System, air valve assembly and method for air evacuation of plastic sealable storage bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

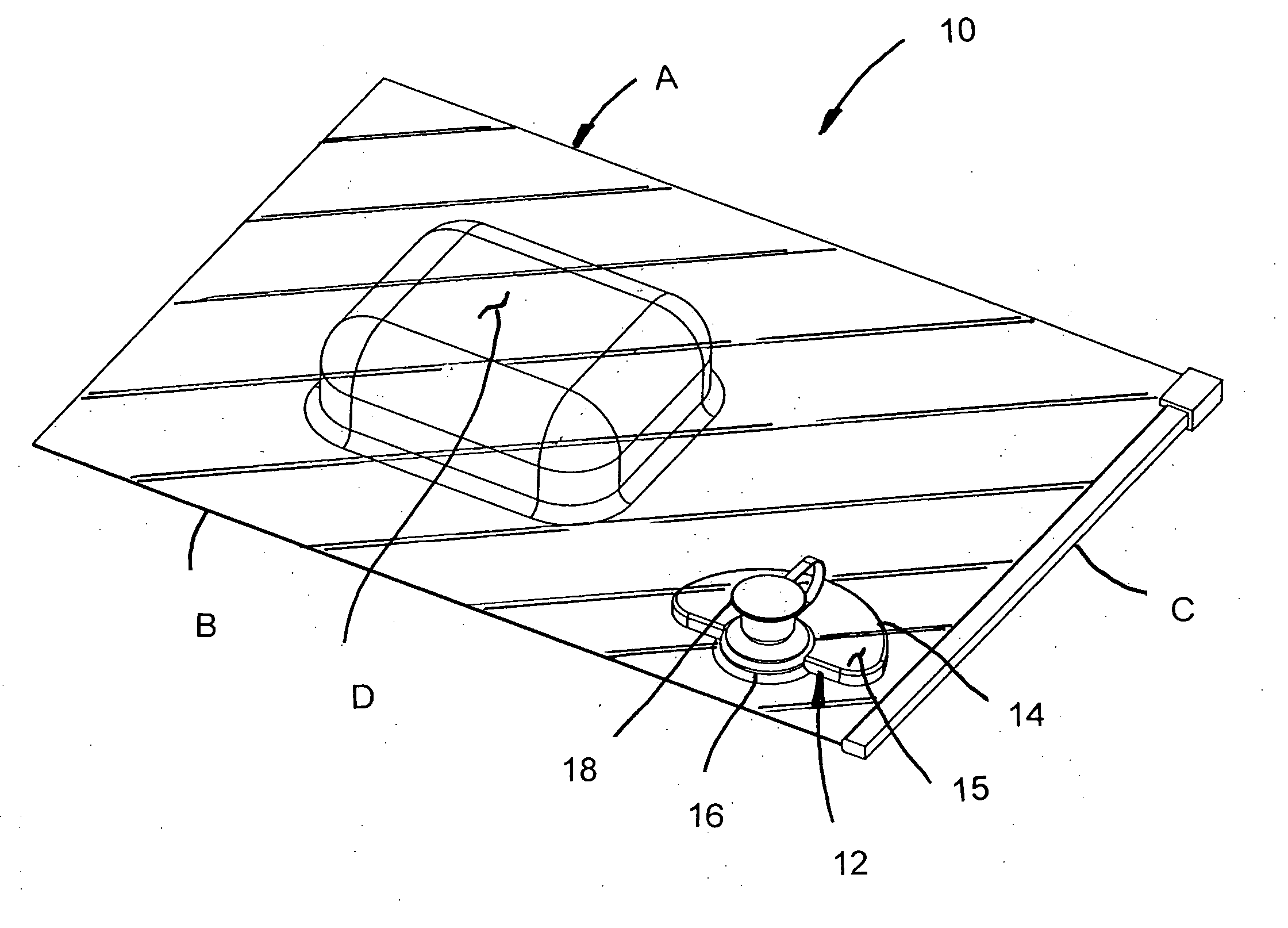

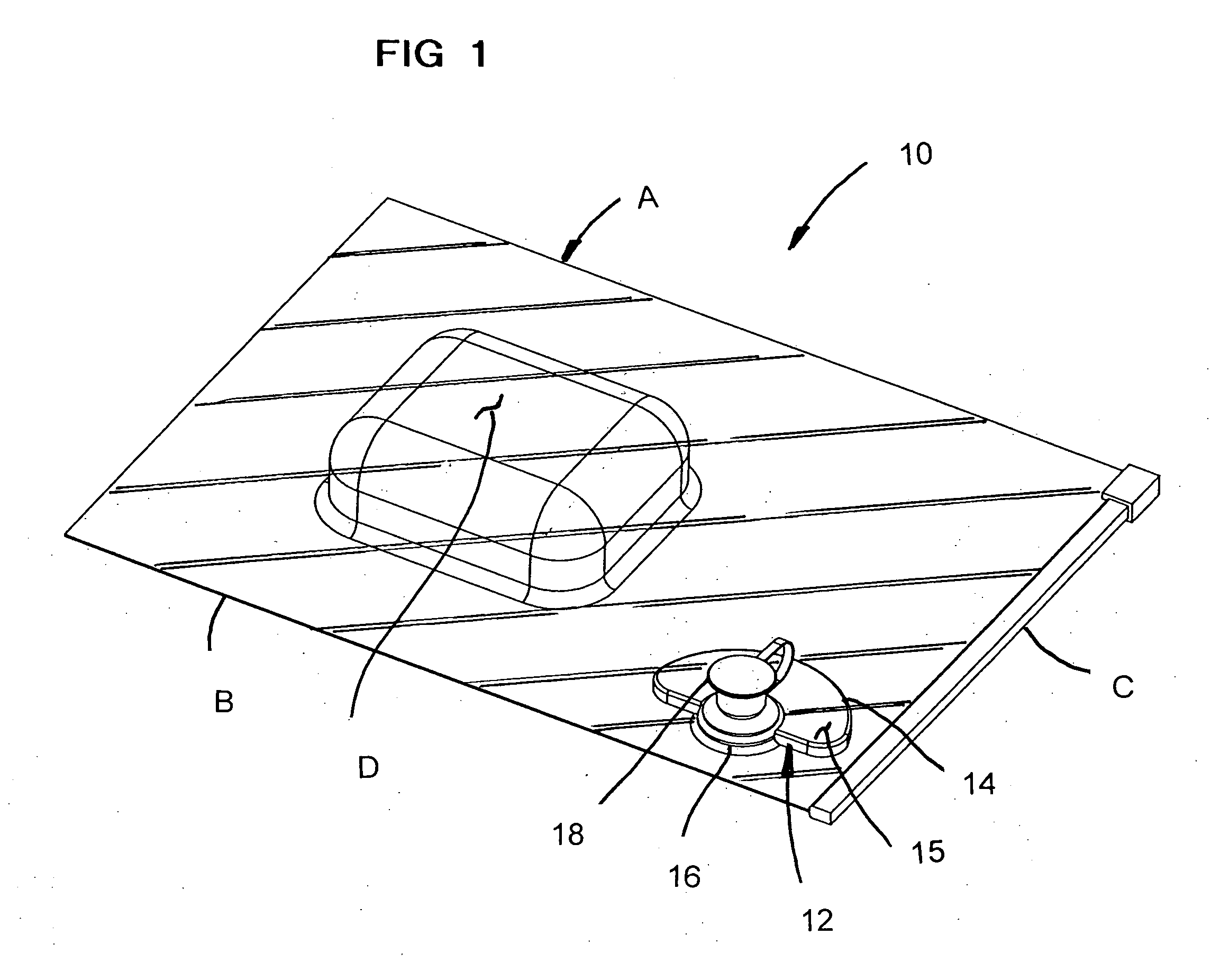

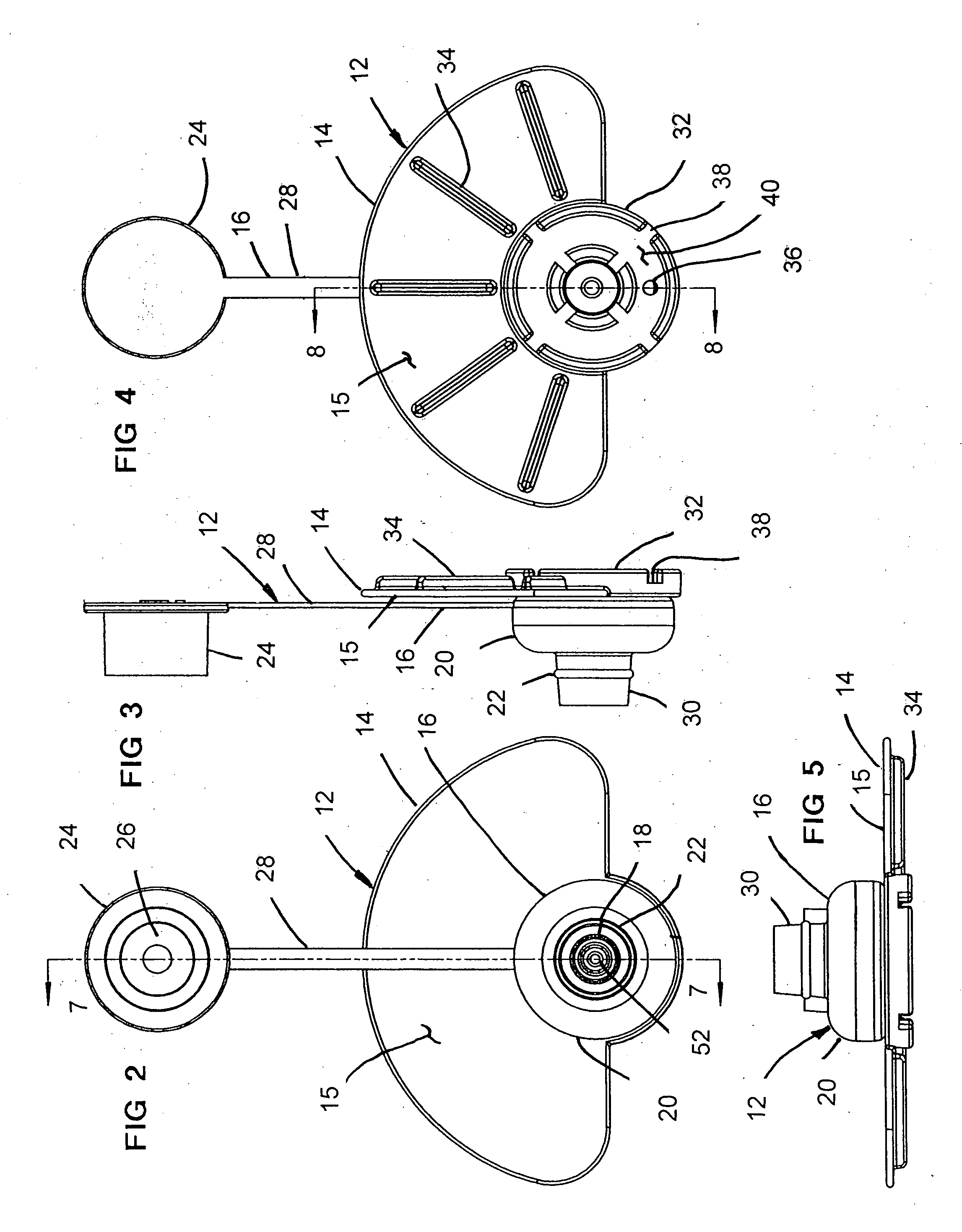

[0040]Referring now to the drawings, and firstly to FIGS. 1 to 8, the system of the invention in combination with a conventional plastic storage container or bag A is there shown generally at numeral 10. The system 10 includes an air valve assembly 12 which includes an inner valve member 14 and an outer valve member 16 installed into the conventional plastic storage bag or container A.

[0041]Initially, a food item or other storable goods D is placed within the open sealable end C of the bag A. Prior to this, the air valve assembly 12 was assembled onto one of the flexible side panels of the bag B as will be described in more detail in FIGS. 7 and 8. After installation of the air valve assembly 12 and insertion of the item D to be vacuum-sealed within the flexible storage bag A, the sealable end C is closed. Thereafter, a vacuum pump is utilized in conjunction with the air valve assembly 12 to evacuate substantially all air from within the sealed storage bag A, again as will be descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com