Flexible Exhaust Pipe Coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

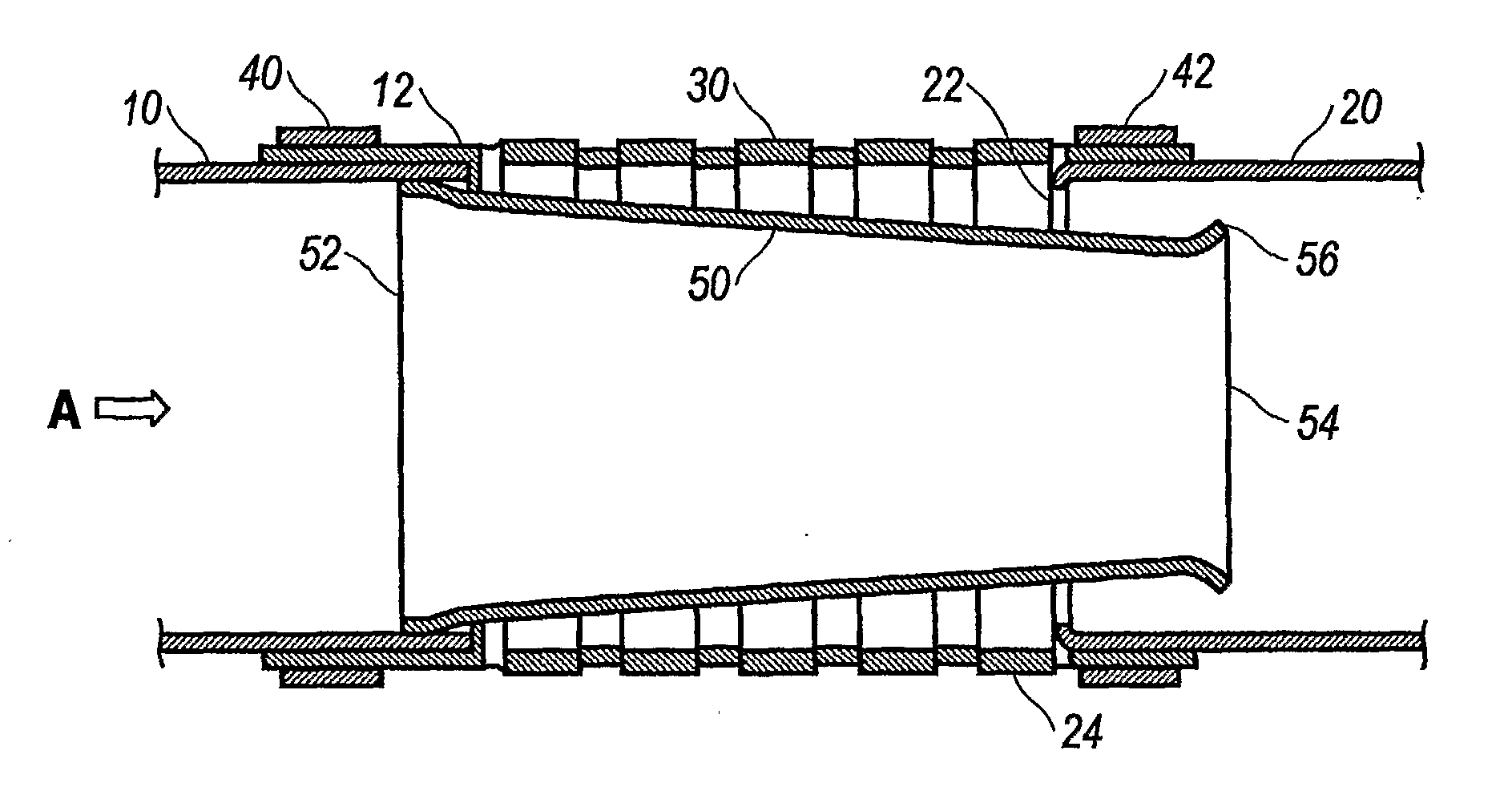

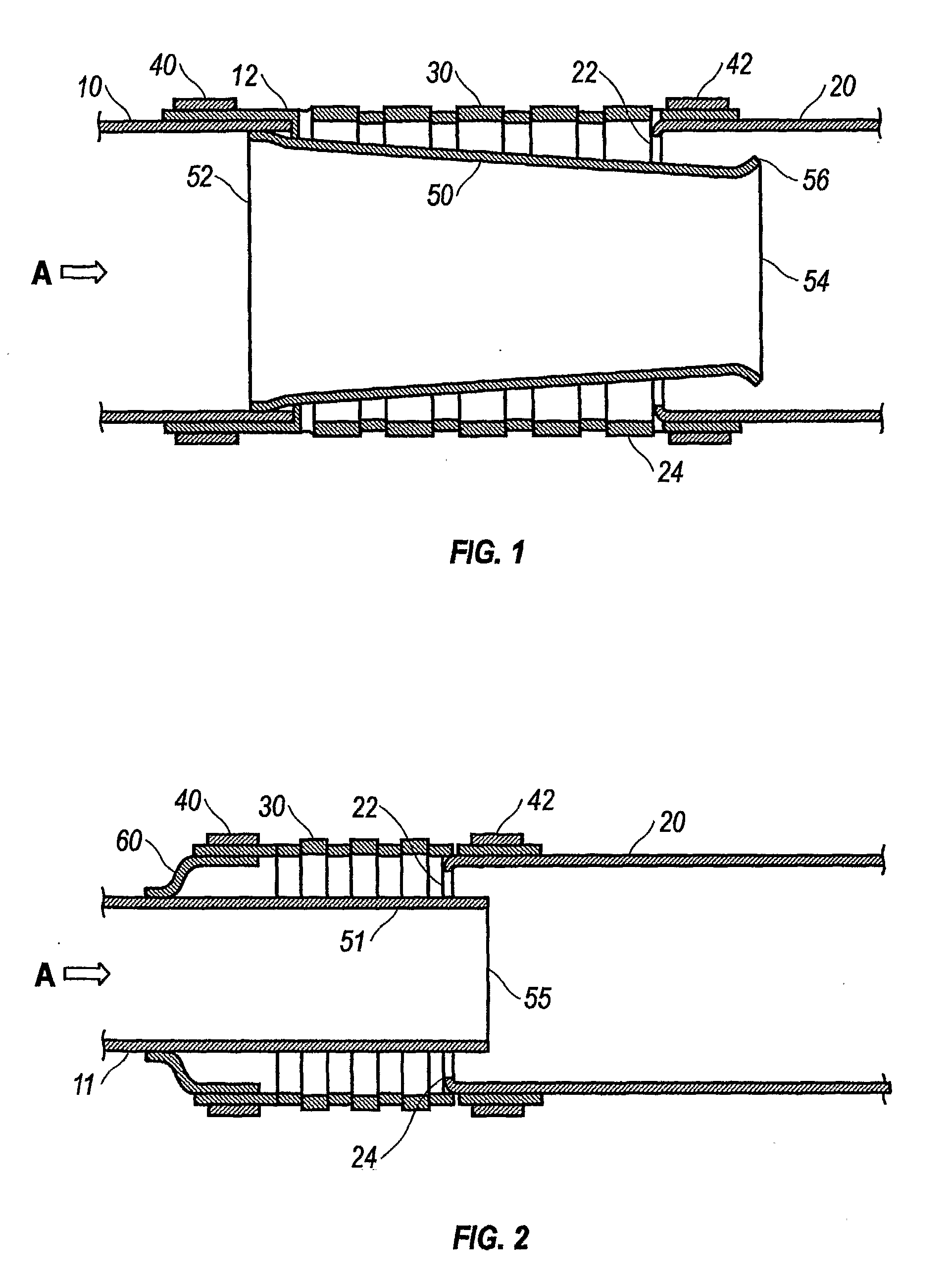

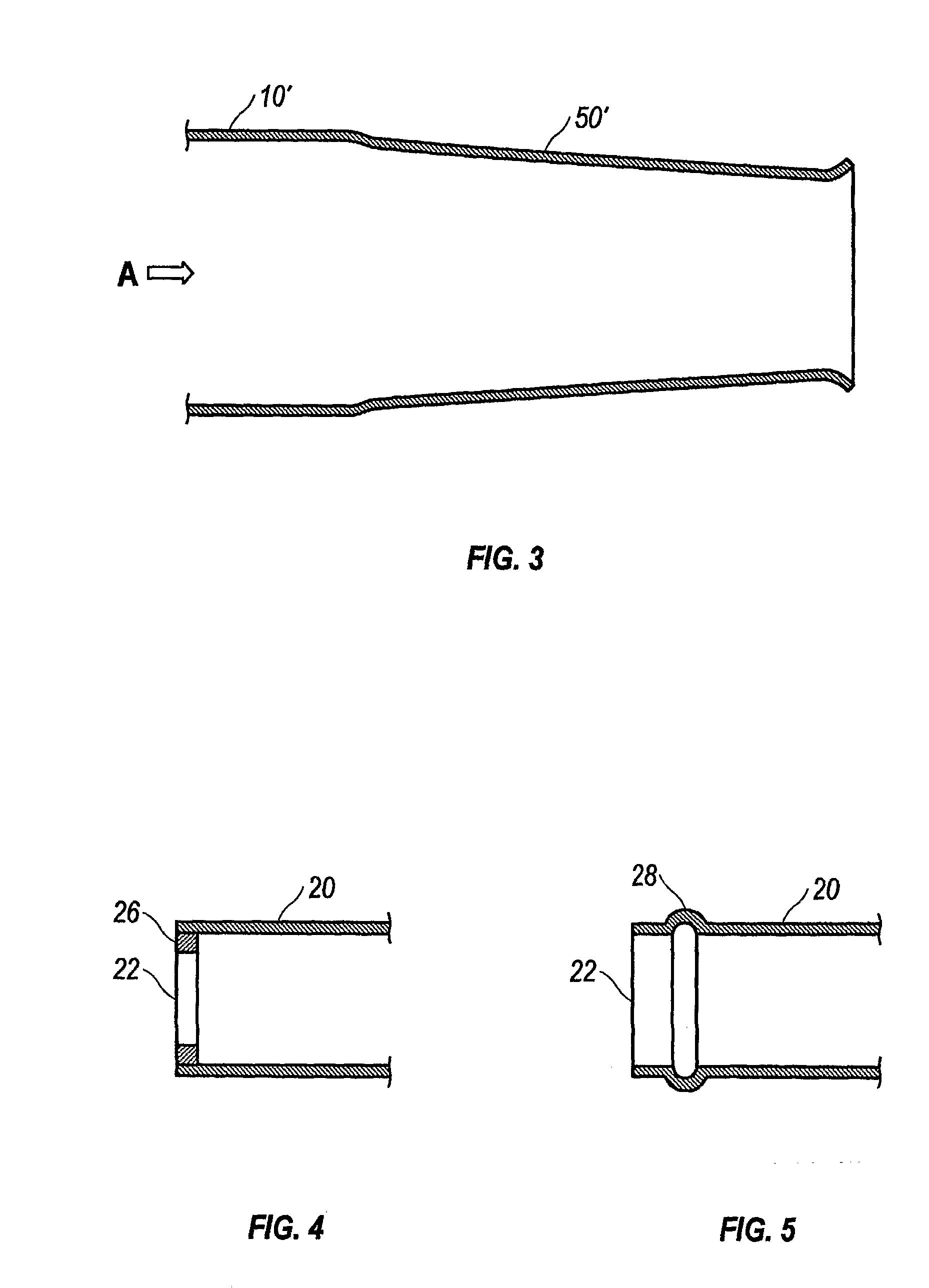

[0019]FIG. 1 shows a longitudinal sectional view of an exhaust pipe coupling device in accordance with a first embodiment of the invention. The device connects an upstream exhaust pipe 10 with a downstream exhaust pipe 20. The normal flow direction of exhaust gas is shown by arrow A. In addition to carrying gas combustion products, truck exhaust systems are or may in the future be called on to carry liquid material to treat the combustion products or to clean or regenerate exhaust after-treatment devices, such as diesel particulate filters, oxidizers, or catalyzers. The liquid material may be as a condensate or atomized form, and may include automotive or diesel fuel, urea, ammonia, or some other combustive, oxidizing or catalyzing agent. The device according to invention assures that liquid material passes the joint areas in the exhaust piping without leakage.

[0020]A flexible sleeve 30 receives the outlet end 12 of the upstream pipe 10 and the inlet end 22 of the downstream pipe 20...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap