Non-sooting containerized candle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

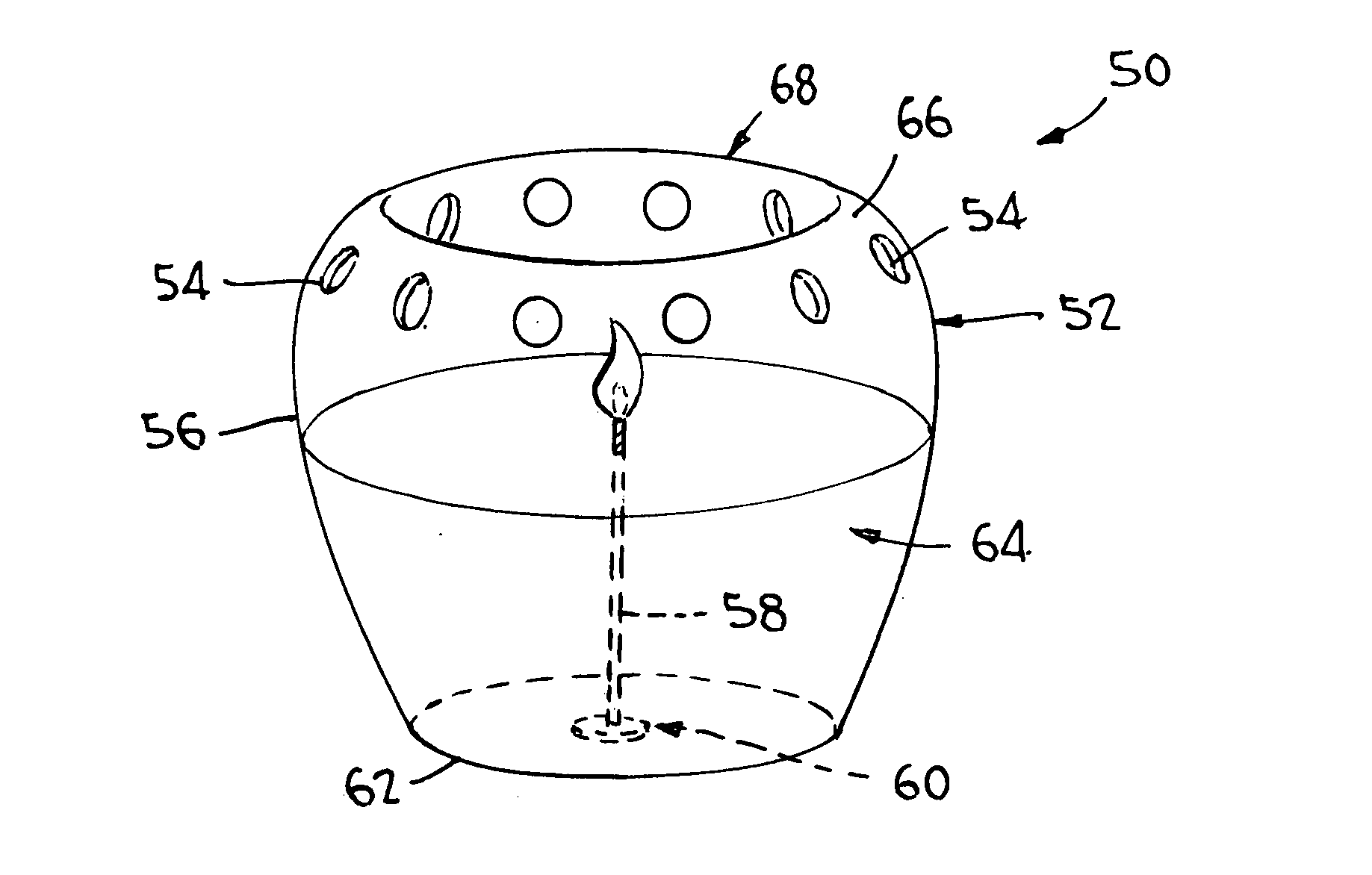

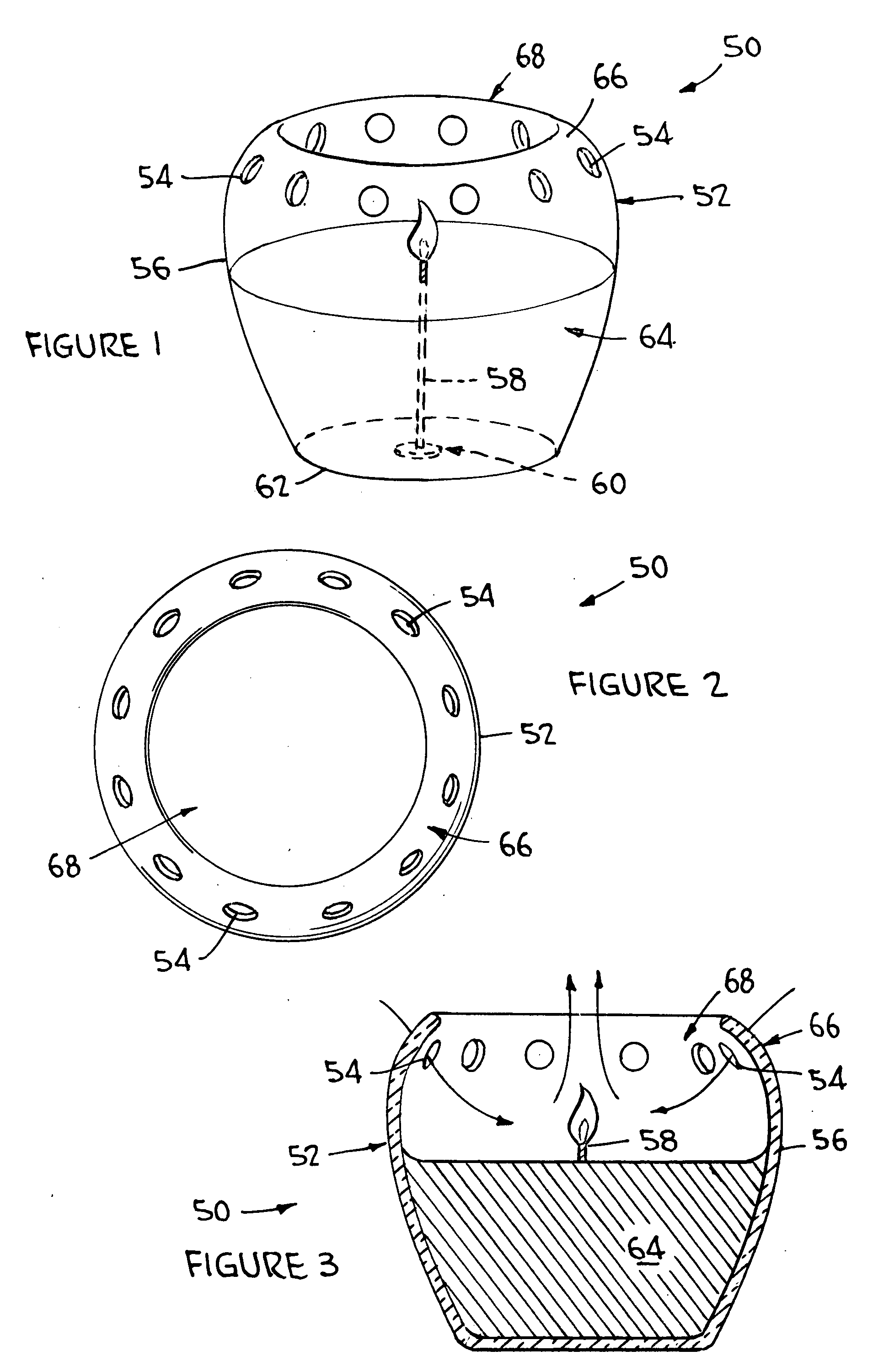

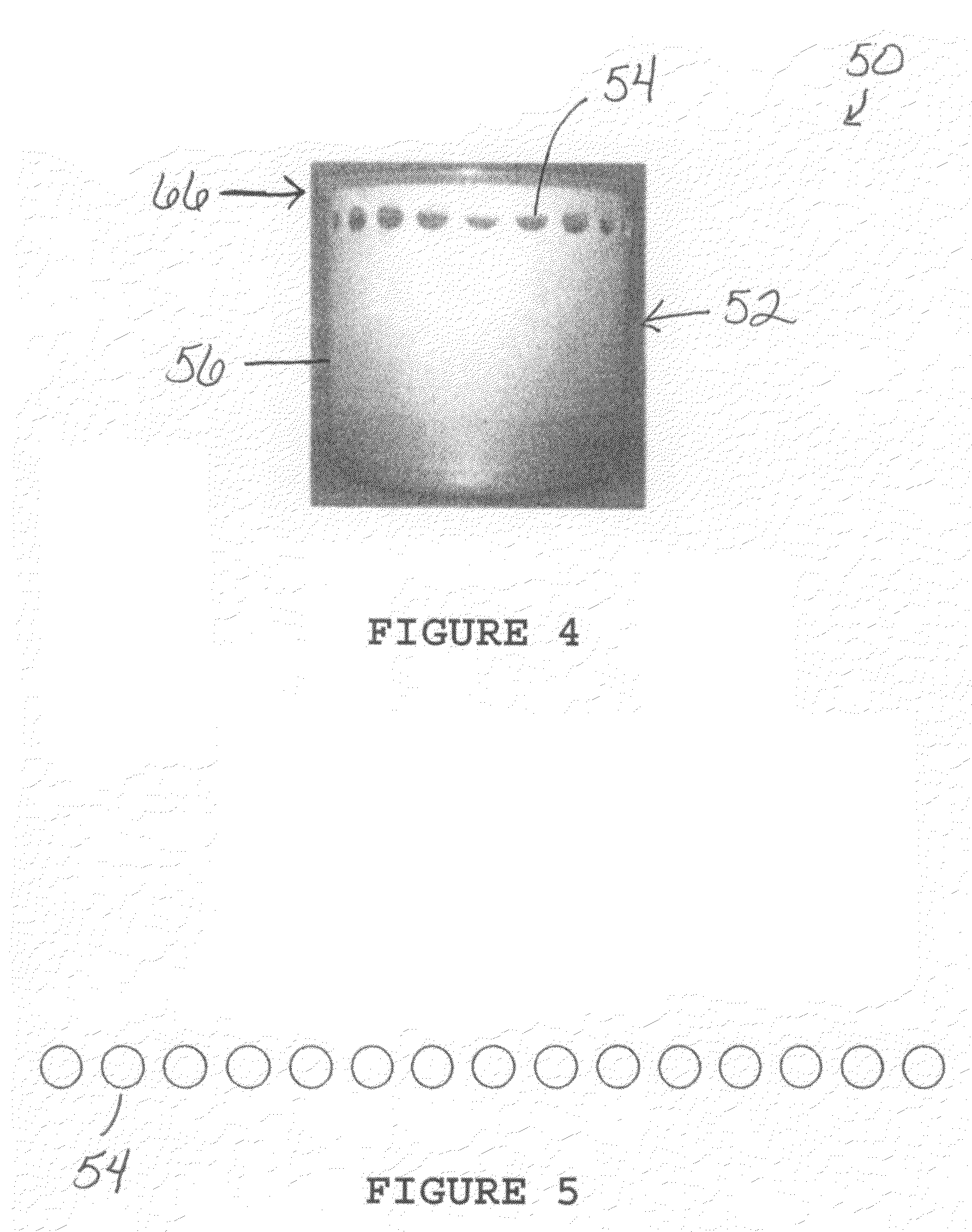

[0055]Referring to FIGS. 1-27, the present invention relates to a non-sooting containerized candle 50. More particularly, the invention relates to candle containers 52 having a pattern of holes 54 in the upper side wall portion 56 of the container 52 for venting the container to provide complete combustion of the candle in the container and to prevent emission of carbon particulates. A clean or non-sooting candle, whether scented or unscented, has controlled fuel consumption and complete combustion. When combustion is not complete, carbon particulates, along with water and carbon dioxide, which are the products of complete combustion, are also generated or emitted and deposited as soot on the container wall and / or a surface in the surrounding environment. This generally is an undesirable result of burning a candle for users. The containerized candle of the present invention reduces soot emission and, as such, is a non-sooting candle.

[0056]The containerized candle 50 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com