Method of combining heat pipe and fins and the assembly thereof

a technology which is applied in the direction of lighting and heating apparatus, semiconductor/solid-state device details, soldering apparatus, etc., can solve the problems of tin affecting the defective ratio of manufacture, the contact area of heat pipe and fins is important, etc., and achieves the effect of fast and easy combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

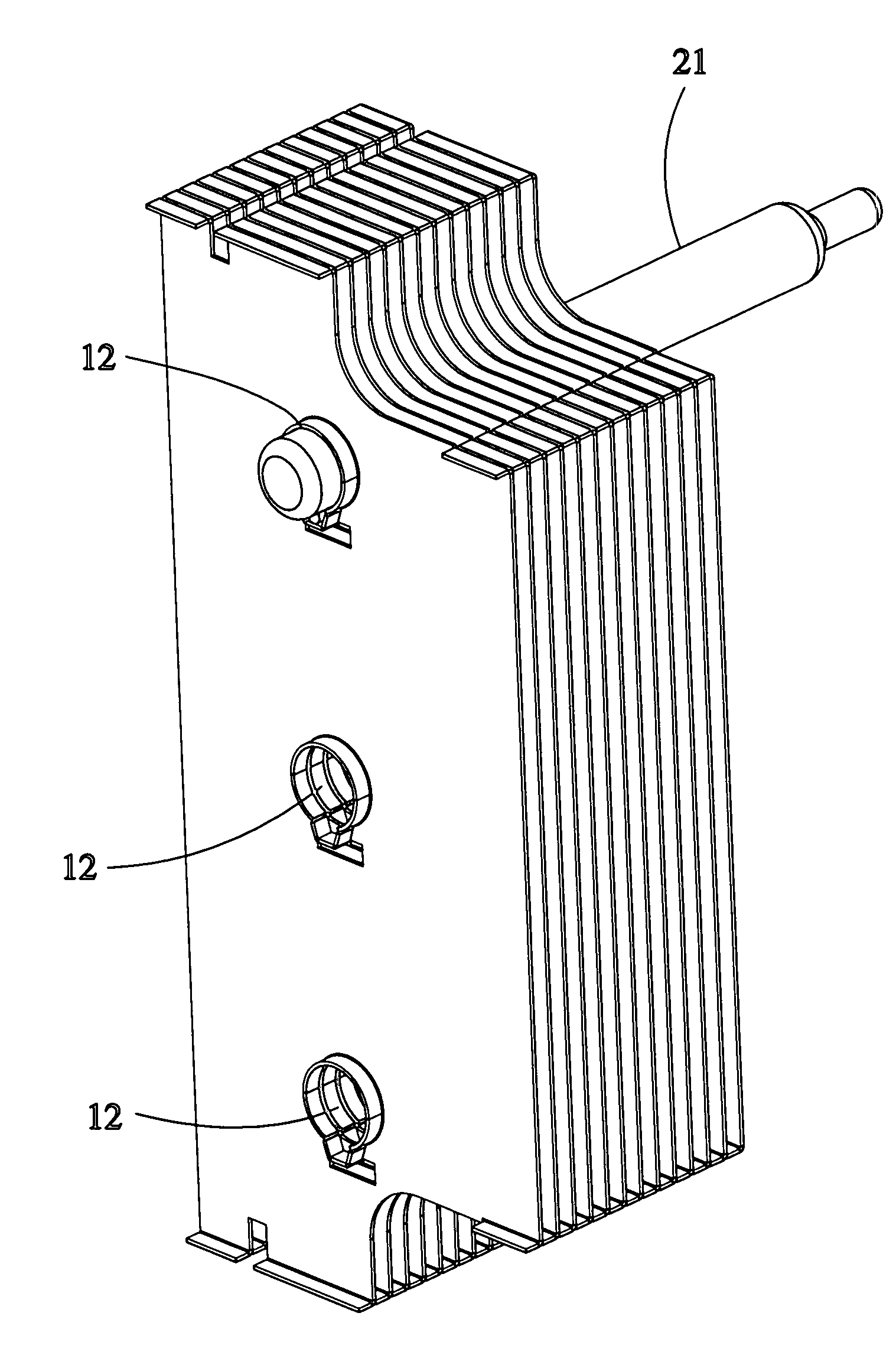

[0021]The present invention only provides one heat pipe 21 inserted into through hole 12.

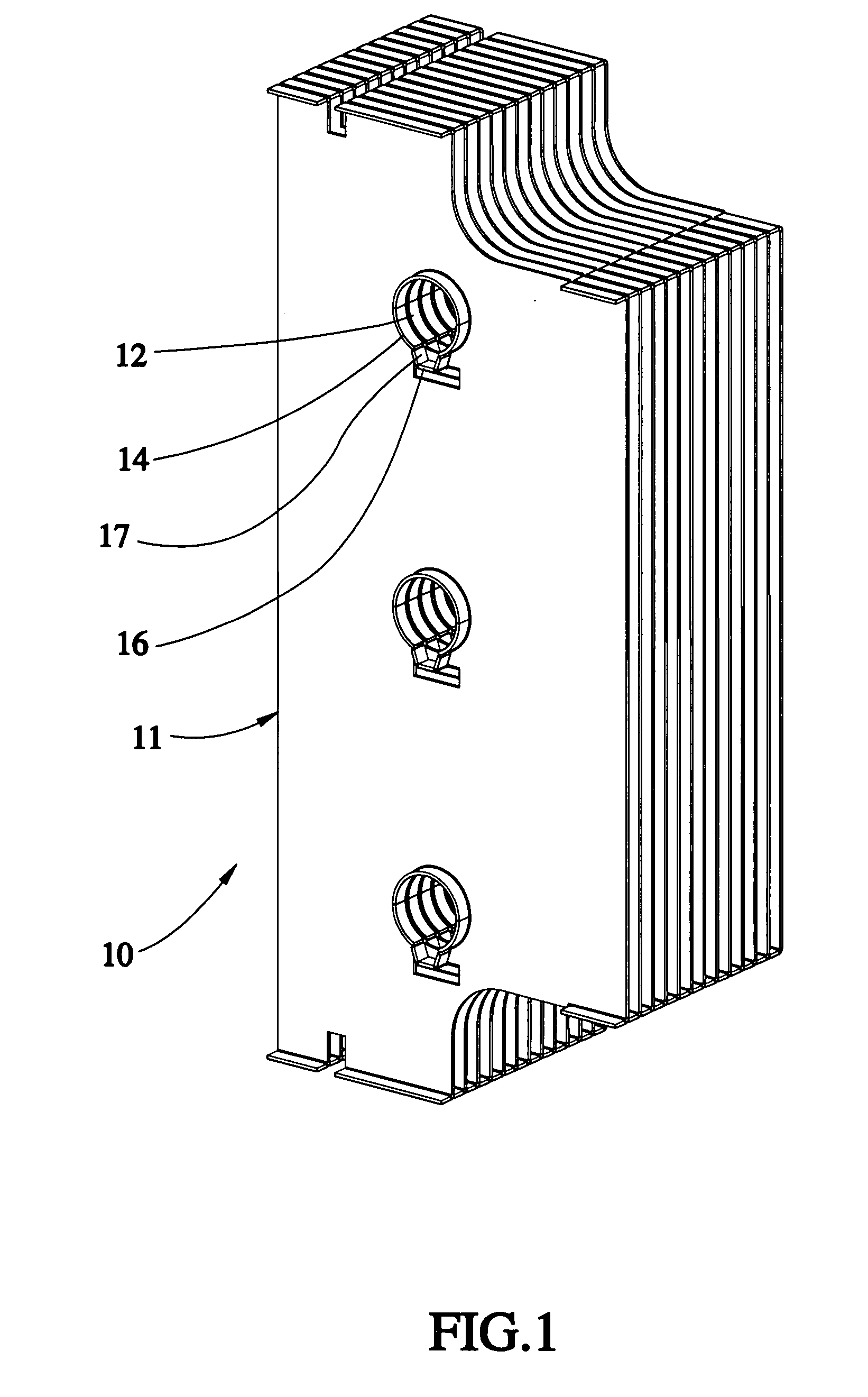

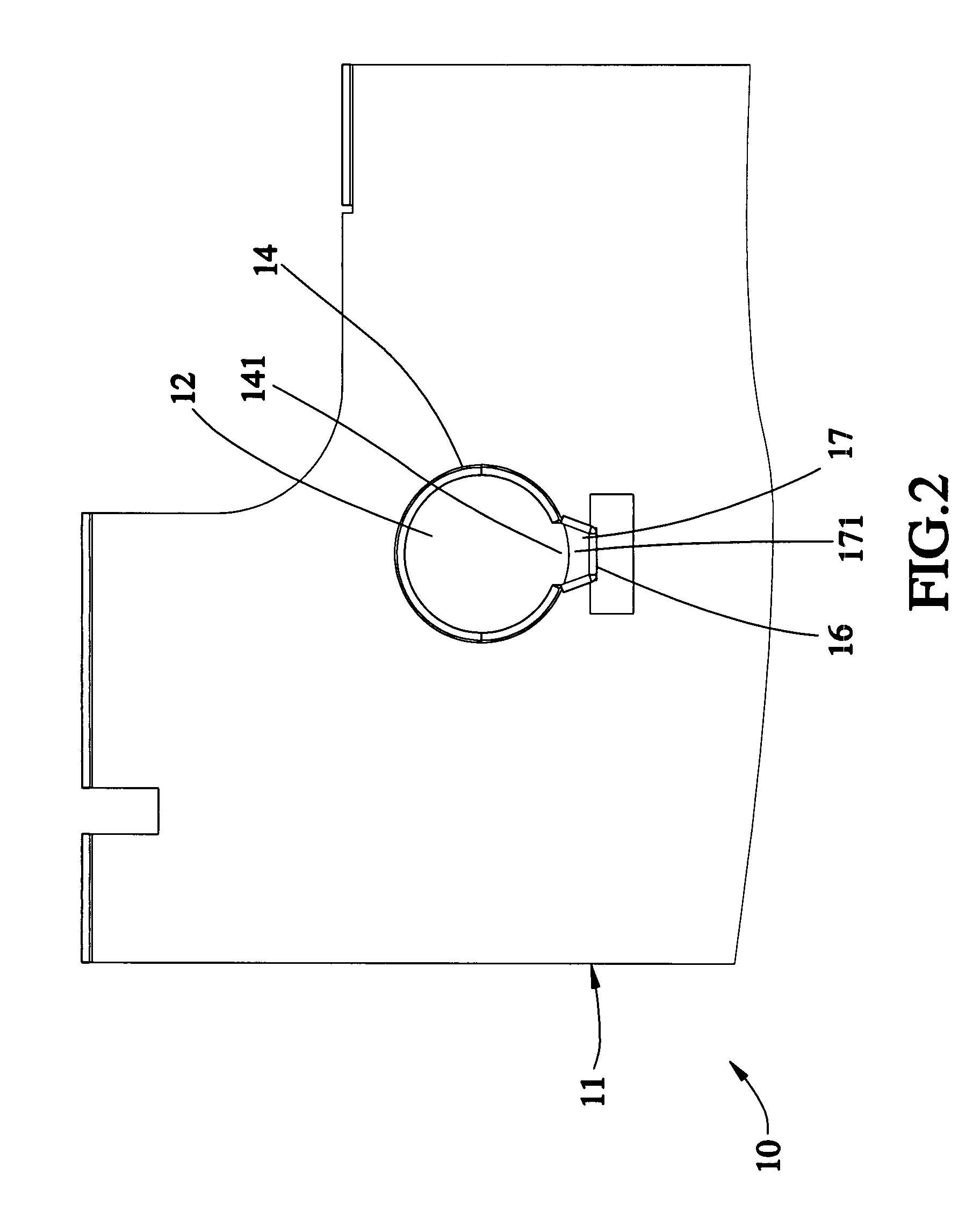

[0022]As shown in FIG. 1 to FIG. 7, a method of the first preferred embodiment of the present invention includes the following steps:

[0023]a) Preparation of a plurality of fins 11 and heat pipes 21: The fins 11 are stacked, each of which has a plurality of holes 12. The heat pipes 21 may pass through the holes 12 of the fins 11 respectively. Each of the fins 11 has an extending wall 14 around each of the holes 12 respectively. Each of the extending walls 14 has a first opening 141. Each of the fins 11 has a lateral plate 16 in front of each of the first opening 141 of the extending wall 14. Each of the lateral plate 16 has a receiving portion 17 with a second opening 171 aligned with the first opening 141. The fins 11 are against distal ends of the extending walls 14 and lateral plates 16 of the neighboring fins 11. The extending walls 14 and the lateral plates 16 on each of the fins 11 have the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| widths | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com