Wide-range float type flow sensor

A flow sensor, float-type technology, applied in the field of wide-range float-type flow sensor devices, to achieve the effect of simple structure, low cost, and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

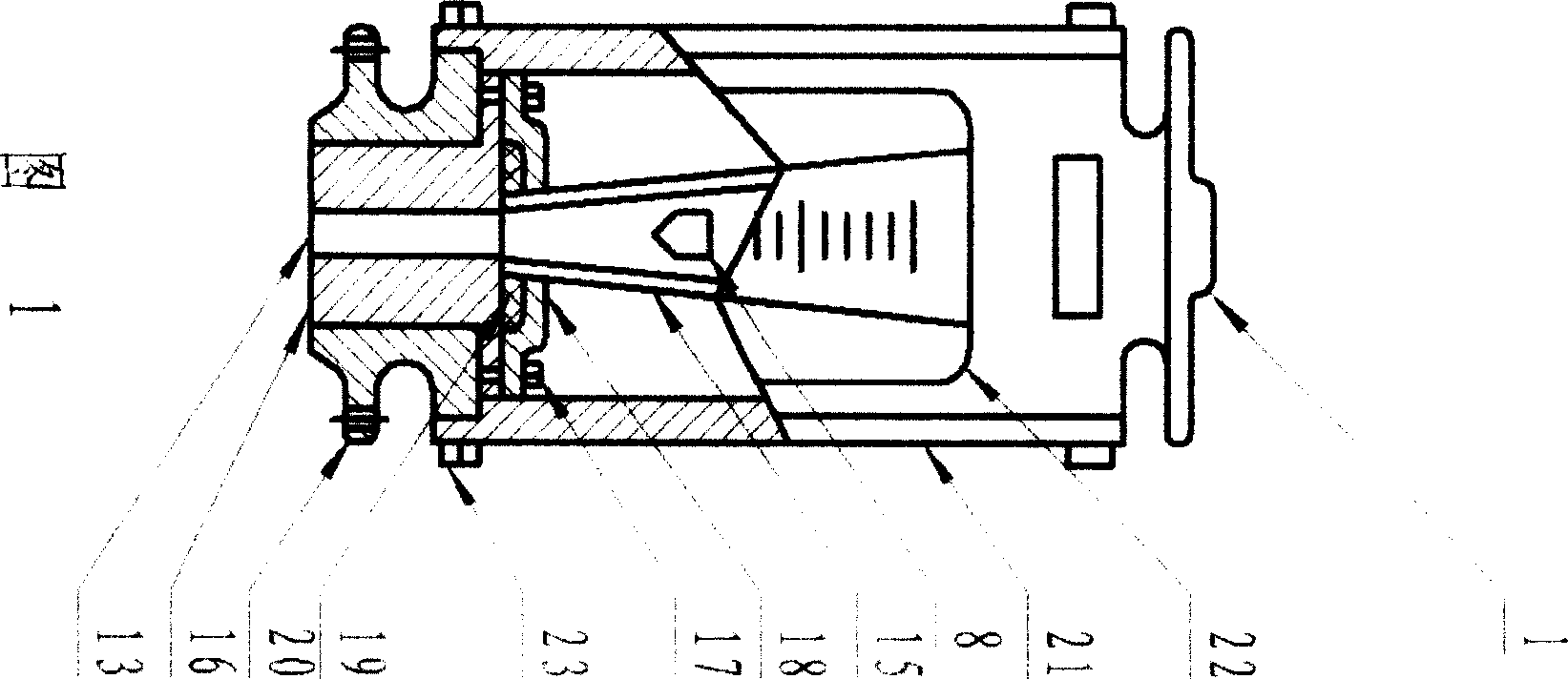

[0013] In FIG. 1 : the float 8 is placed in the conical tube 15 , the conical tube 15 is combined with the insert 16 , and the compression cover 18 together with the sealing ring 19 is fixed on the base 20 by the screw 17 . The support plate 21 and the casing 22 are connected to the base 20 by screws 23 .

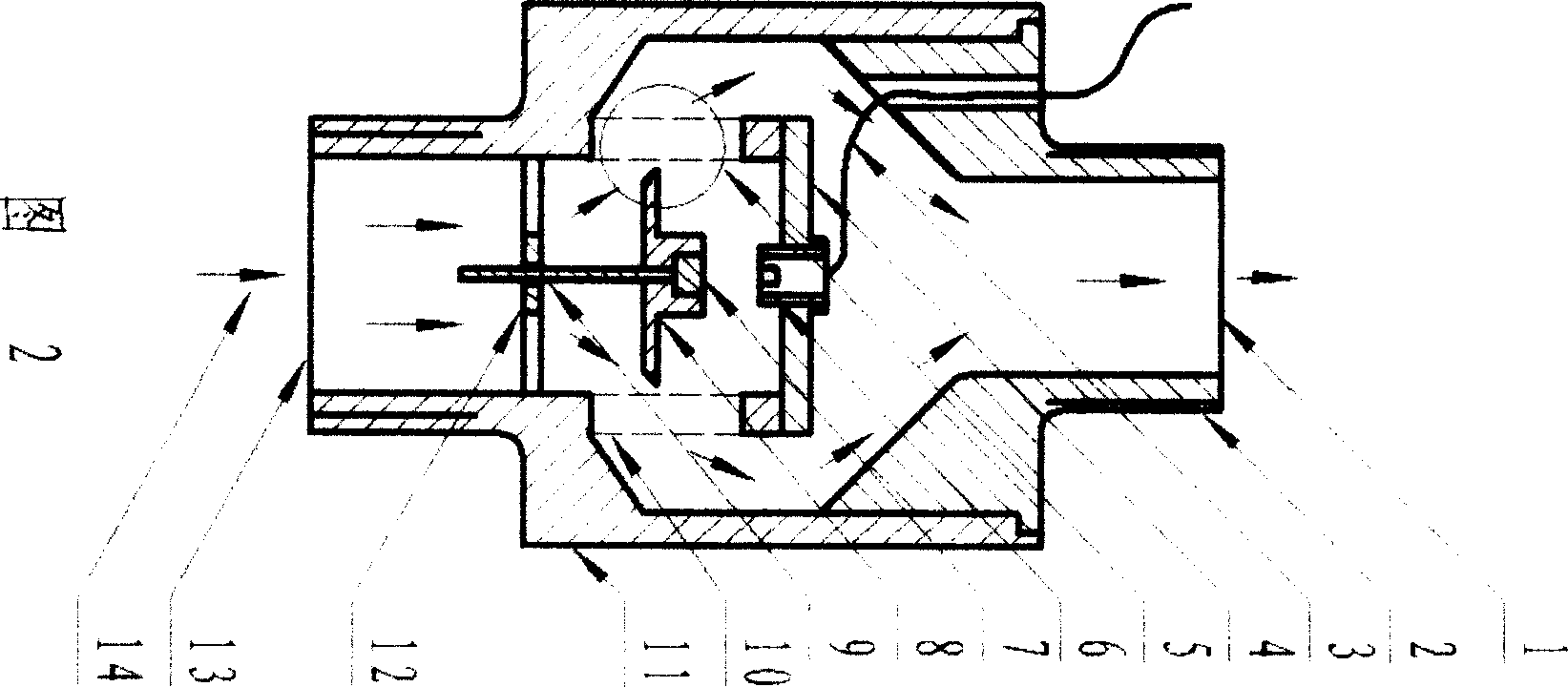

[0014] In Fig. 2: the float guide tube 10 is connected with the sensor lower housing 11, the guide bracket 12 is connected with the inner wall of the guide tube 10, the guide rod 9 is fixedly connected with the center position below the float 8, and the magnet 7 is fixed above the float 8 The center position, and corresponds to the center of the Hall probe 6. When assembling, the float should move up and down flexibly. During manufacture, the upper and lower housings 2 and 11 and the draft tube 9 are circular, the float 8 is a circular sheet, and the guide rod 9 is made of stainless steel material. Probe Hall SS495 market procurement parts. Assemble in the order of insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com