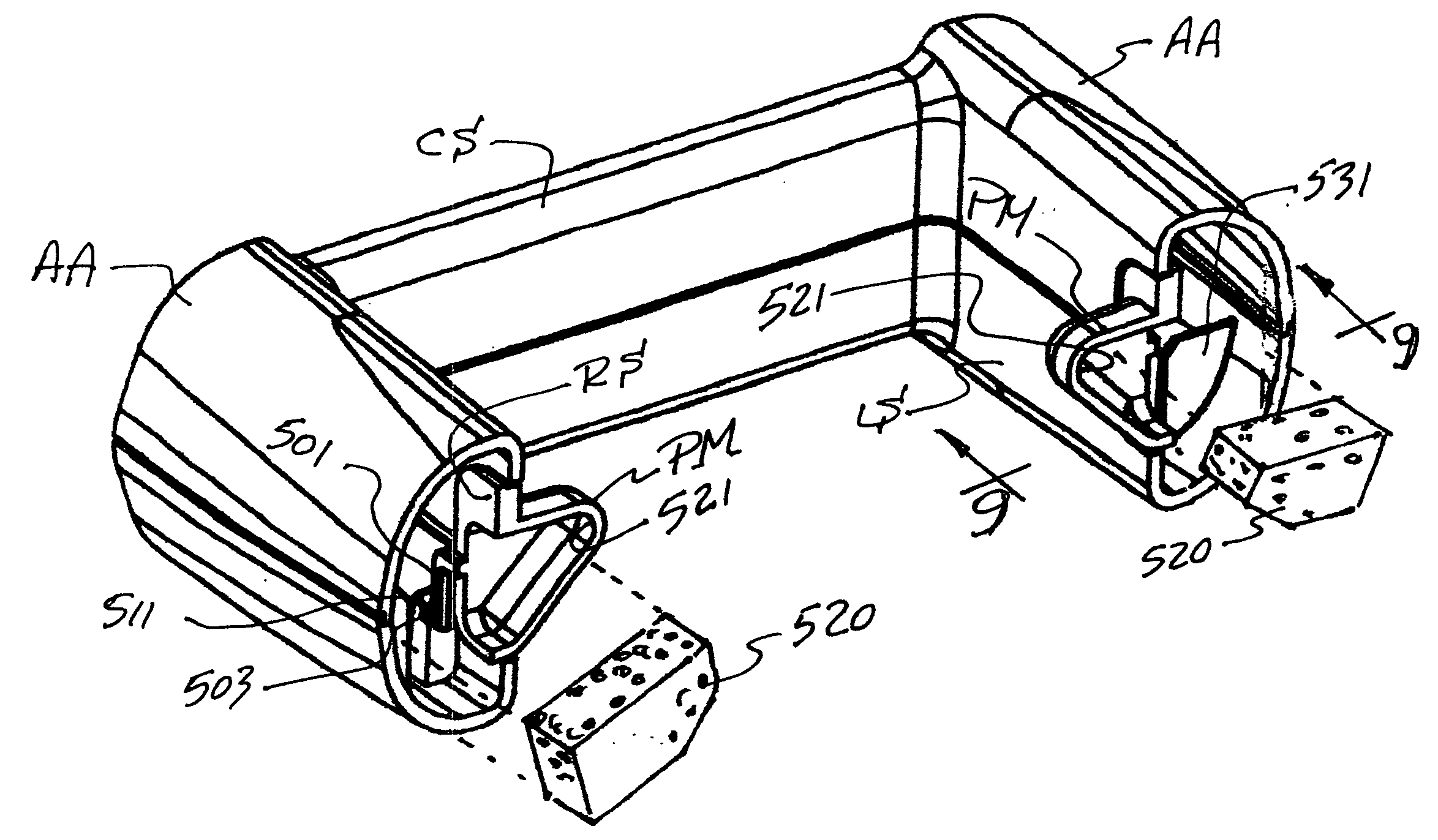

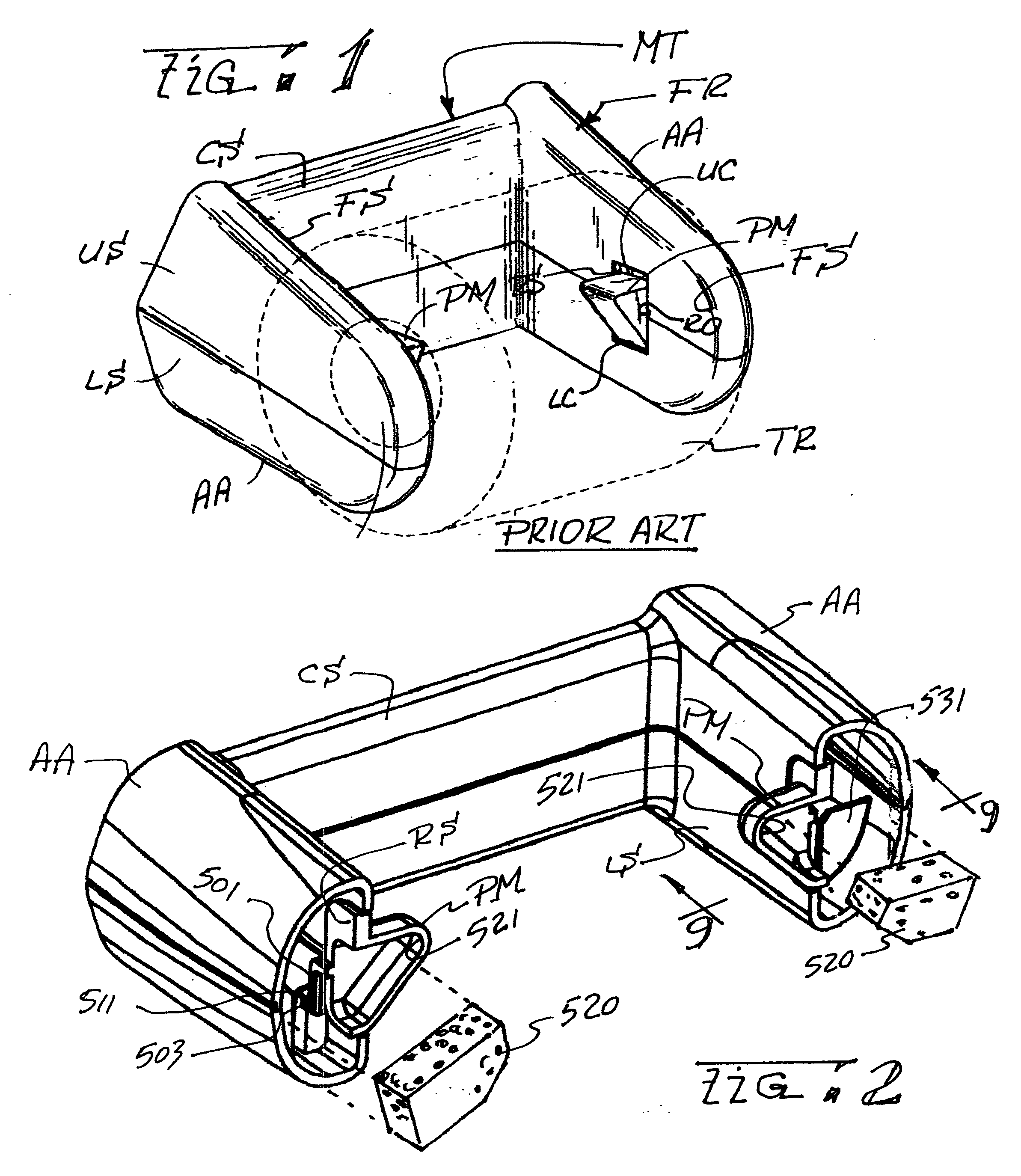

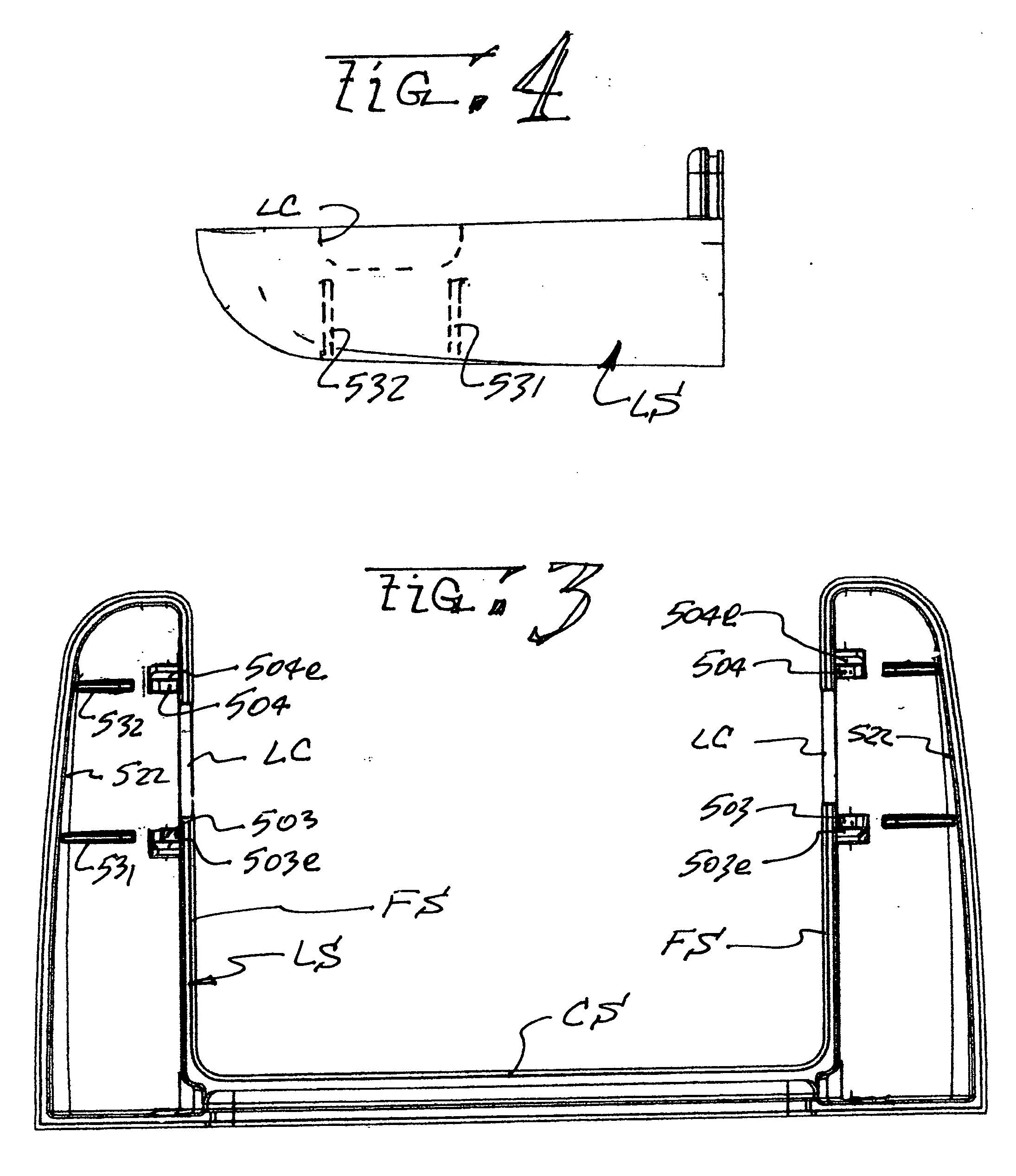

[0022]While I have earlier disclosed several inventive variants of a tissue roll mount assembly in my prior U.S. Pat. Nos. 6,189,828 and 6,386,478 respectively issued on Feb. 20, 2001, and May 14, 2002, and while the instant invention is useful with both the foregoing teachings its operative aspects are best explained in association with the illustrations in the '478 patent incorporated herein by reference and exemplified by the prior art illustration shown as FIG. 1. As shown in this illustration, a tissue roll mount assembly generally shown at MT comprises a generally U-shaped hollow frame FR formed by joining the peripheral edge of a hollow upper frame shell US to the periphery of a lower shell LS to cooperatively form a central structure CS conformed for attachment to a wall (not shown). A pair of hollow arm assemblies AA extending in cantilever from the ends of the central structure CS then form opposed face surfaces FS spaced to receive a tissue roll TR therebetween. Each of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com