Connector

a technology of connecting rods and connecting rods, applied in the direction of pipe connection arrangements, roof coverings, branching pipes, etc., can solve the problems of system inoperable, unsatisfactory results, and potential to destroy animal and plant li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

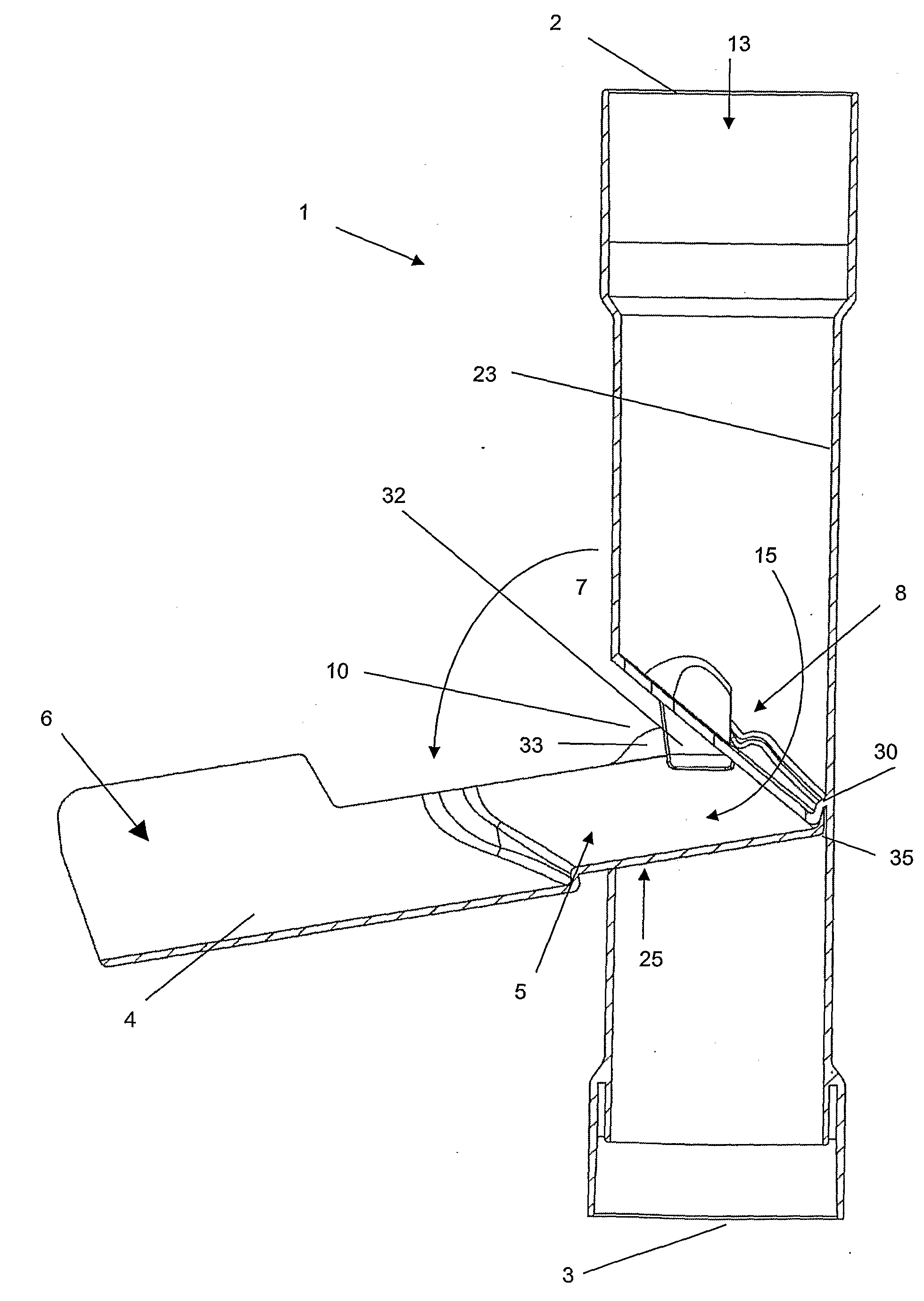

[0060]With respect to FIG. 1, there is a connector in the form of a down-pipe connector generally indicated by arrow 1 in a non by-pass configuration. The down-pipe connector 1 is substantially tubular in nature.

[0061]The down-pipe connector 1 has an inlet 2 and an outlet 3. The connector 1 has a by-pass portion in the form of a flap 4, which lies substantially parallel with the side of the down-pipe connector 1.

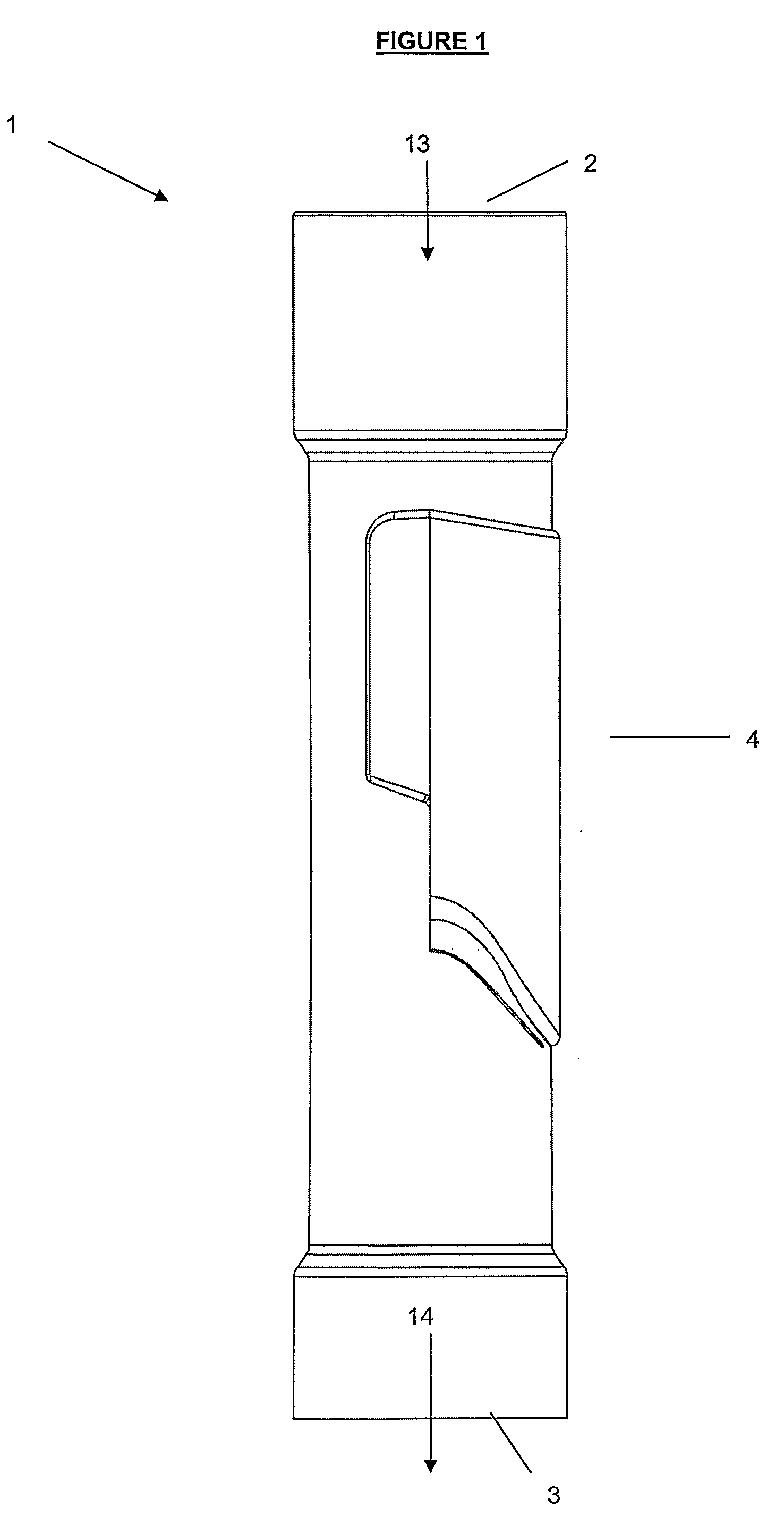

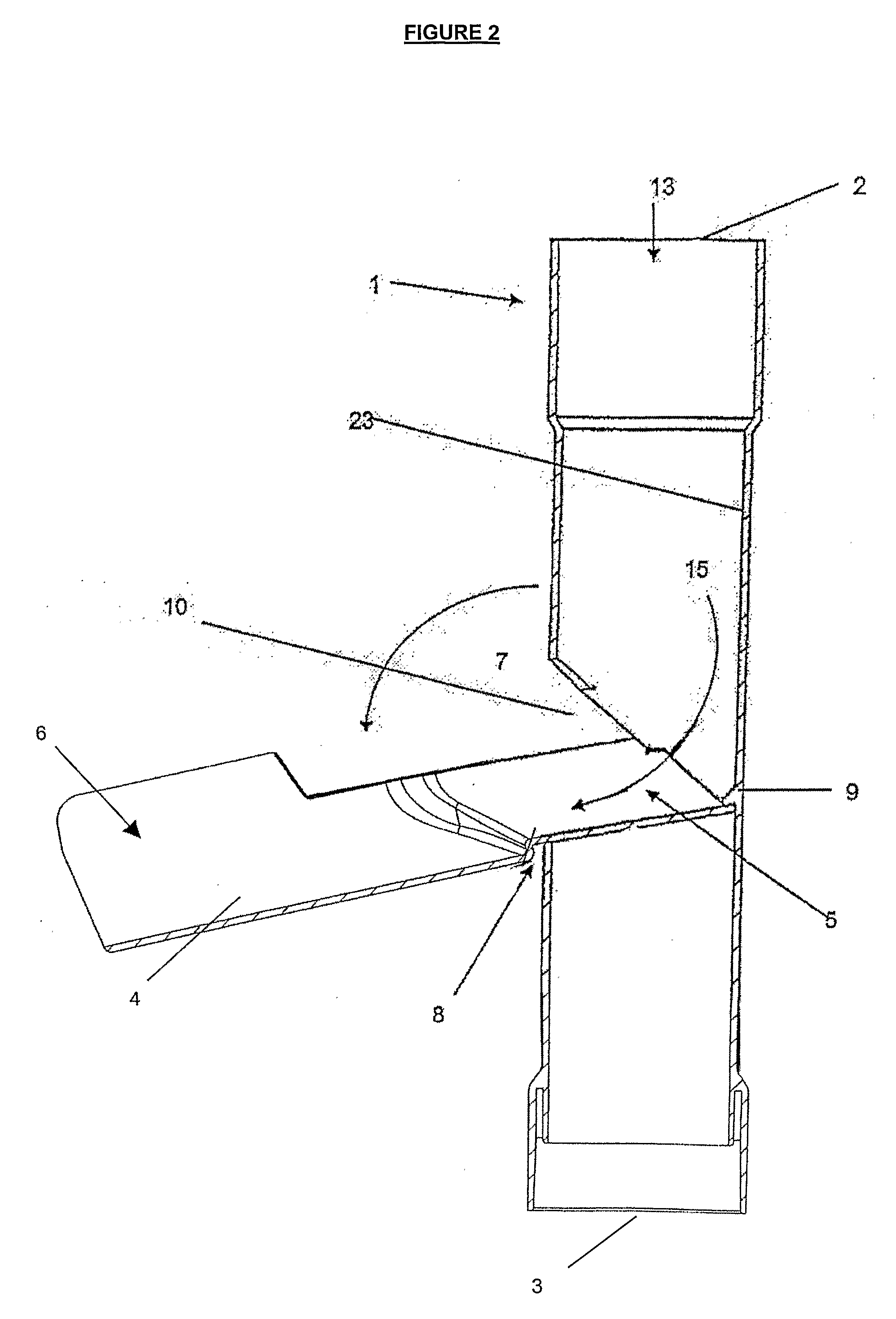

[0062]With respect to FIG. 2, there is a down-pipe connector 1 in by-pass configuration. The flap 4 has an internal portion 5 and external portion 6.

[0063]In this embodiment, the flap 4 has been moved via pivoting in the direction indicated by arrow 7 and pivots about a pivot point generally indicated by arrow 8. This causes the internal portion 5 to abut with a region of overlap in the form of a protruding lip 9 on the internal surface 23 of the connector 1. Moving the flap 4 exposes the by-pass outlet 10 on side of the down-pipe connector 1.

[0064]When the down-pipe connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal diameters | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com