Shoe suction press roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

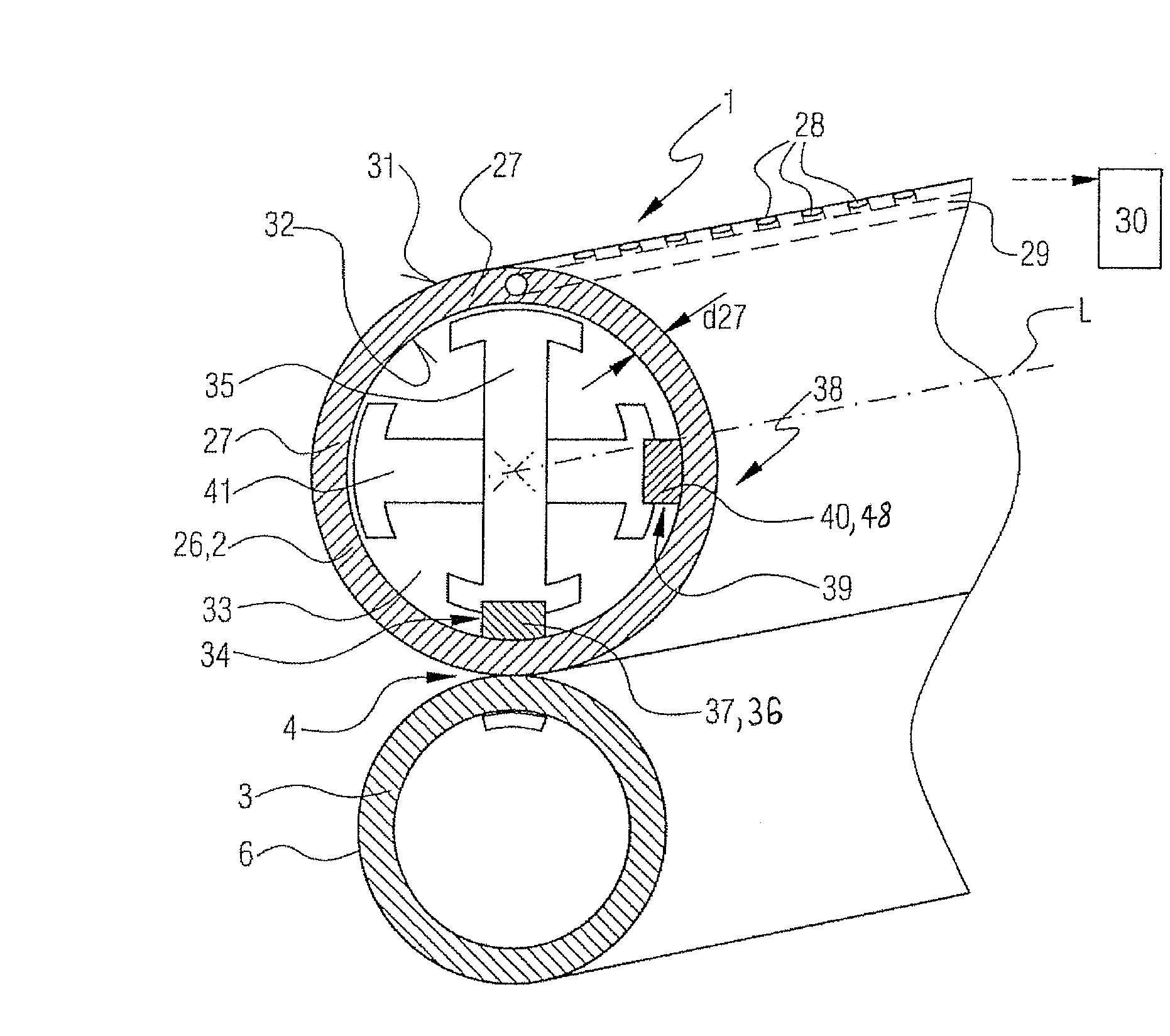

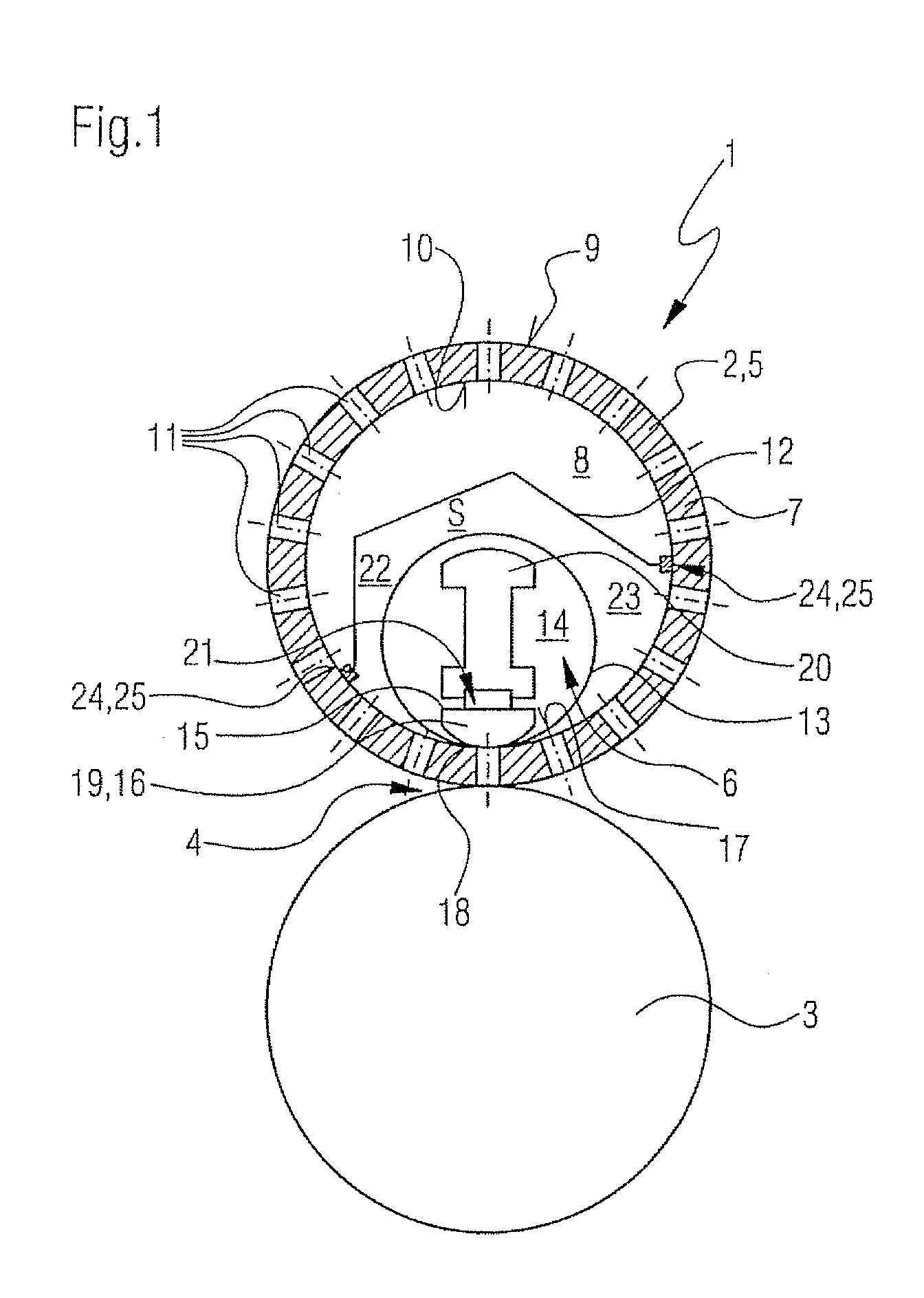

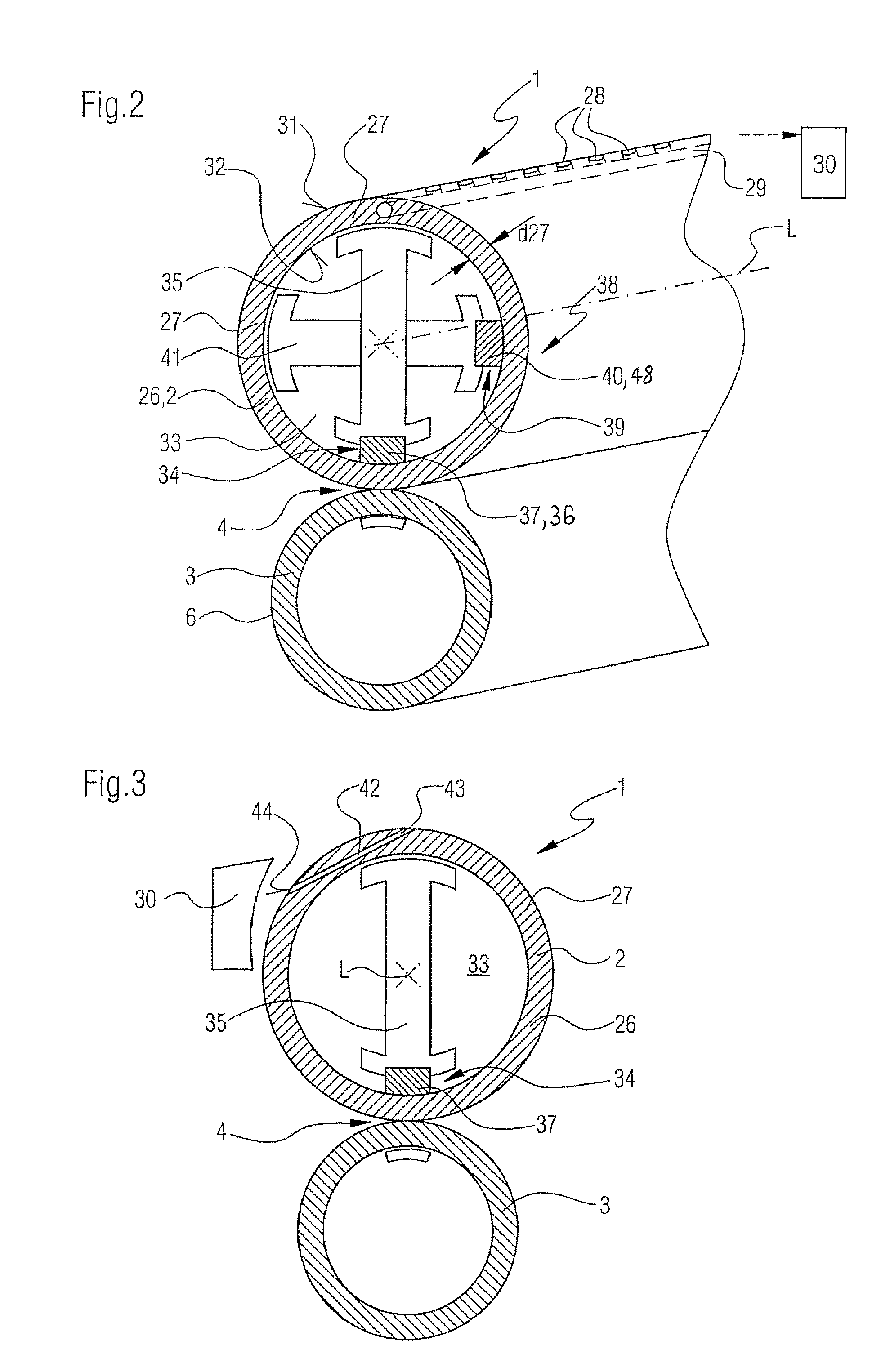

[0031]FIGS. 2 and 3 show in a schematic and highly simplified representation based on a perspective view a press device 1 with a compliance compensator according to the second basic embodiment. Here too the press device 1 includes two rolls, a first roll 2 and a second roll 3, whereby the first roll 2 is constructed as a suction press roll 26 and comprises a rigid roll cover 27. Both press rolls, the first press roll 2 and the second press roll 3, form together a press nip 4. The mating roll in the form of the second roll 3 can be constructed as various types. Said mating roll can be constructed as a shoe press roll with a flexible press cover with at least one pressing-on unit with a curved surface or as a solid roll 6. For example, the first roll 2 is constructed as an evacuated roll in the form of the suction press roll 26. Said suction press roll has, according to a first variant, on the surface of the roll cover 27 openings, in particular bores 28, which can be evacuated at the...

second embodiment

[0033]The second embodiment is characterized by a combination of the known characteristics of a rigid roll cover with openings for the purpose of evacuating or routing the fluid-gas mix through the cover 27 and an arrangement of a pressing-on unit 34 which becomes active at the inner circumference 32 of the roll cover 27 and braces said roll cover via said inner circumference on the supporting element, in particular yoke.

[0034]FIGS. 1 to 3 present possible embodiments of the suction press rolls. FIG. 4 presents a particularly advantageous use of inventively constructed suction press rolls 5 or 26 in a multiple-nip press apparatus 45 in the form of a Duocentri Nipcofiex press apparatus. FIG. 4 shows in a schematic and highly simplified representation a detail from the press apparatus 45 including a first press device 46 for forming three successively passable press nips together with a first roll 2 or a suction press roll 5 or 26 according to the first or the second embodiment, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com