Roofer's kneepads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

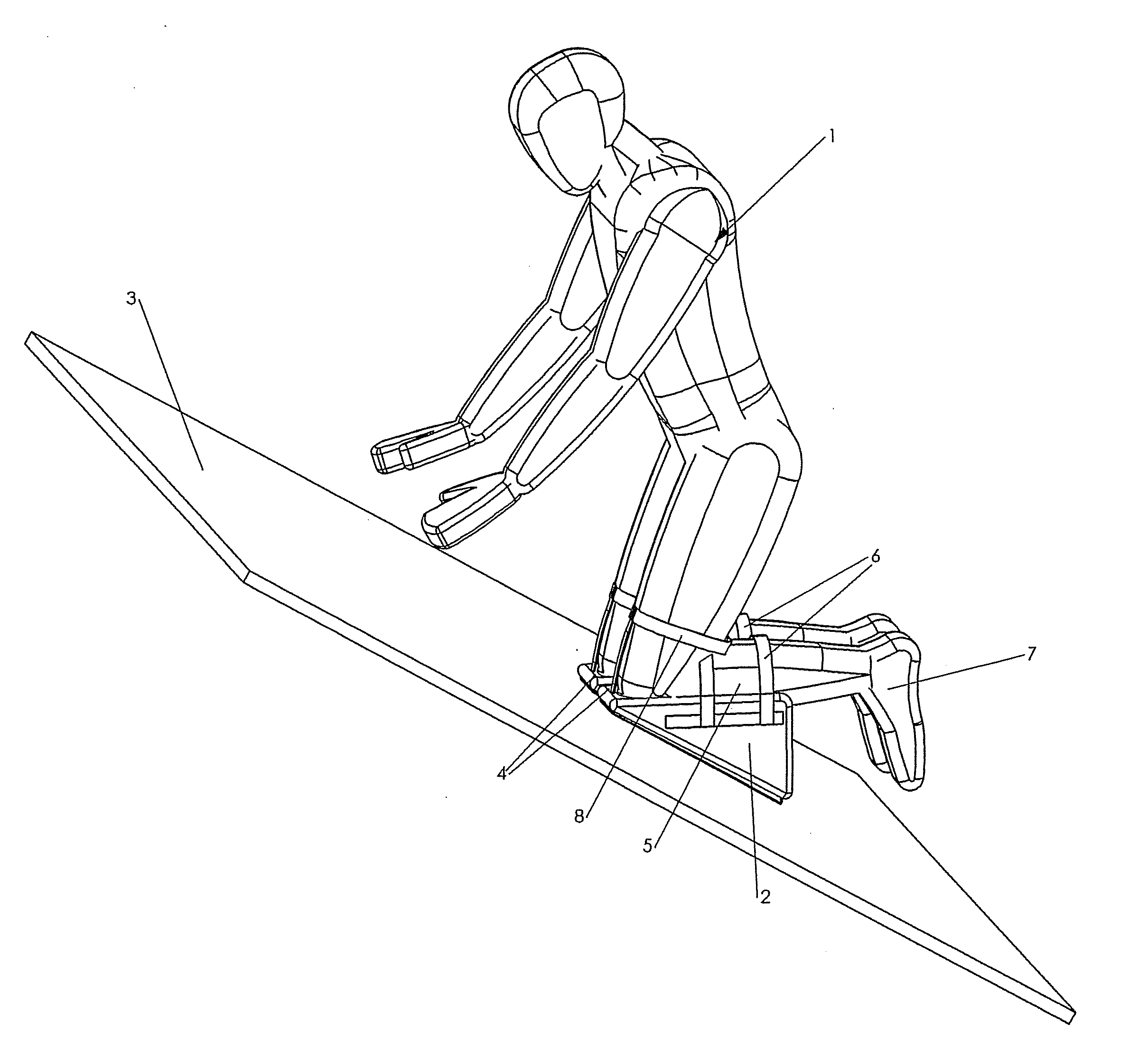

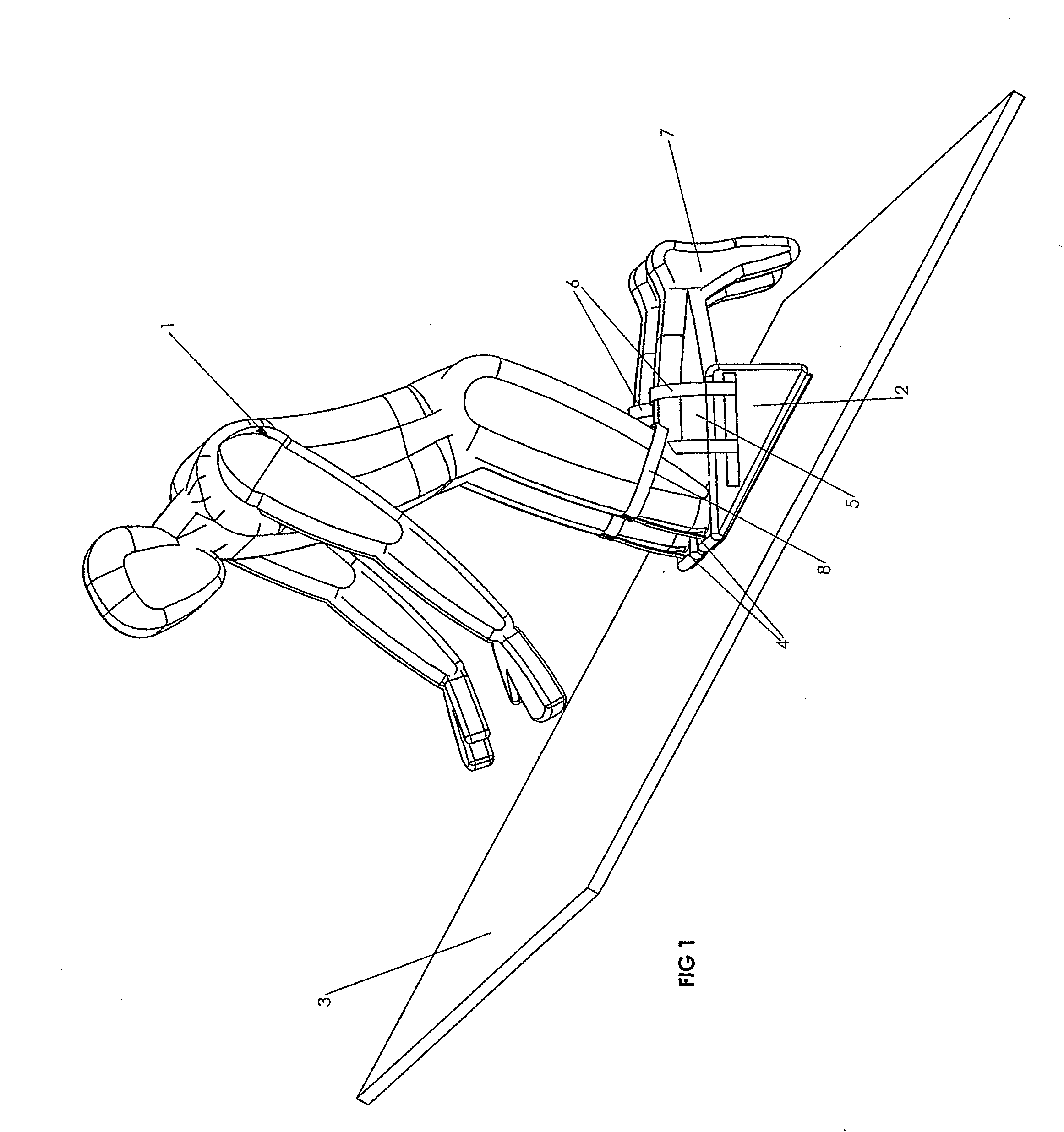

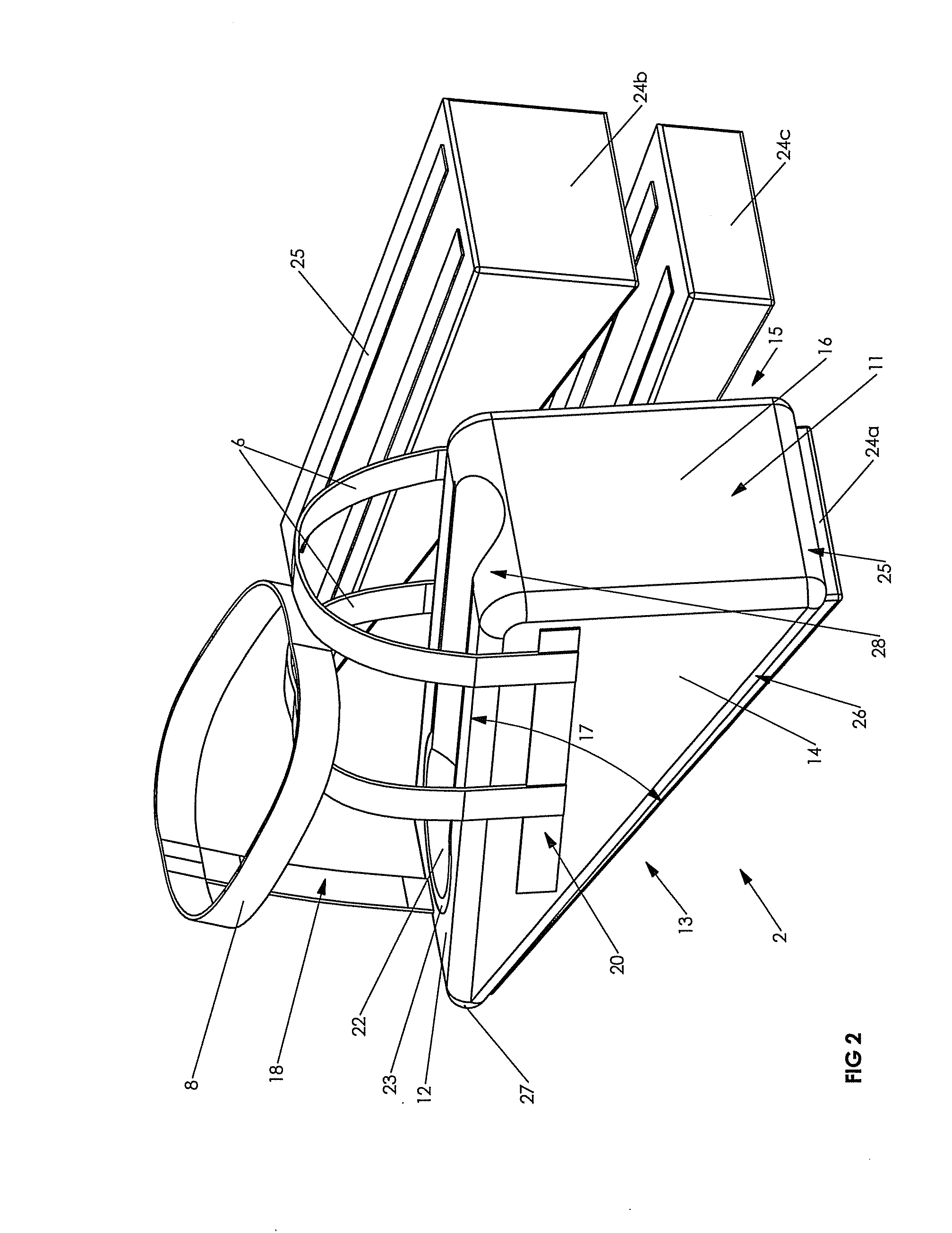

[0021]Referring to FIG. 1, roofer 1 is shown kneeling comfortably on inclined roof surface 3 using a pair of shin wedges 2 configured according to the present invention. The shape of the shin wedges is generally that of a wedge, having two non-parallel plane surfaces meeting at the thin side of the solid figure but not necessarily forming a sharp edge there. This shape could be described as a blunt wedge, but here is simply called “wedge”. The top surface may be not a flat plane, but rather (as will be described below) it may have a lengthwise depression to conform to the shin of the user. Opposite the thin blunt side is a thicker side to complete the solid triangle. The shin wedges are always worn so that the thin end is near the users knee (the proximal end) and the thick end is towards the foot (the distal end).

[0022]The shin wedge also usefully provides leverage, allowing the user to lever a knee up by rotation of the shin wedge about its distal edge.

[0023]In FIG. 1, for illustr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com