Load Bearing Bracket for Adjustable Gear Bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

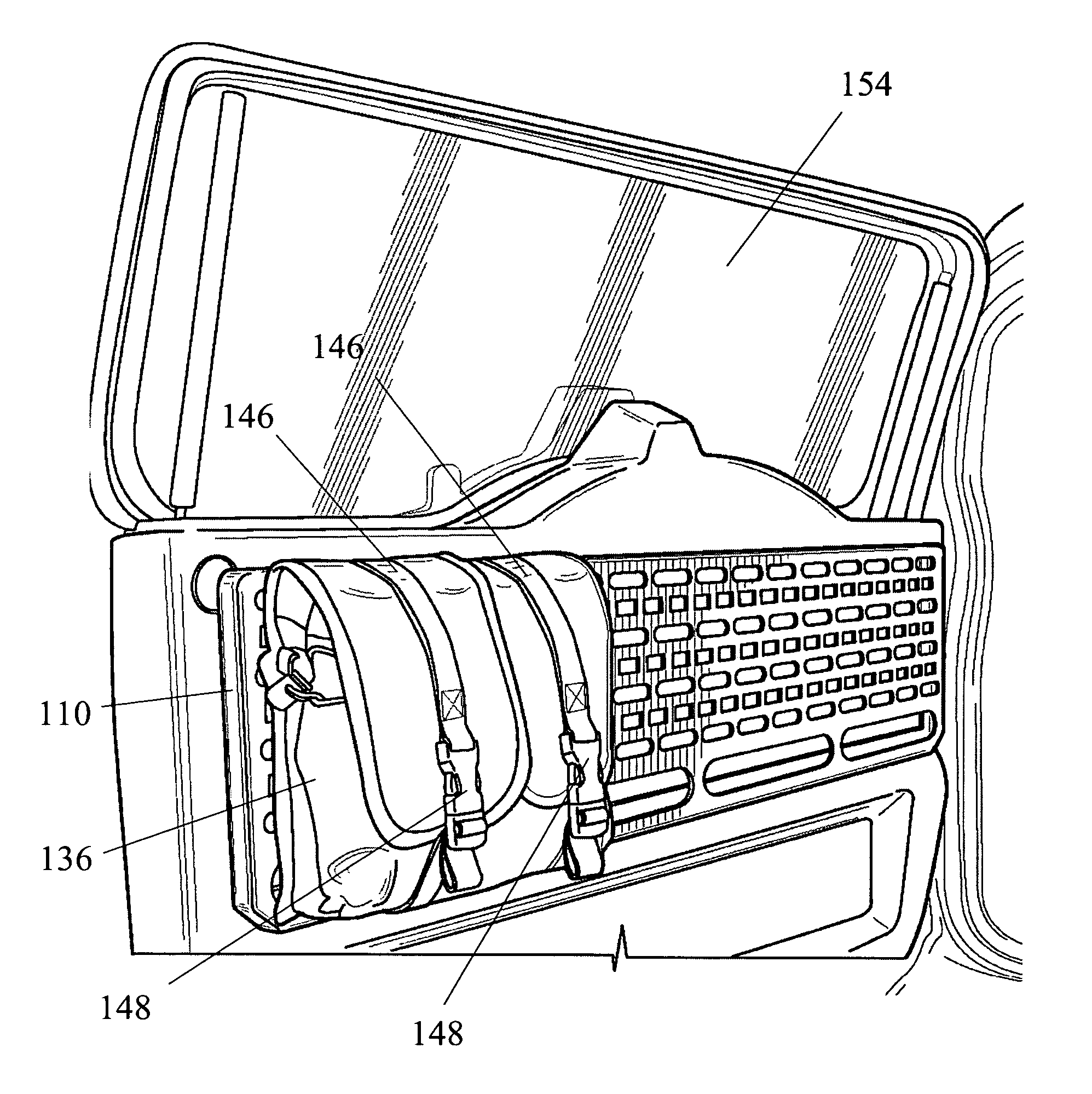

Image

Examples

Embodiment Construction

[0015]In the following detailed description of the invention, reference is made to the drawings in which reference numerals refer to like elements, and which are intended to show by way of illustration specific embodiments in which the invention may be practiced. It is understood that other embodiments may be utilized and that structural changes may be made without departing from the scope and spirit of the invention.

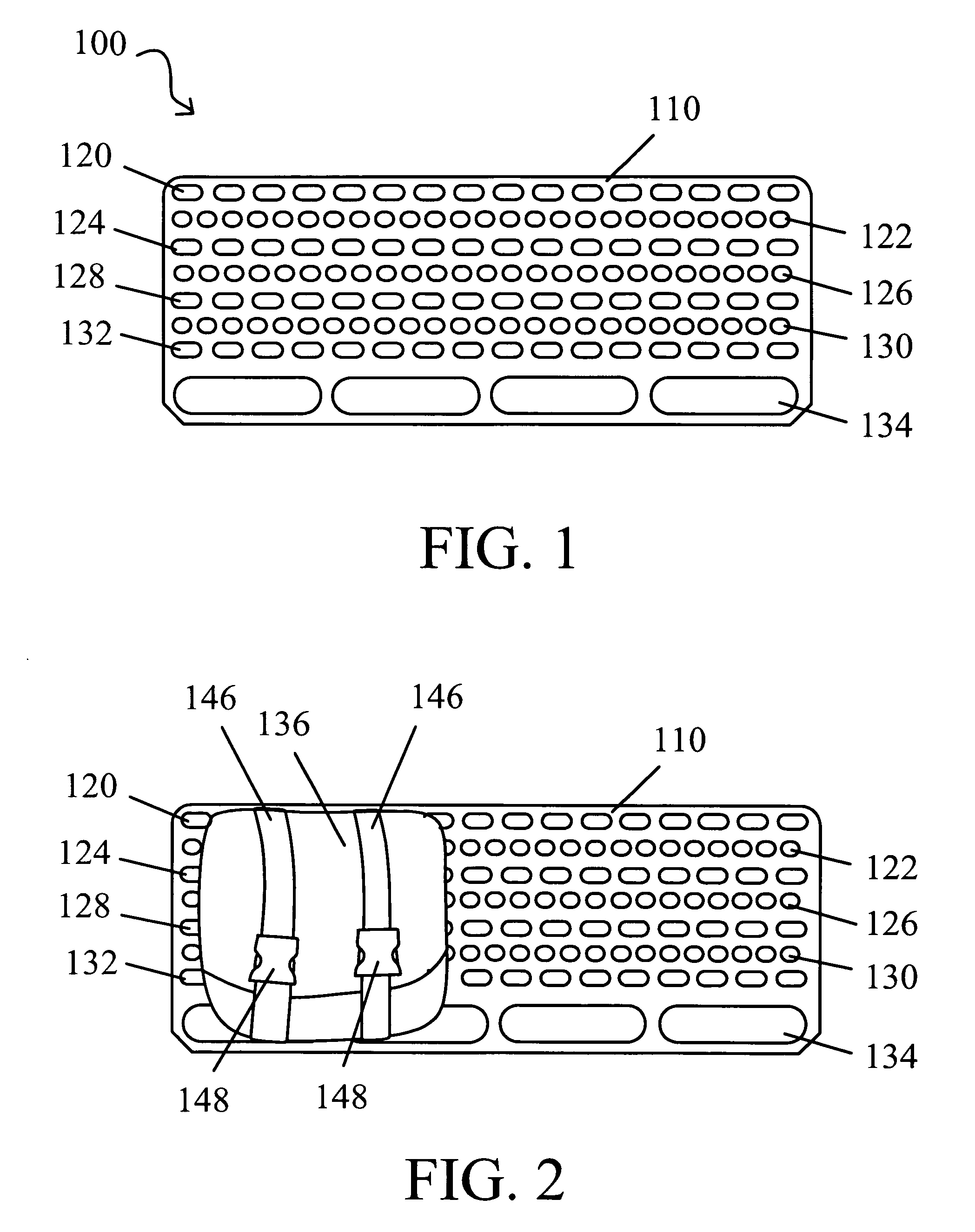

[0016]Referring to FIG. 1, a load bearing bracket for adjustable gear bags 100 comprises a base bracket 110 with a plurality of openings arranged in rows and columns. A row of oval openings 120, 124, 128 and 132 are uniform in size and alternate with rows of smaller openings 122, 126 and 130 respectively. A plurality of large adjustment openings 134 are disposed along a bottom portion of base bracket 110 and allow a user to insert his or her hand therein.

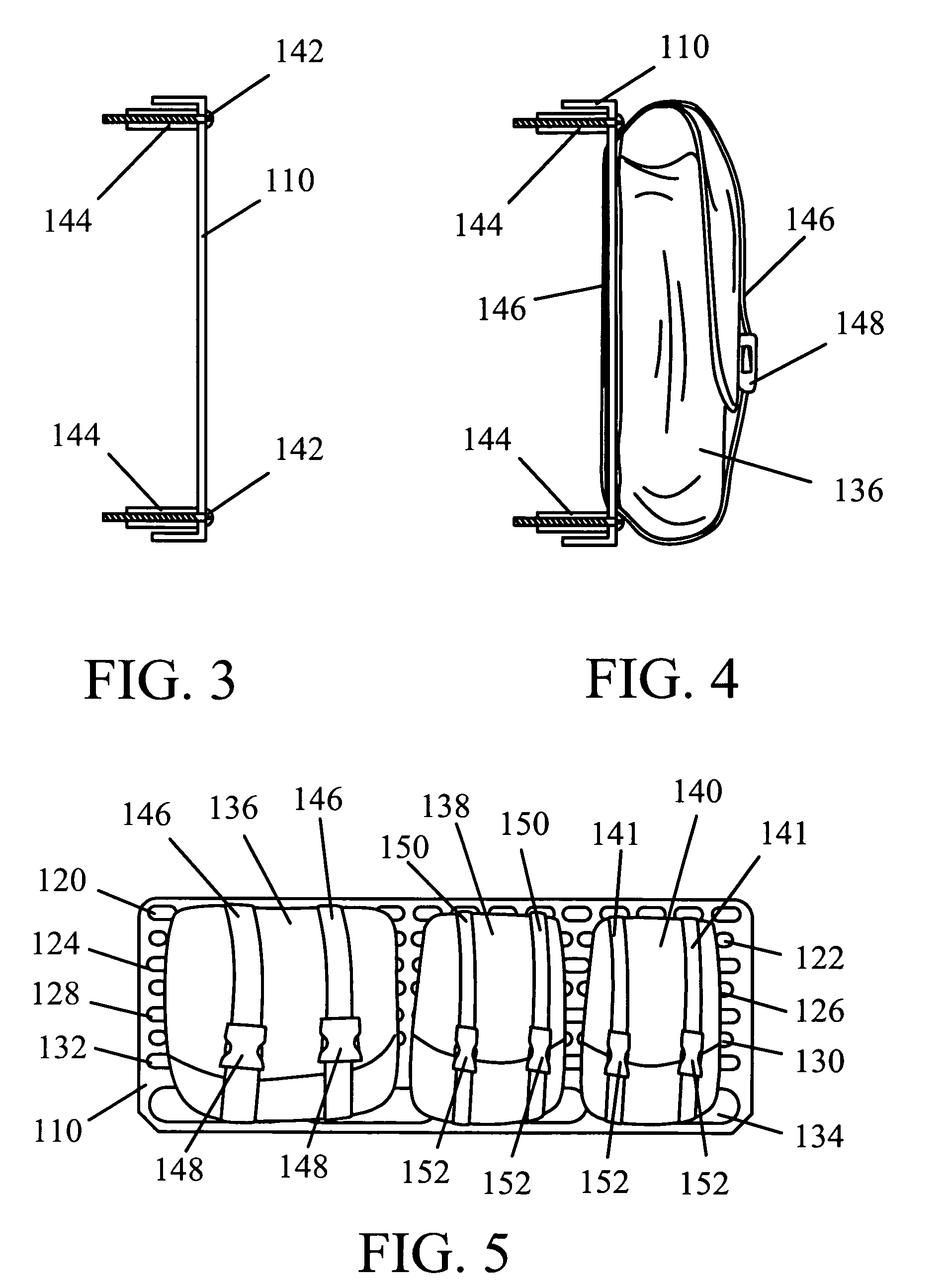

[0017]Referring now to FIGS. 2 through 4, a MOLLE bag 136 is shown attached to base bracket 110 with straps 146 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com