Vacuum stabilized carry bag

a carry bag and vacuum stabilizer technology, applied in the field of carry bags, can solve the problems of discomfort for the bearer inability to tightly secure the contents of the carry bag, and exacerbate the problem of the carry bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

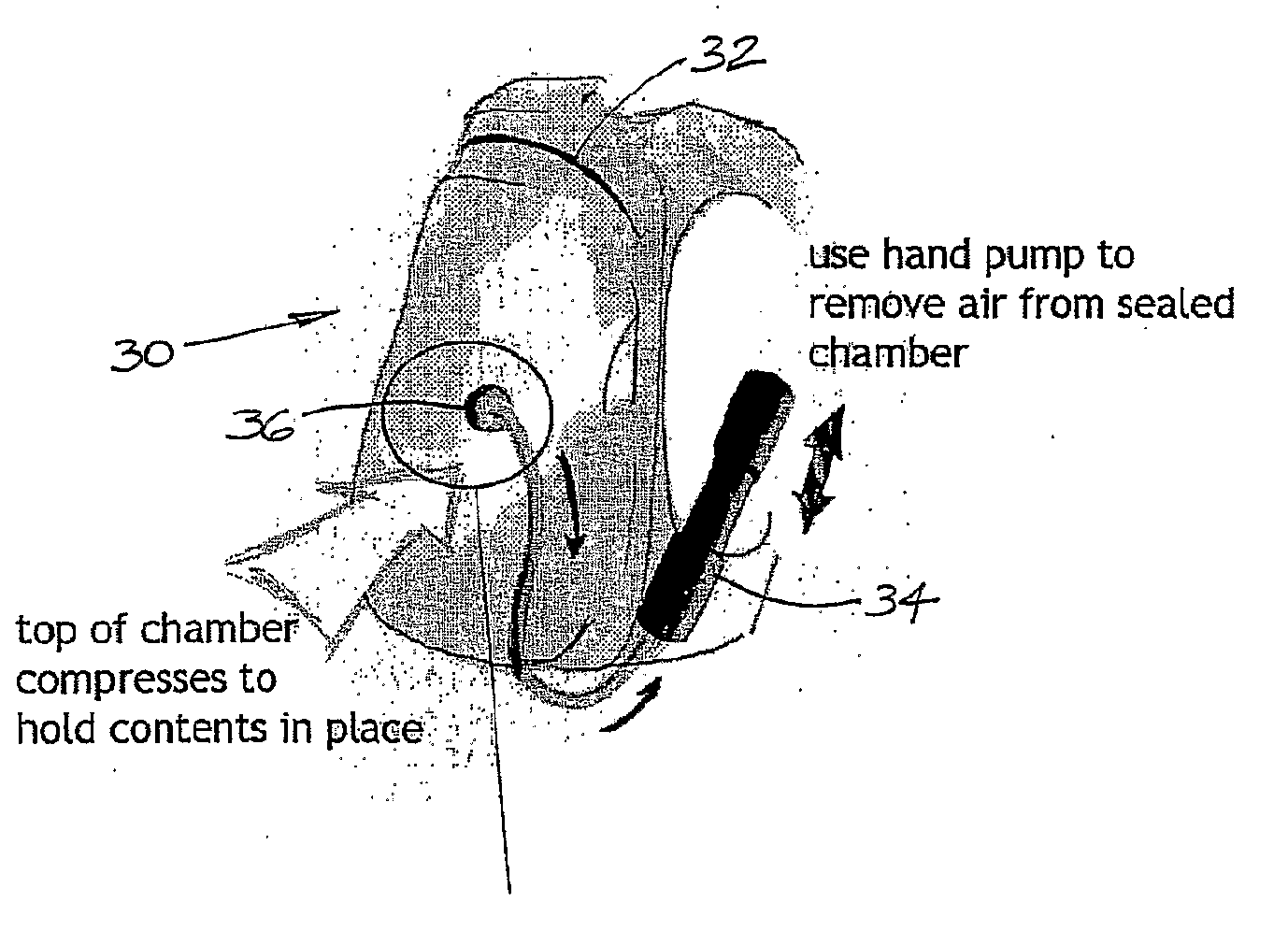

[0043]The carry bag 10 shown in FIG. 1 includes a base plate 12, an airtight bag 14 with a ziplock opening 16 and a suction pump coupling 18 attached to the airtight bag 14, and a protective outer sleeve 20 with a suction pump 22 attached thereto. Air can be evacuated from the bag 14 to compress any contents 24 therein against the base plate 12 in the manner as shown schematically in FIG. 2 by connecting the suction pump 22 to the coupling 18 and operating same.

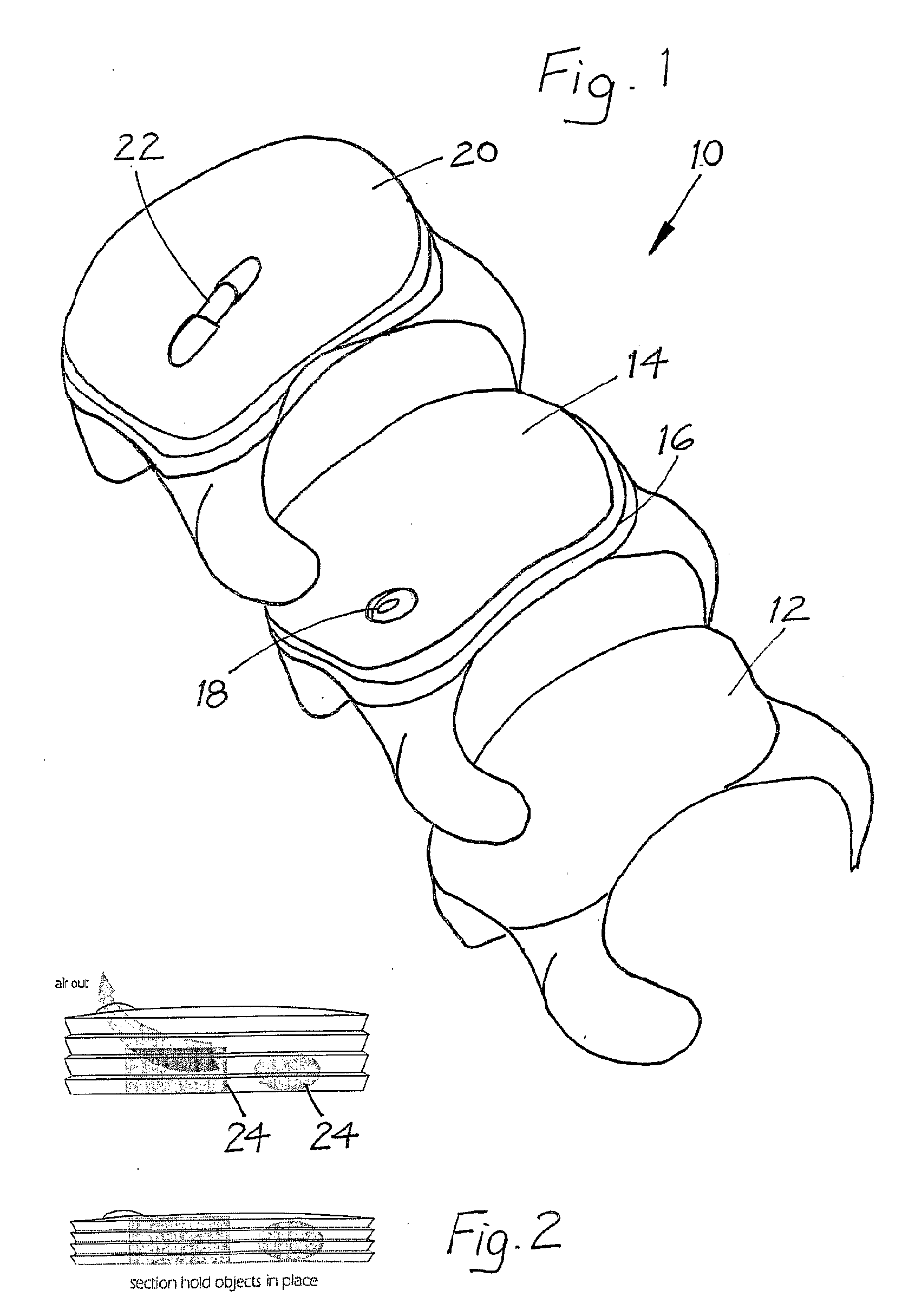

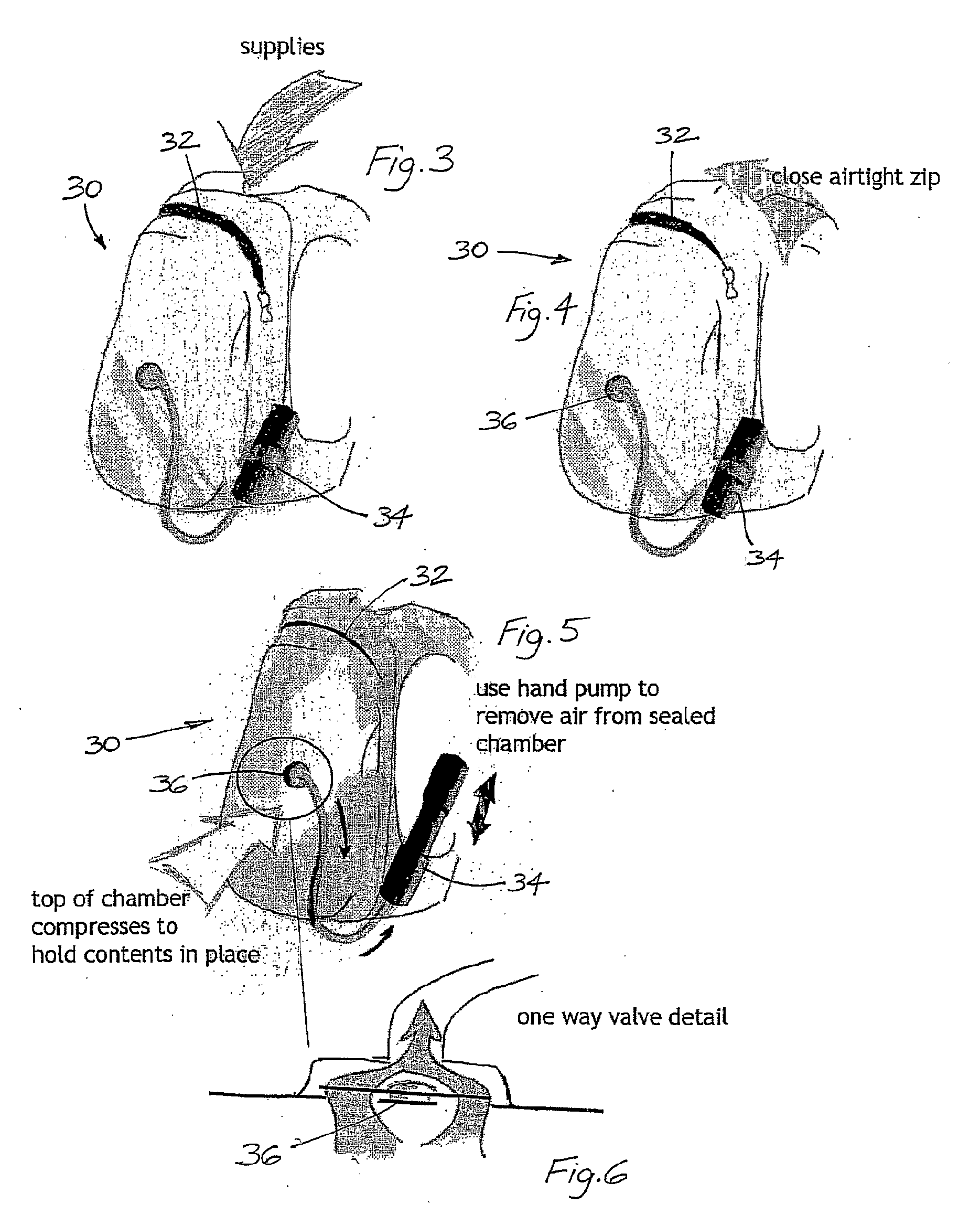

[0044]The carry bag 30 shown in FIGS. 3 to 5 is used, in a first stage, to receive contents through an outer sealable opening 32. The opening 32 is then closed to provide an airtight enclosure around the contents, and a hand pump 34 is then operated to evacuate air from the airtight enclosure. Flexible walls of the enclosure compress against the contents and hold them tightly in place. The one way valve 36 shown in FIG. 6 ensures that air cannot return into the enclosure during and after the operation of the hand pump 34.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com