Self-priming electronic metering pump and priming methodology

a self-priming, electronic metering technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of vapor lock, actual damage to the pump, and situation wear on the pump without any work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

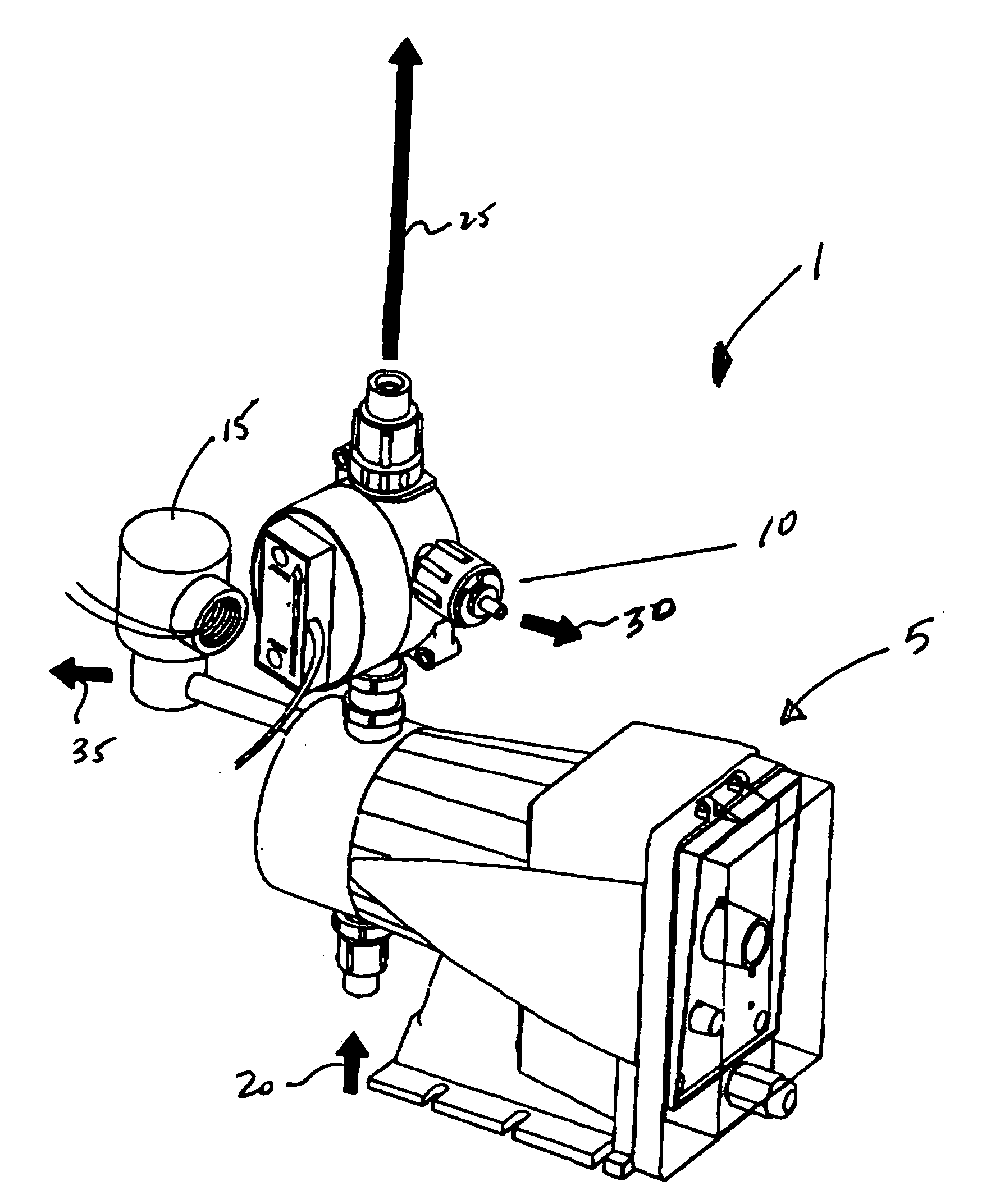

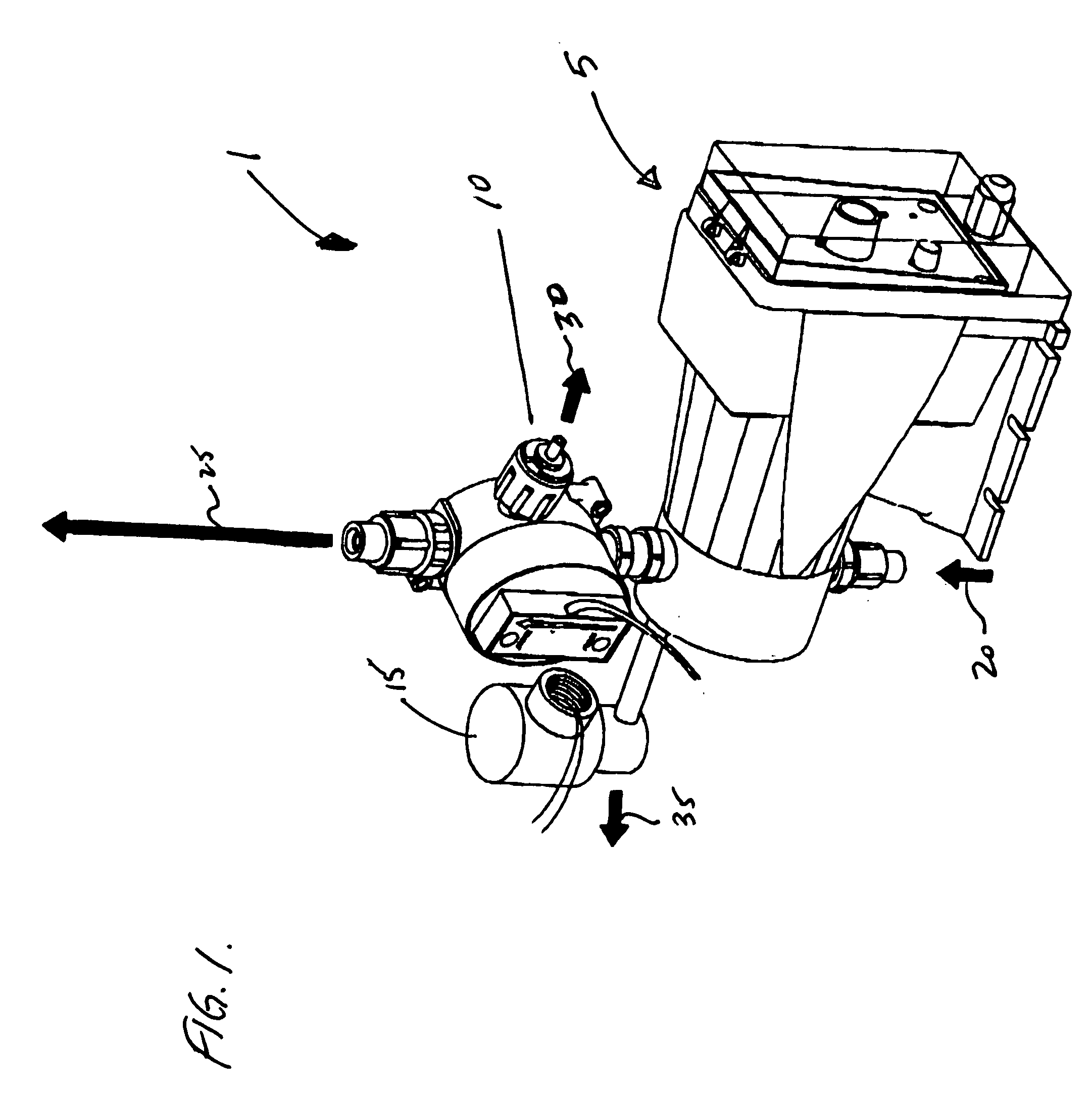

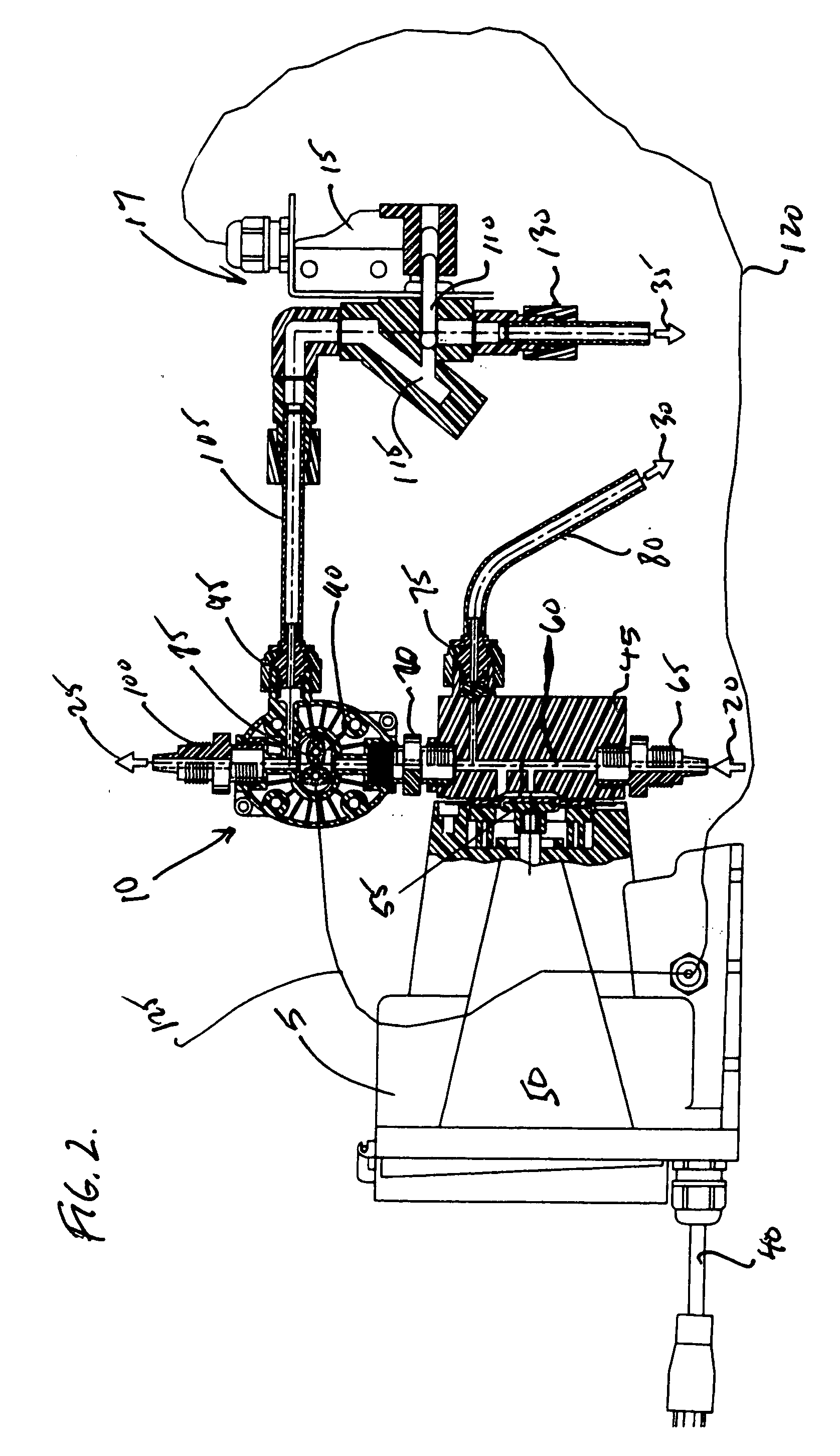

[0019]Referring now to FIG. 1, self priming pump assembly 1 is comprised of a electronic metering pump 5 of a conventional type. Examples of typical pumps are (1) LMI Milton Roy model AA15392SI; (2) Pulsafeeder model LE13Sa-PHC1; and Prominent model g / 4 . . . 0703. Pump 5 includes an electronic motor (not shown) which operates a displaceable element which creates a pressure differential within the pump. A flow sensor module 10 is affixed to pump 5 in fluid communication through a conduit. No specific geometry or arrangement of the fluid circuit is specified and the same is adapted to the particular physical and environmental needs of the application. A solenoid valve 15 is also engaged in fluid communication with pump 5 and / or flow sensor 10 to selectively provide an alternative fluid flow path upon the activation of solenoid valve 15 as part of the self priming functionality described more fully herein. Under normal operating conditions, pump inlet fluid flow 20 is drawn into pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com