Combustion initiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

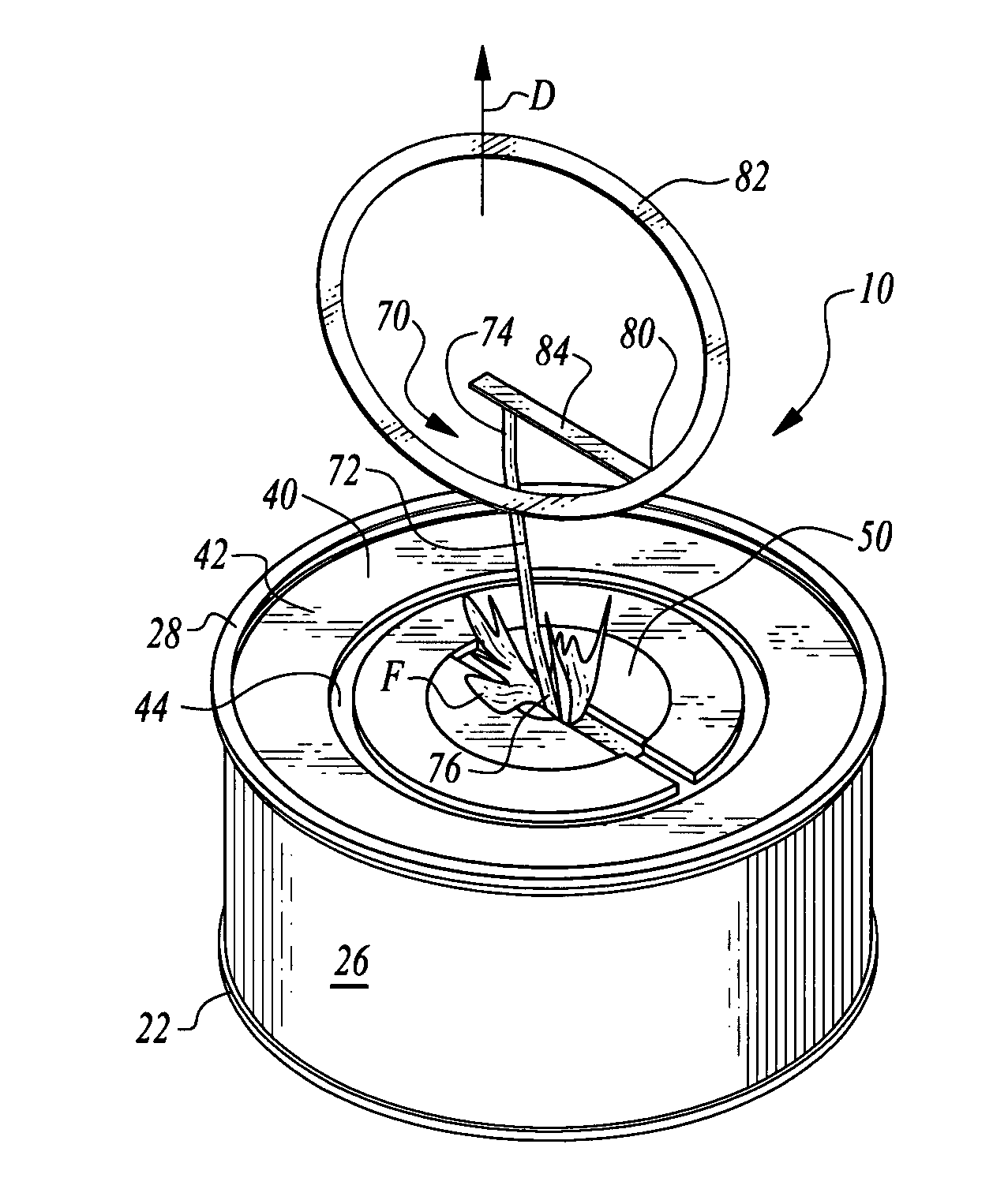

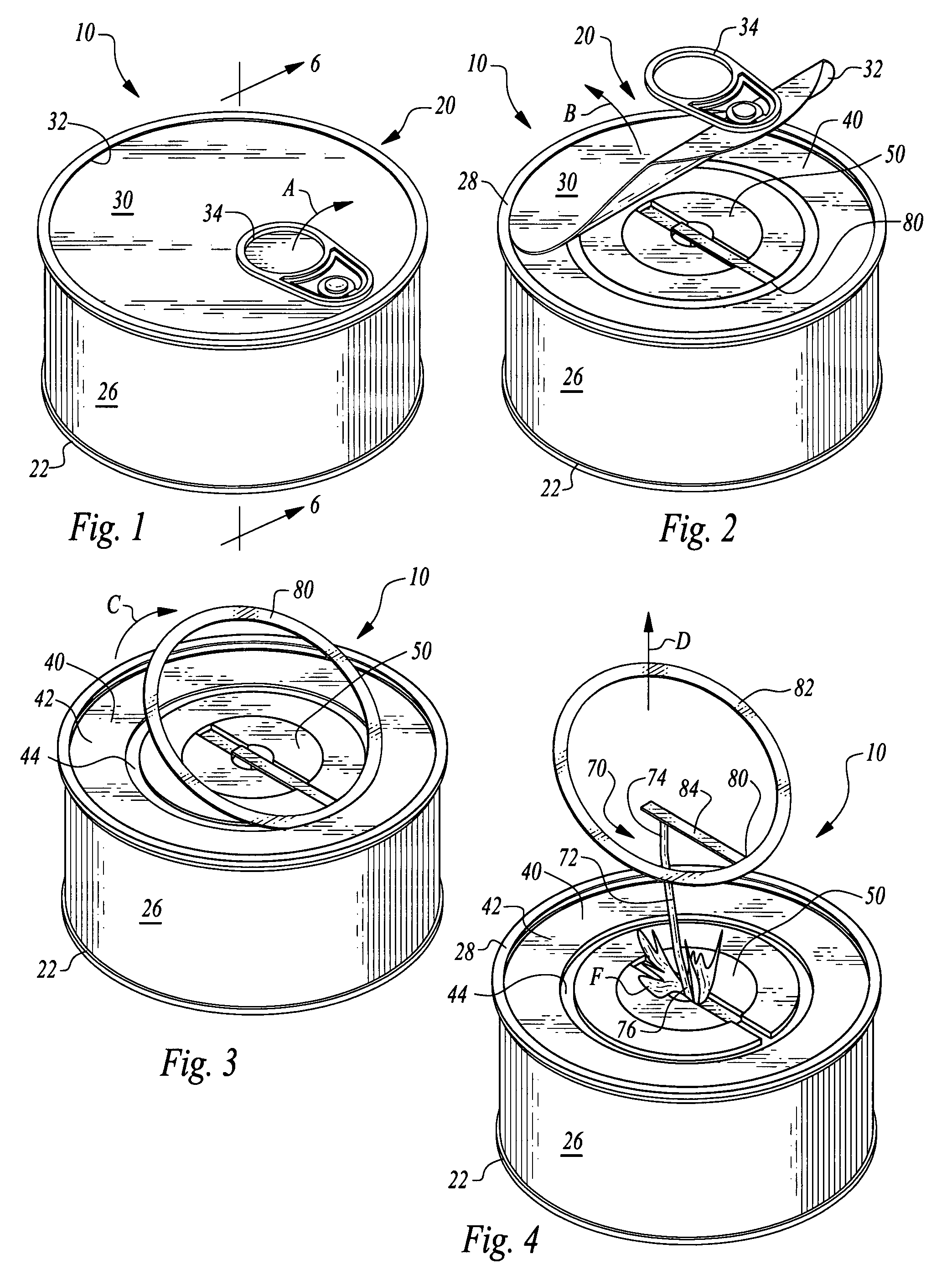

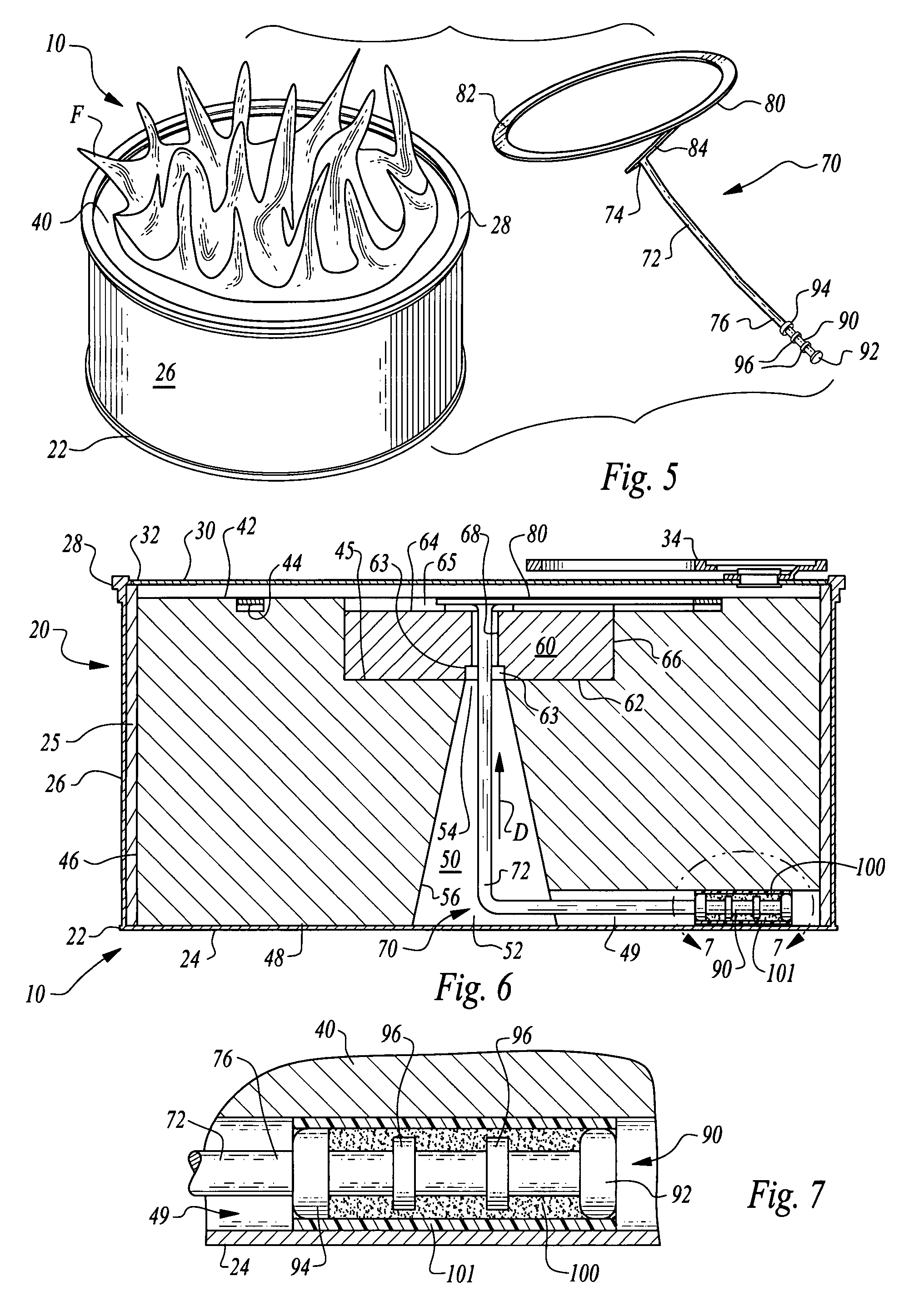

[0031]Referring to the drawings, wherein like reference numerals represent like parts throughout the various drawing figures, reference numeral 10 is directed to a combustion initiator (FIGS. 1-6) according to a preferred embodiment of this invention. The combustion initiator 10 can be utilized to easily initiate combustion of difficult to burn fuels, such as wet wood, placed adjacent to the combustion initiator 10 before activation of the combustion initiator 10. Such activation involves removing a lid 30 from an enclosure 20 containing the combustion initiator 10 and pulling of a pull ring 80 on an igniter train 70 of the combustion initiator 10 until fire F results (FIGS. 4 and 5).

[0032]In essence, and with particular reference to FIGS. 1-6, basic details of the combustion initiator 10 of this invention are described according to the preferred embodiment. The combustion initiator 10 preferably is contained within an enclosure 20 formed of a container 22 and a lid 30 which seals t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com