Downhole tool with protective covering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

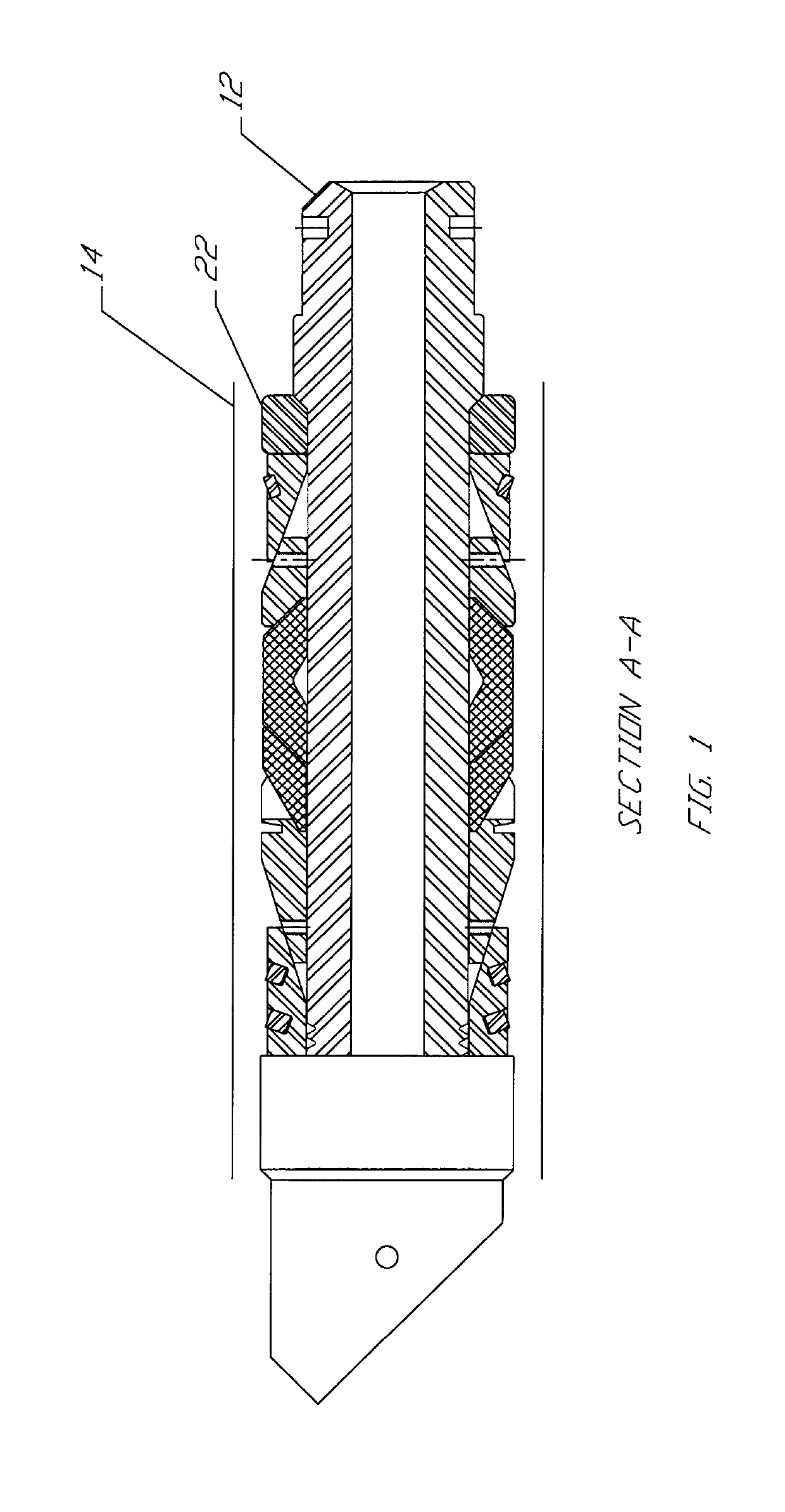

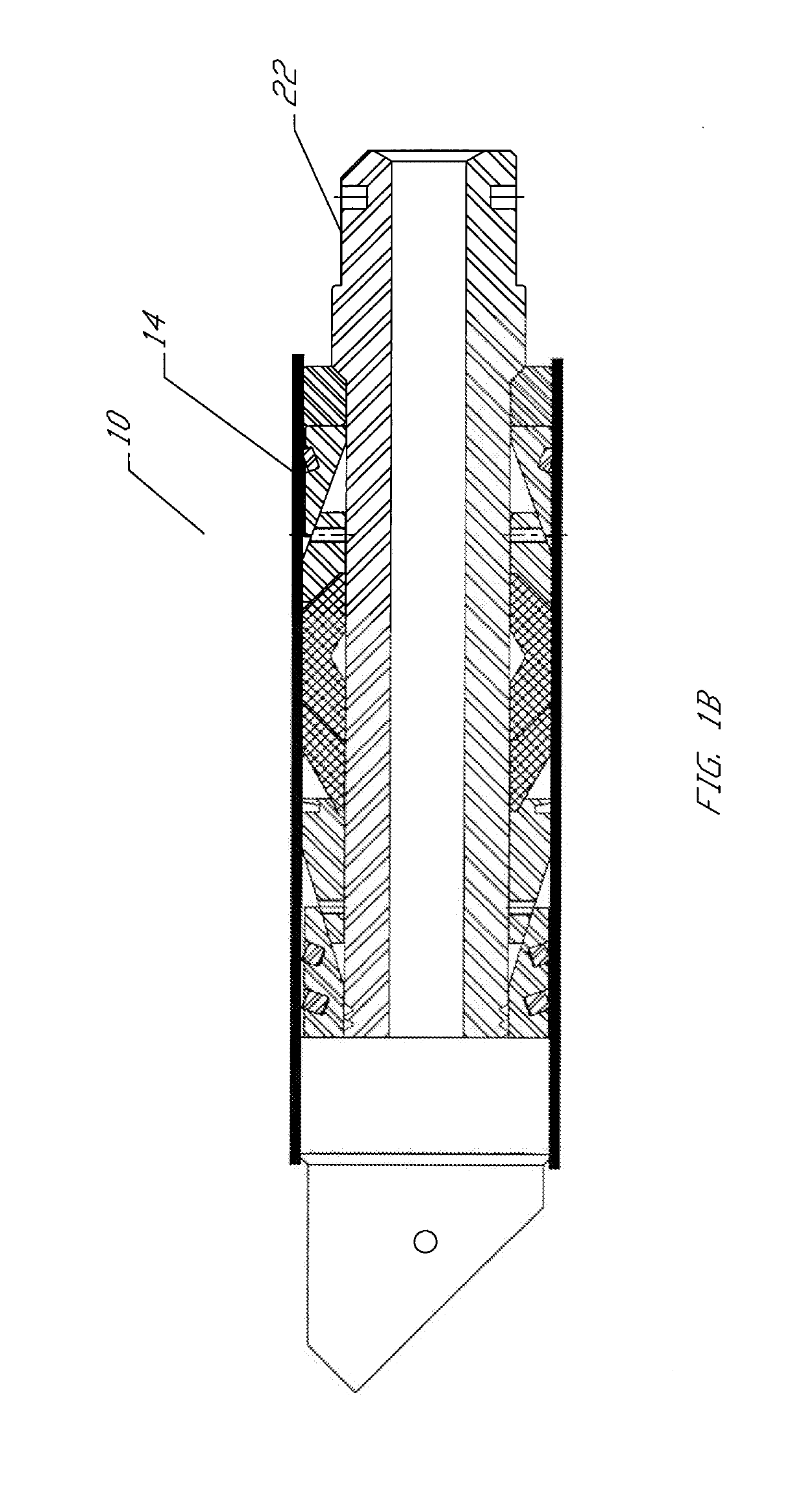

[0040]FIG. 1 illustrates downhole tool 12 having an outer surface 22, including sidewall 12a, bottom wall 12b and top wall 12c (see FIG. 3C) at least partially covered by an unshrunk wrap 14. FIG. 1 illustrates a preshrunk wrap about the tool. FIG. 1A illustrates a wrap shrunk tight about the tool so the wrap follows the contours of the outer surface of the tool. FIG. 1B illustrates the wrap in a smooth shrunk condition, achieved by using less heat than used to achieve the shrink tight configuration of FIG. 1A and useful in some embodiments as further described herein.

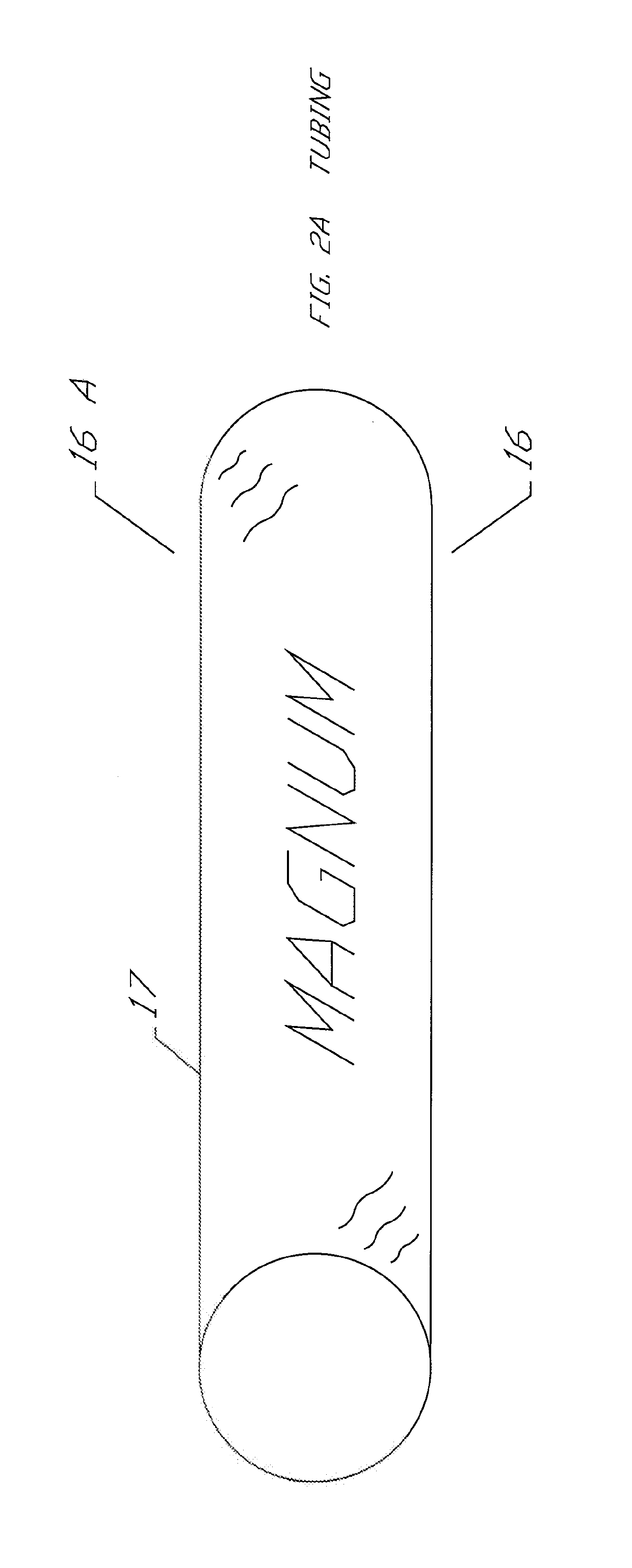

[0041]FIGS. 2A, 2B and 2C illustrate three forms of heat shrinkable material that may be used to form a wrap 14. FIG. 2A illustrates a heat shrink material comprising a sleeve or tube 16 (open at both ends), typically cylindrical, and, in some embodiments, somewhat stiff, and having a diameter selected to receive the tool therein. In FIG. 2A, the tube has indicia 17 on its surface, the indicia including, for example, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com