Pipe pulling assembly

a technology of pipe puller and assembly, which is applied in the direction of manufacturing tools, soldering devices, auxillary welding devices, etc., can solve the problems of two large diameter pipes, pipes, and inability to meet the requirements of prior art, and achieve accurate, safe and quick alignment. , the effect of accurate alignmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The best mode for carrying out the pipe pulling assembly is presented in terms of a preferred embodiment that allows two large diameter pipes to be accurately, safely and quickly connected together.

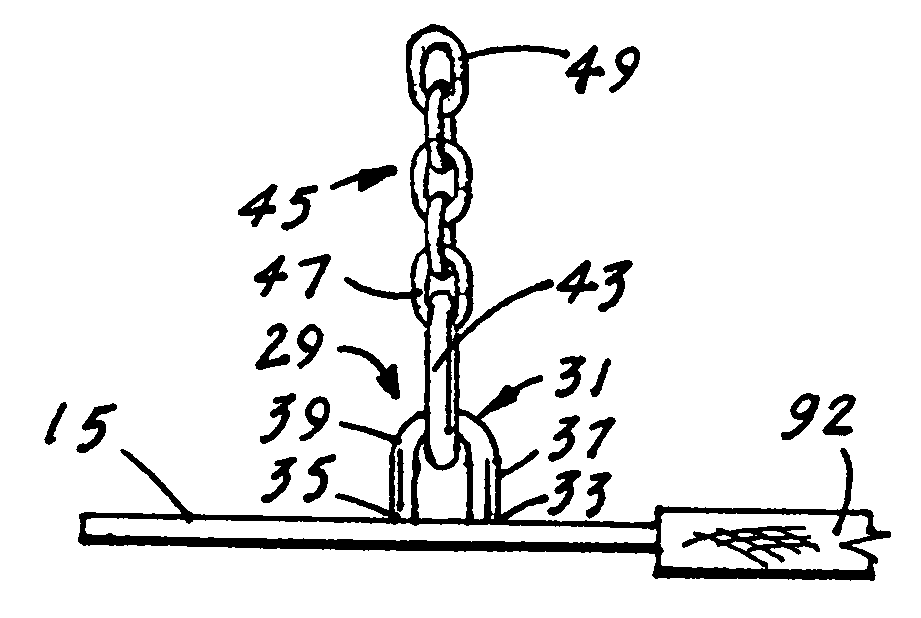

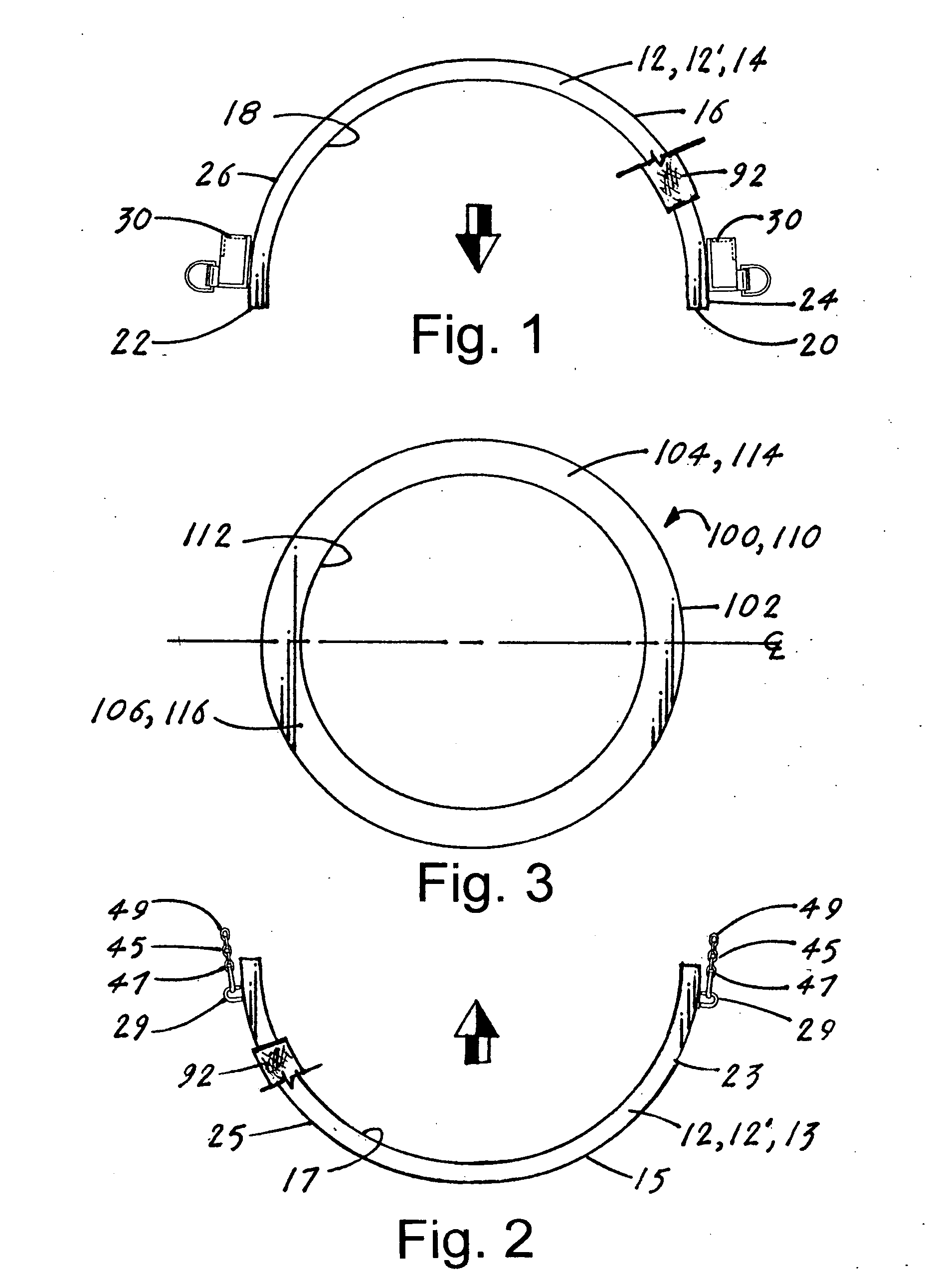

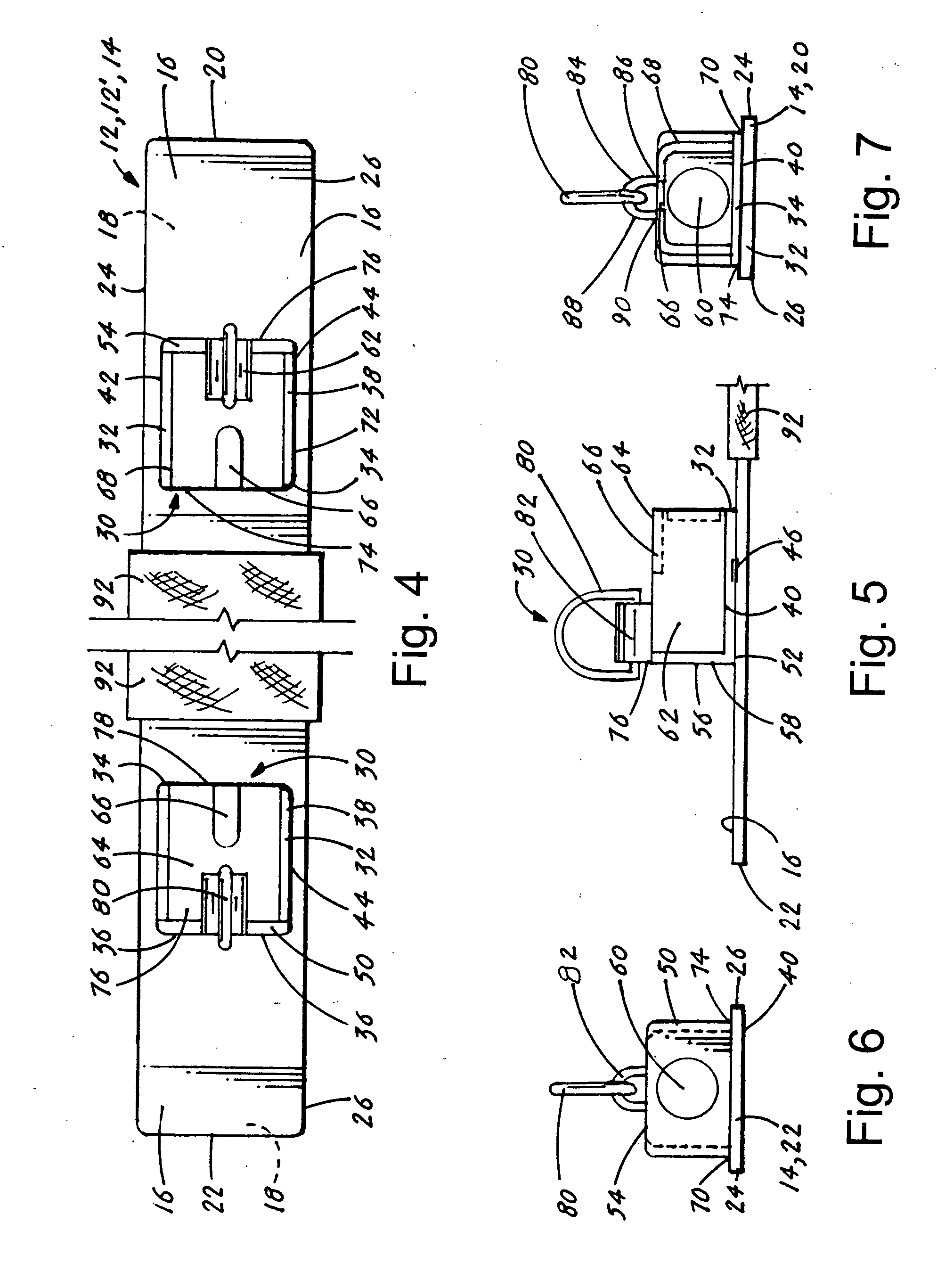

[0046]The preferred embodiment of the pipe pulling assembly 10 (hereinafter “PPA 10”), as shown in FIGS. 1-12, is comprised of a first circular band 12 and an identical second circular band 12′ that are designed to function in combination with a first circular pipe 100 and a second circular pipe 110. The first circular pipe 100 has an outer diameter 102, an upper section 104 and an integral lower section 106. The second circular pipe 110 has an inner diameter 112, an upper section 114 and an integral lower section 116. The inner diameter 112 on the second circular pipe 110 is larger than the outer diameter 102 of the first circular pipe 100 to allow the first circular pipe 100 to be inserted into and attached to the second circular pipe 110. The PPA 10 is particularly useful when at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com