Vacuum shroud for use with drilling tools

a vacuum shroud and drilling tool technology, applied in the field of vacuum shrouds, can solve the problems of creating undesirable dust and debris, affecting the health of operators, and affecting the health of workers, and can be quite harmful to the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

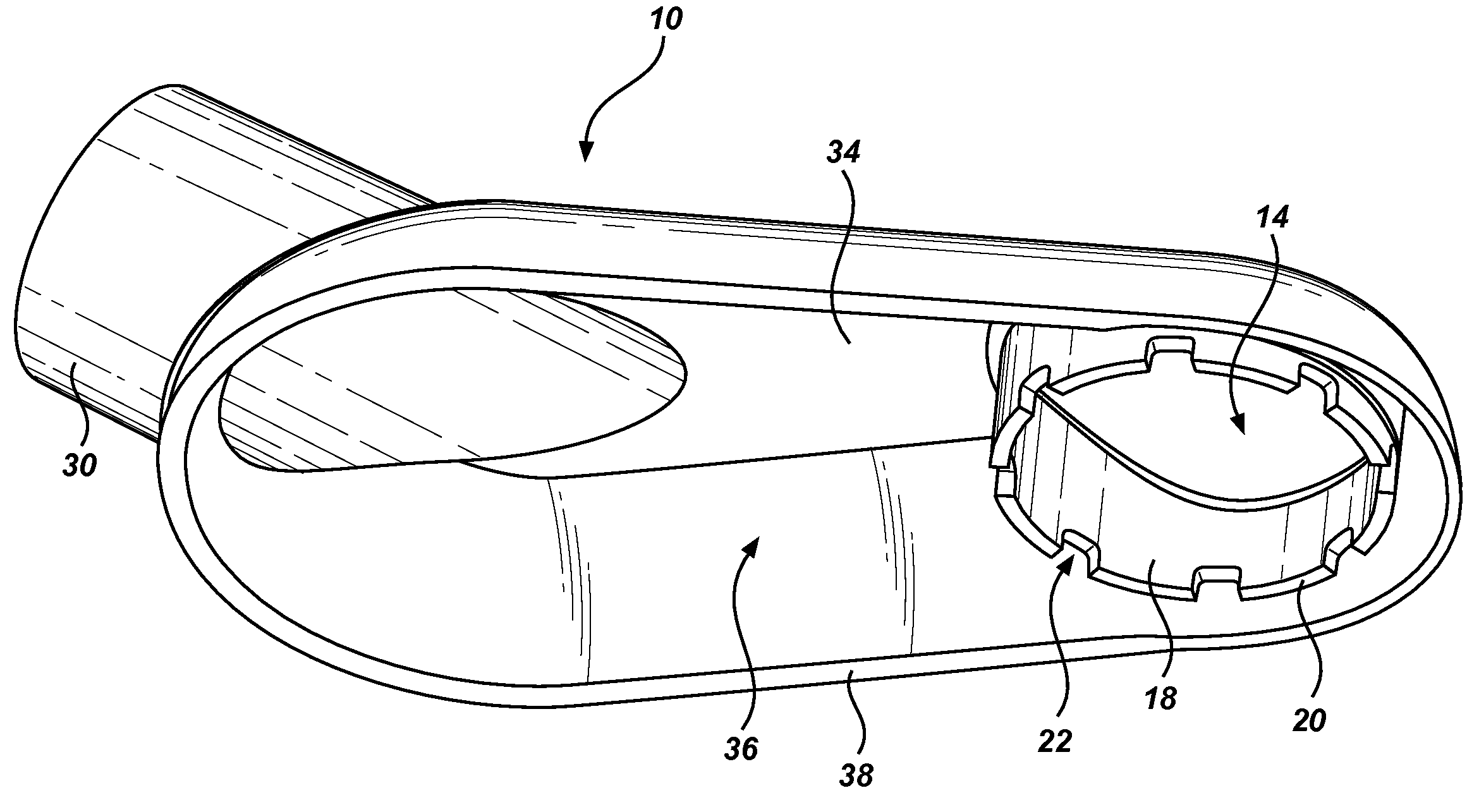

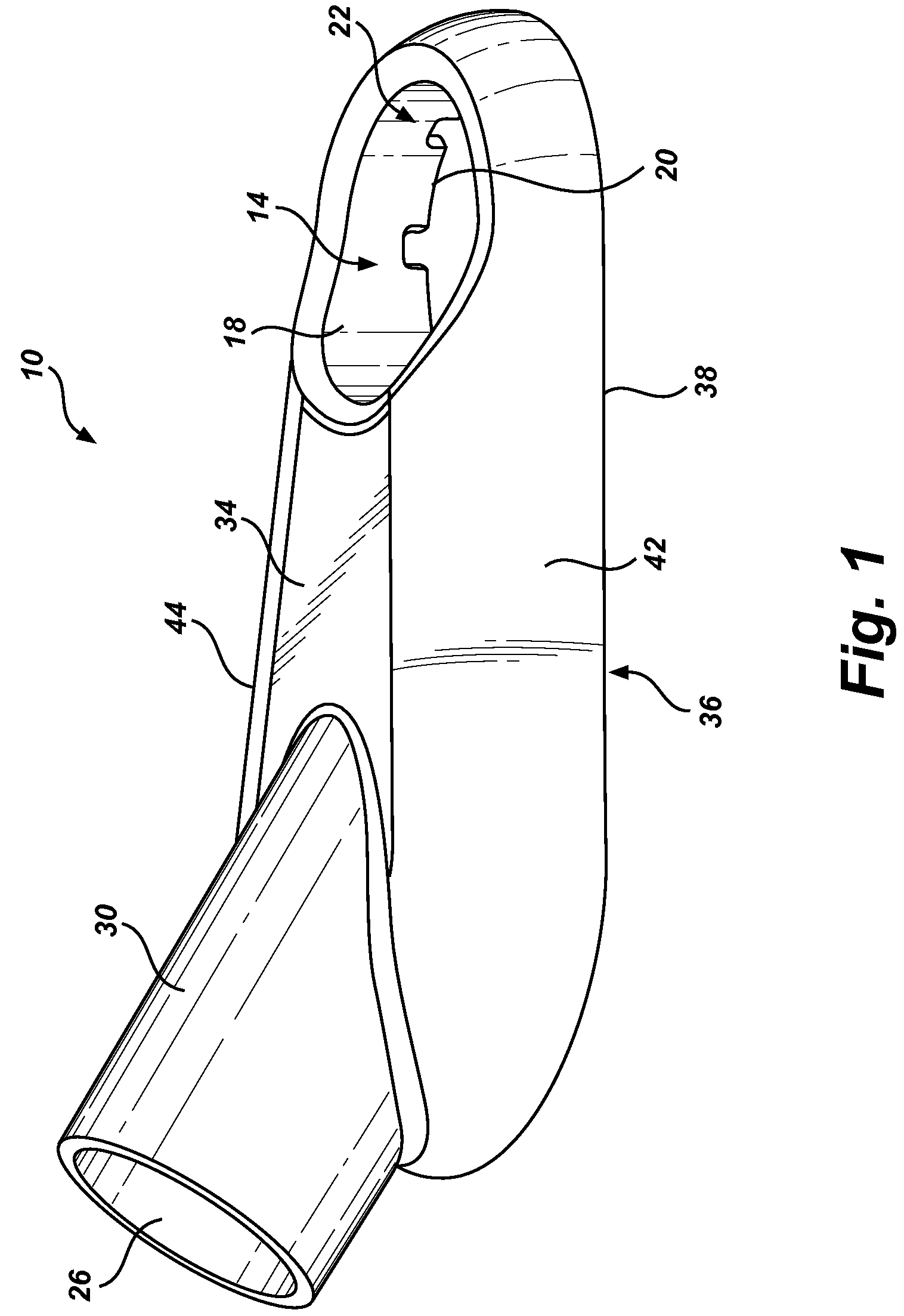

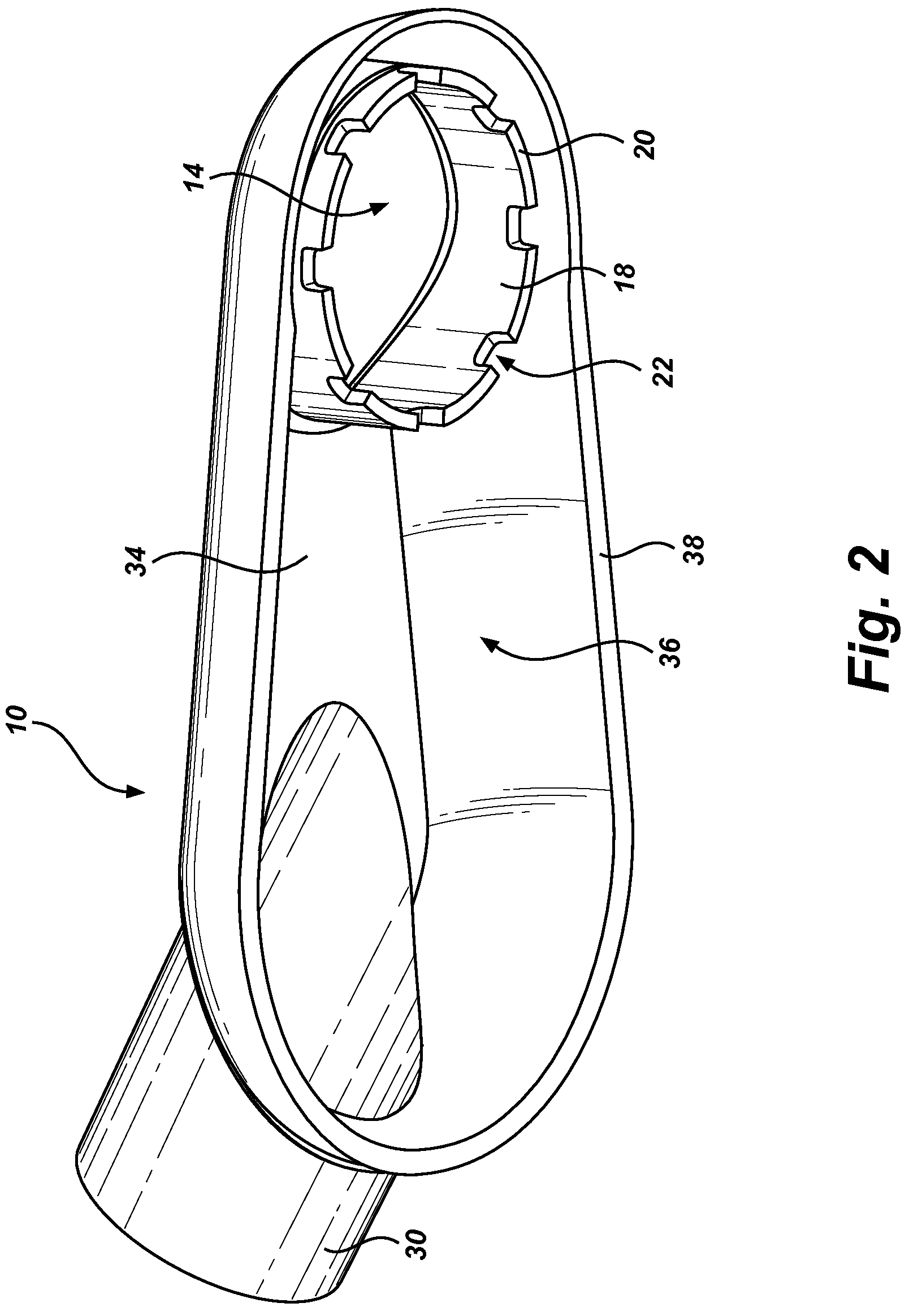

[0017]Turning now to FIG. 1, a top perspective view of an embodiment of a vacuum shroud for drilling tools is shown. Vacuum shroud 10 may include an upper surface 34 connected to lower edge 38, which may be configured to contact a work surface to be drilled, or a surface adjacent thereto. Upper surface 34 and lower edge 38 may be connected by sides 42 and 44, creating enclosed cavity 36 (see FIG. 2) between vacuum shroud 10 and the surface to be drilled.

[0018]Vacuum shroud 10 may include vacuum port 30 connected to upper surface 34 of vacuum shroud 10 with opening 26, which may be connected to a vacuum hose, or which may be formed integrally with a vacuum hose. Vacuum port 30 may also be open to cavity 36. Debris created by the drilling process may be removed by a vacuum (not shown) connected to vacuum port 30 through opening 26 through cavity 36.

[0019]Upper surface 34 of vacuum shroud 10 may include hole 14 generally enclosed by wall 18 extending from upper surface 34 of vacuum shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com