Slider for slide fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

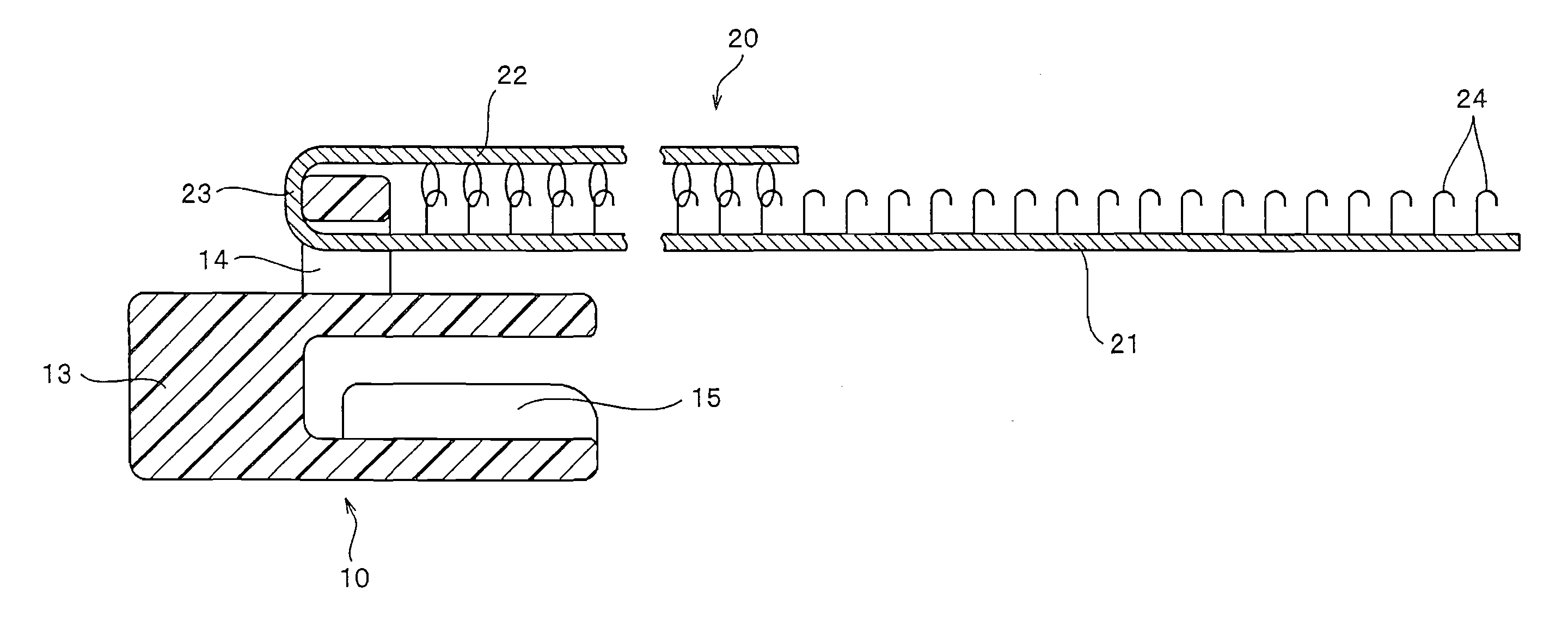

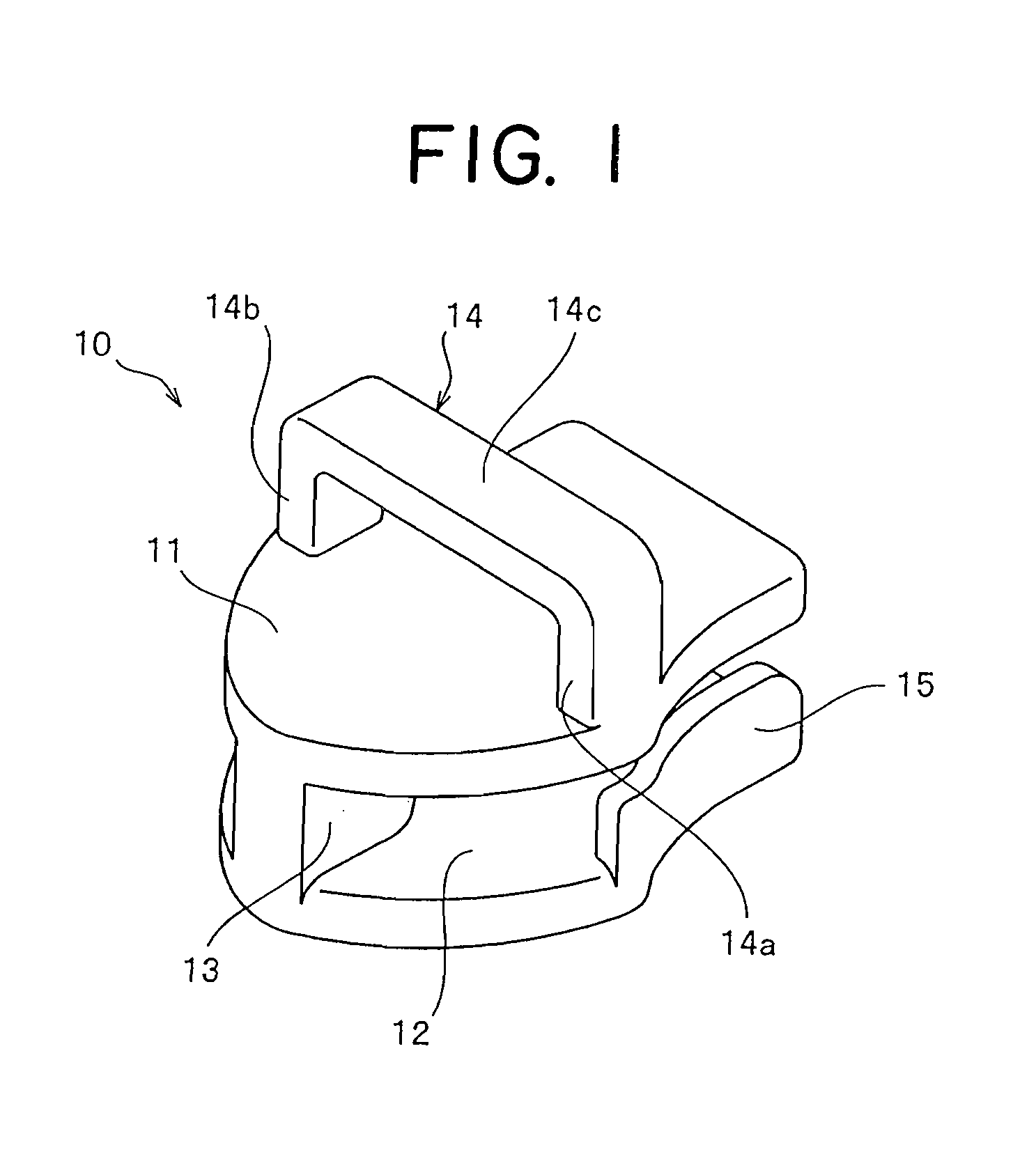

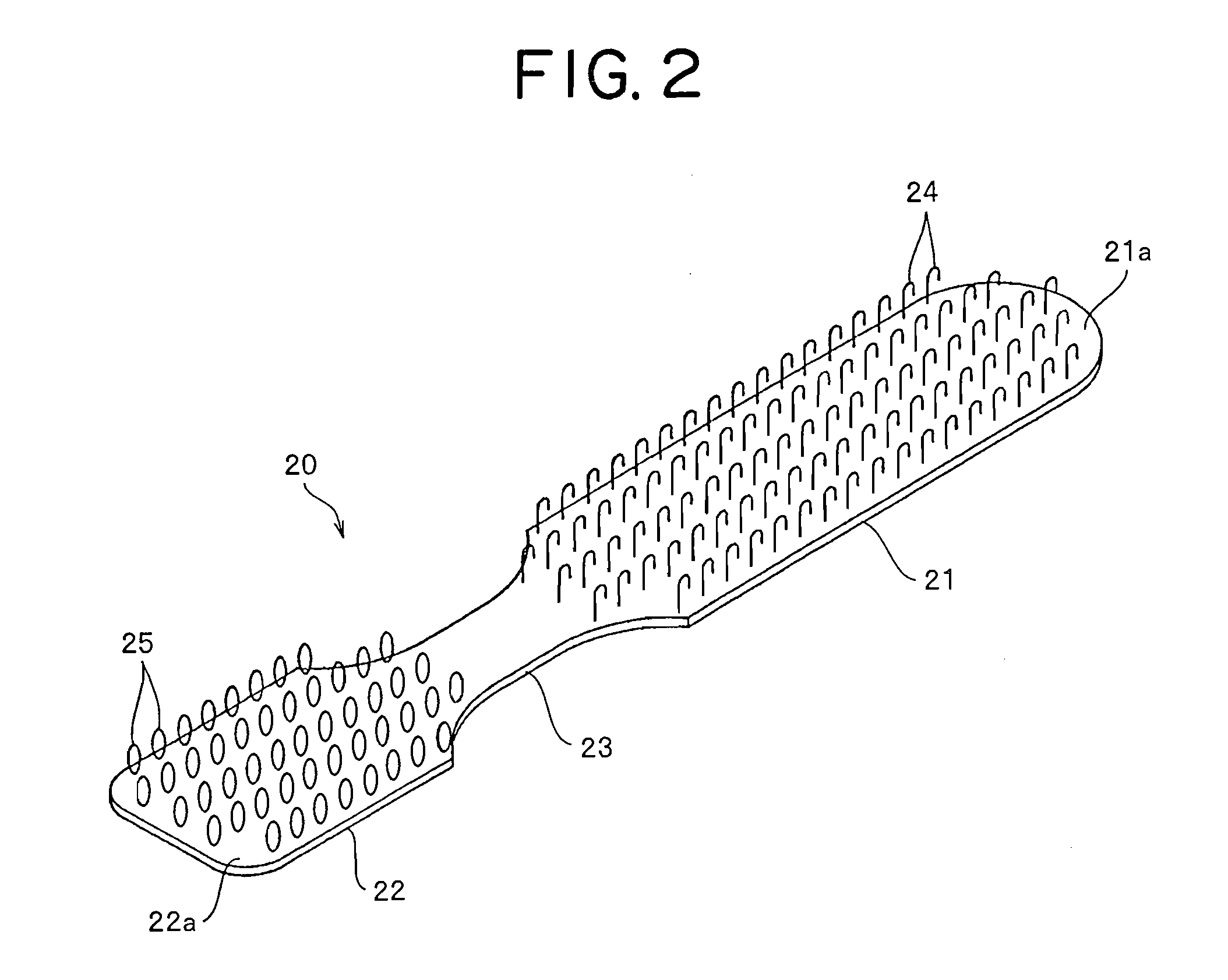

[0058]FIGS. 1 to 3 show a slider for a slide fastener according to a first embodiment of the present invention. FIG. 1 is a perspective view showing a slider body of the slider, and FIG. 2 is a perspective view showing a pull tab of the slider. FIG. 3 is a sectional view showing the section in the back-forth direction of the slider.

[0059]In the description of each embodiment, the back-forth direction of the slider is a direction parallel to the sliding direction of the slider. In the slide fastener, a direction in which the slider is slid to couple right and left elements is assumed to be forward while a direction in which the slider is slid to separate the right and left elements is assumed to be backward. The right and left direction of the slider is a direction at right angle to the back-forth direction of the slider and parallel to the fastener tape plane when the slide fastener is constructed, and the up-down direction of the slider is the same direction as the front surface to...

second embodiment

[0086]Next, a slider for a slide fastener according to a second embodiment of the present invention will be described. FIG. 9 is a side view schematically showing the slider for a slide fastener according to the second embodiment. In the second embodiment and third to fifth embodiments described later, like reference numerals are attached to components and member having the same structure as the first embodiment, and description thereof is omitted.

[0087]A slider 41 of the second embodiment shown in FIG. 9 has a slider body 10 and a pull tab 42. The slider body 10 has the same configuration as the first embodiment. On the other hand, the pull tab 42 of the second embodiment is formed of a woven narrow thin belt-like body. The pull tab 42 has first and second pull tab main body portions 43, 44 each having the same length disposed in the back-forth direction of the slider and a folding portion 45 for connecting the pull tab main body portions 43 and 44.

[0088]The first and second pull t...

third embodiment

[0093]Subsequently, a slider for a slide fastener according to a third embodiment of the present invention will be described. FIG. 10 is a side view schematically showing the slider for a slide fastener of the third embodiment.

[0094]A slider 46 shown in FIG. 10 includes a slider body 10′ and a pull tab 47. In this slider body 10′, the shape of a pull tab attaching post 14′ is changed with respect to the slider body 10 of the first and second embodiments; a bridge portion 14c′ stretched between right and left leg portions 14a′ and 14b′ is formed cylindrically; and a pull tab insertion slit is provided in a substantially central portion of the bridge portion 14c′. In the meantime, other configuration than the pull tab attaching post 14′ of the slider body 10′ is the same as the slider body 10 of the first and second embodiments.

[0095]The pull tab 47 is formed by molding a synthetic resin. The pull tab 47 includes a pull tab main body portion 48 disposed in the back-forth direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com