Cartridge filters for gas filtration in gas turbines

A gas turbine and filter technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of design parameters, materials, and structures that are not fully suitable for gas turbine terminal filters, and achieves easy disassembly and cleaning, high filtration accuracy, Guarantee the effect of filtering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

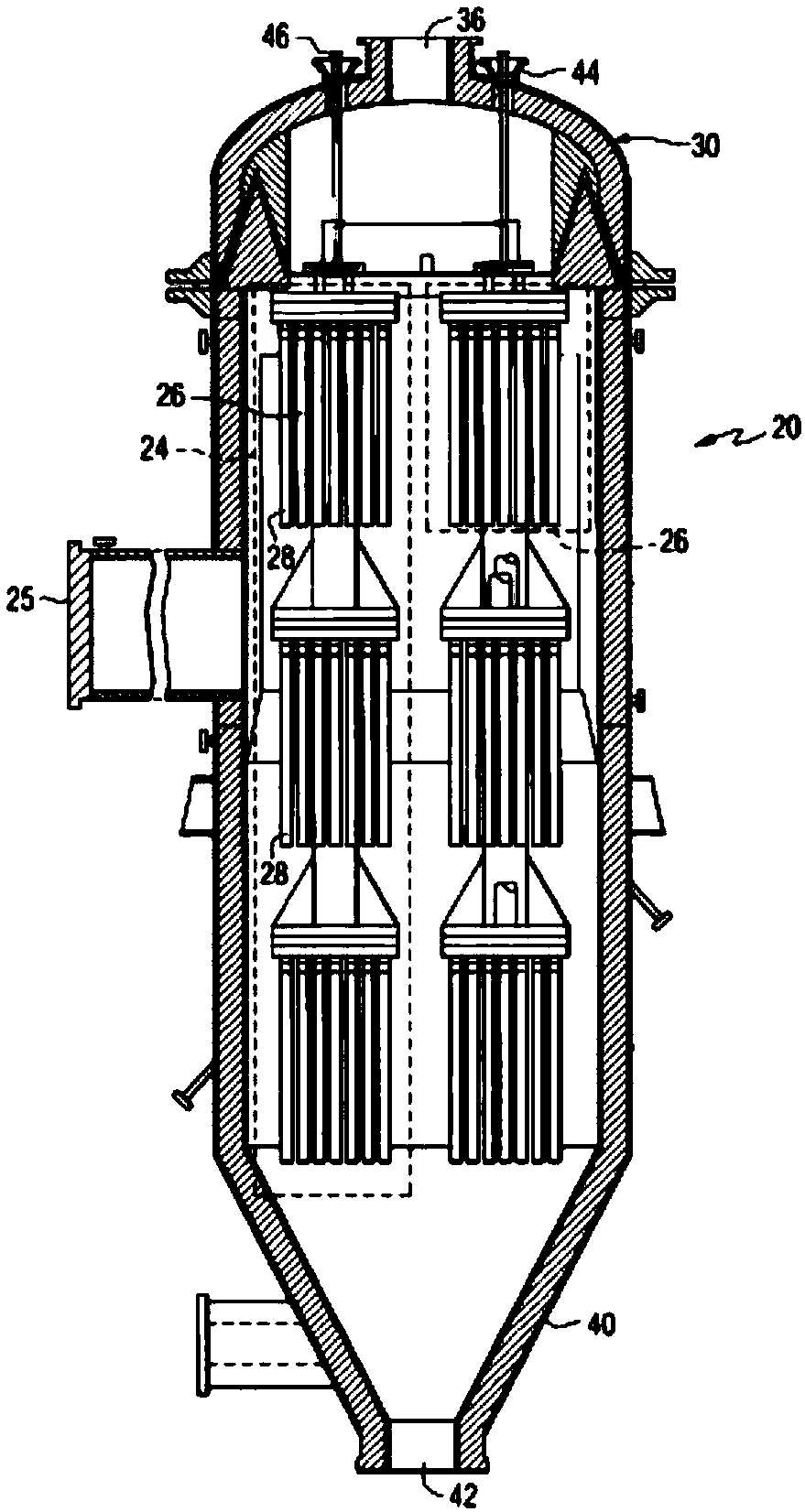

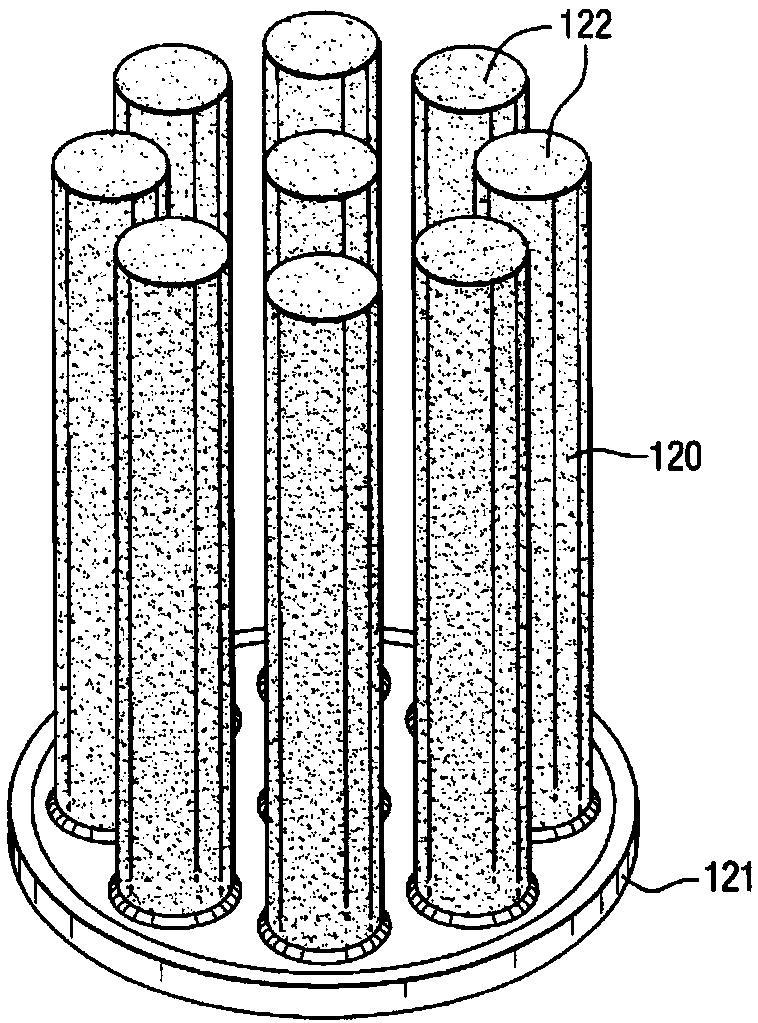

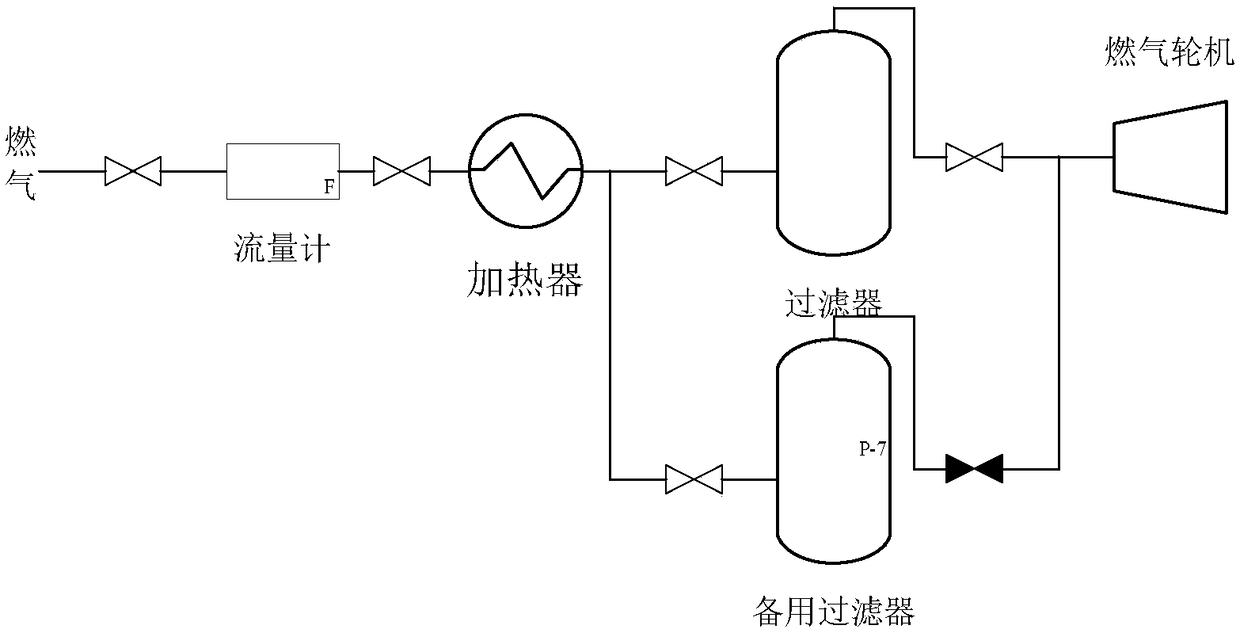

[0033] An embodiment of the present invention, such as image 3 As shown, a high-temperature gas filter is installed near the gas inlet of the gas turbine. The gas filter is connected to the gas inlet of the gas turbine in a double-parallel manner. Stop for maintenance or clean the filter element.

[0034] Filter design parameters in this embodiment: the maximum flow rate of natural gas is about 79000kg / h (at 3.5Mpa, 200°C), the minimum value is about 2566kg / h (at 3.7Mpa, 15°C), and the normal value is about 66000kg / h h (at 3.5Mpa, 200°C), design pressure 5Mpa, design temperature 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com