Protective cover for a valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

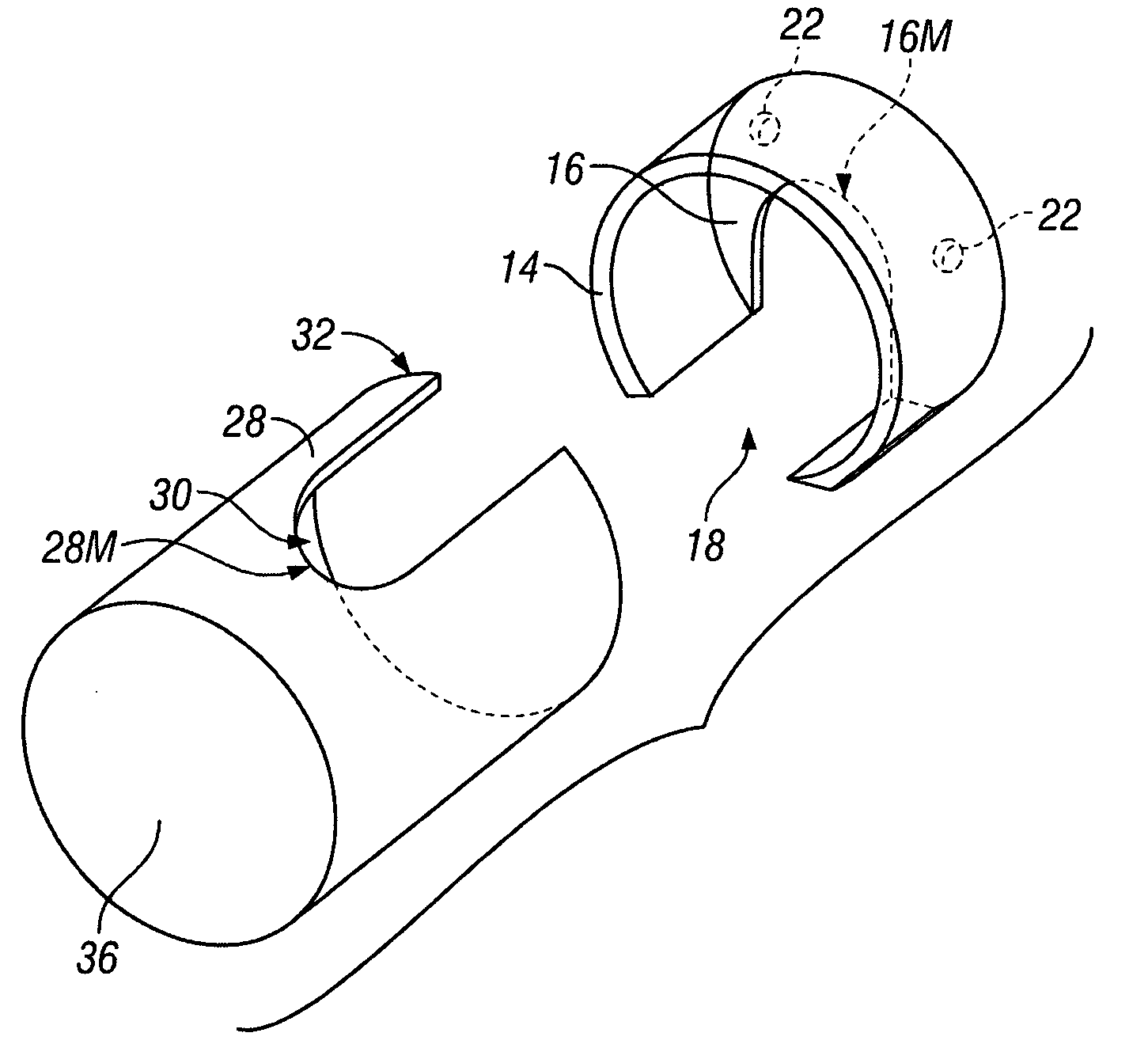

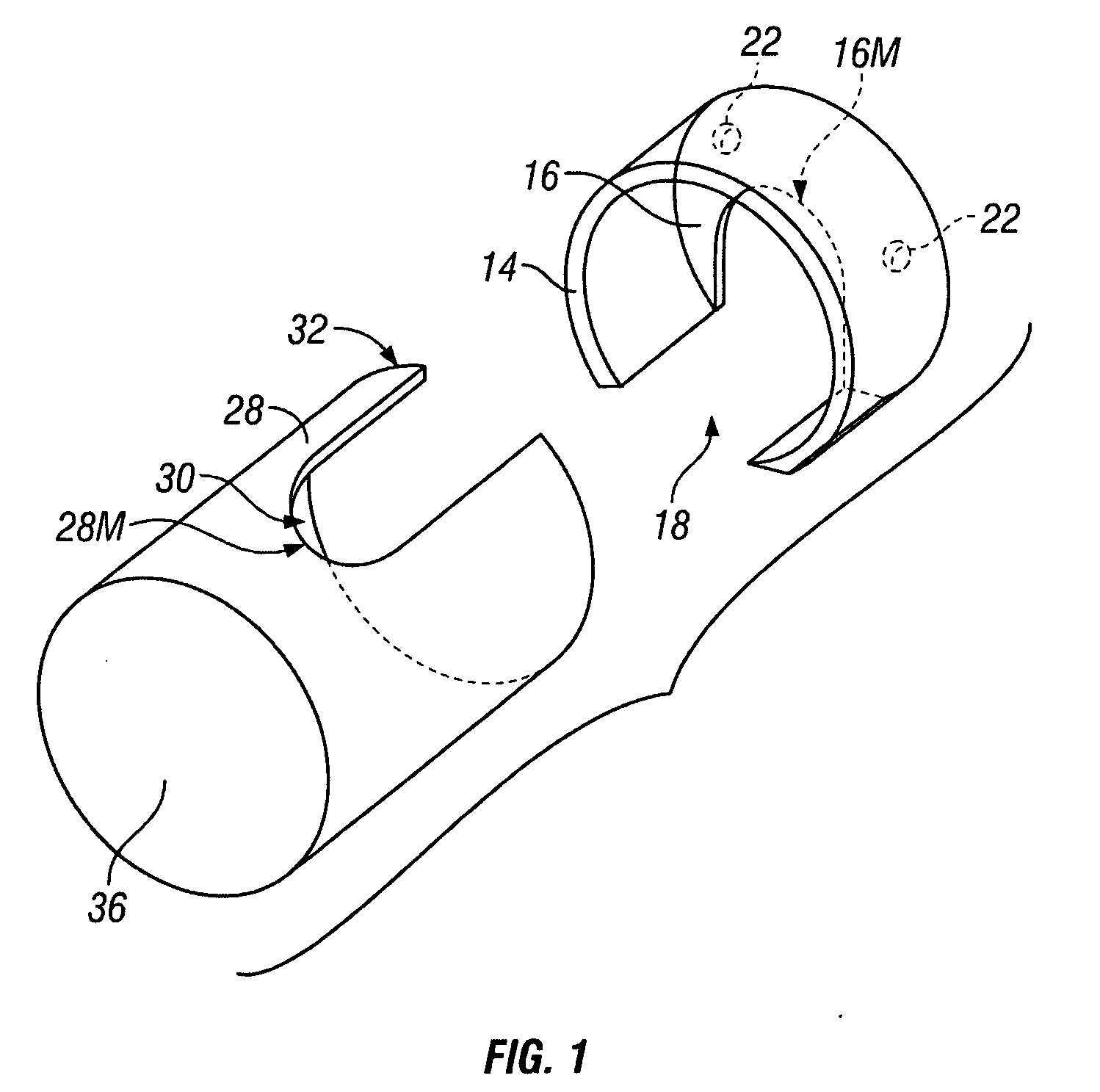

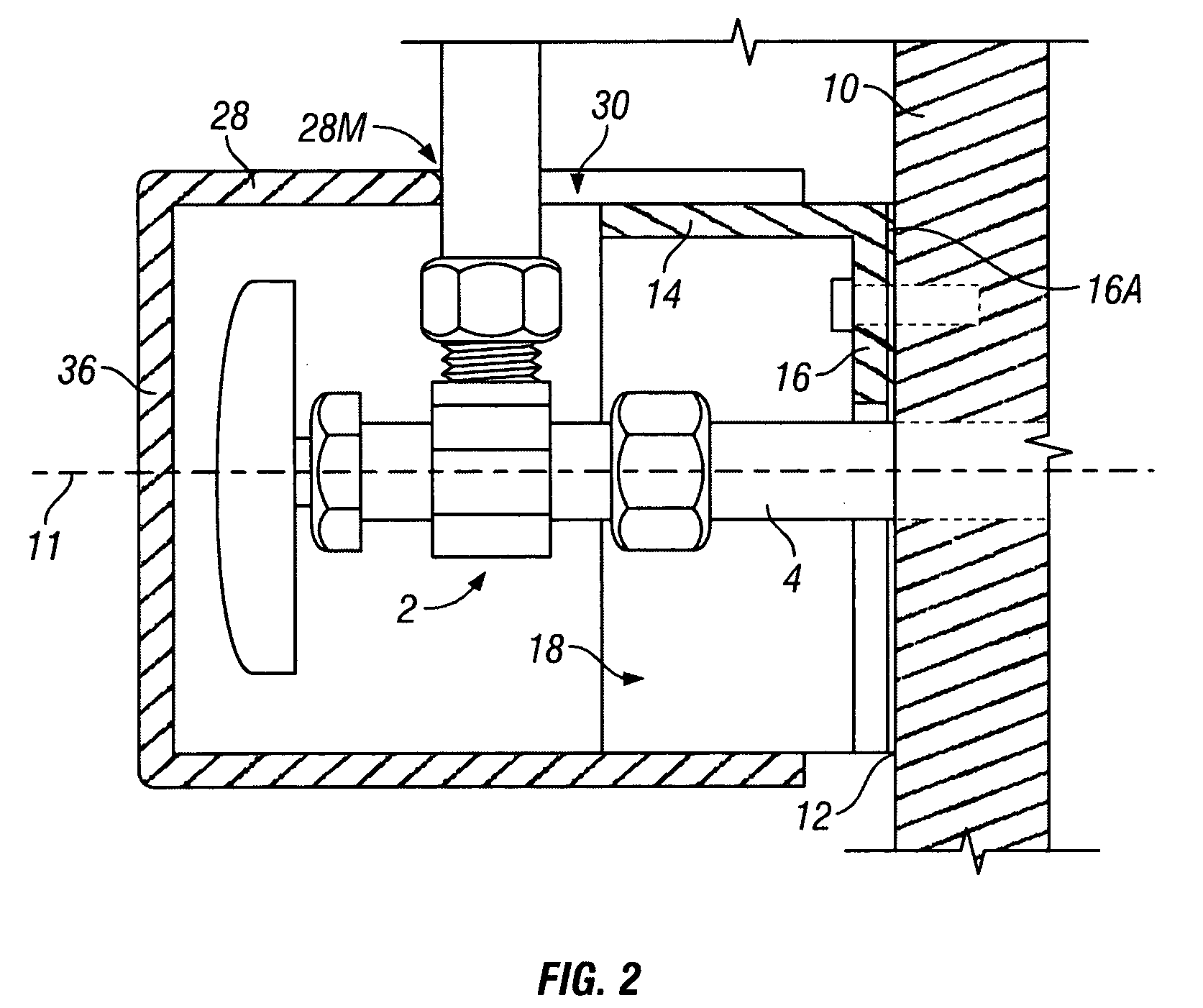

[0025]In a first embodiment shown in FIGS. 1 and 2, the apparatus provides a base cylinder wall 14 aligned with the longitudinal axis 11 and terminating distally with an integral base end wall 16. The base cylinder wall 14 has a base slot 18 extensive longitudinally therethrough. The slot 18 is contiguous through the base end wall 16 radially to a medial position 16M in the base end wall 16. This is clearly shown in FIG. 1.

[0026]A cover cylinder wall 28 is aligned with the longitudinal axis 11 and frictionally engaged with the base cylinder wall 16 as shown in FIG. 2. The cover cylinder wall 28 has a cover slot 30 extensive longitudinally therethrough from a distal end 32 of the cover cylinder wall 28 to a medial position 28M therein. The cover cylinder wall 28 preferably has a proximal cover end wall 36 integral with the cover cylinder wall 28 as shown in FIGS. 1 and 2, but the end wall 36 may be omitted as shown in FIGS. 3 and 4.

[0027]The base end wall 16 preferably has a means fo...

second embodiment

[0028]In the present invention, shown in FIGS. 3 and 4, the base cylinder wall 14 and base end wall 16 are replaced by a base block 140. The base block 140 has an outer surface 142 and an opposing concave inner surface 144, wherein the outer and inner surfaces 142 and 144 are longitudinally extensive between a distal 146 and a proximal 148 planar surfaces. The base block 140 has the shape of an inverted “U” as is clearly shown in FIG. 3.

[0029]The same cover cylinder wall 28 as described in the first embodiment above is also used here in the second embodiment. The cover cylinder wall 28 is aligned with the longitudinal axis, as before, and is frictionally engaged with the outer surface 142 of the base block 140. The adhesive 12 may be applied to base block surface 146 to mount the base block 140 to wall surface 10 as above. Alternately, the base block may have mounting holes therethrough, extensive between the distal 146 and proximal 148 planar surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com