Polymeric microspheres

a polymer and microsphere technology, applied in the field of microsphere particles, can solve the problems of restricting the use of such particles, difficult to achieve, and control the thickness of the shell, and achieve the effect of increasing the strength and durability of the polymeric shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

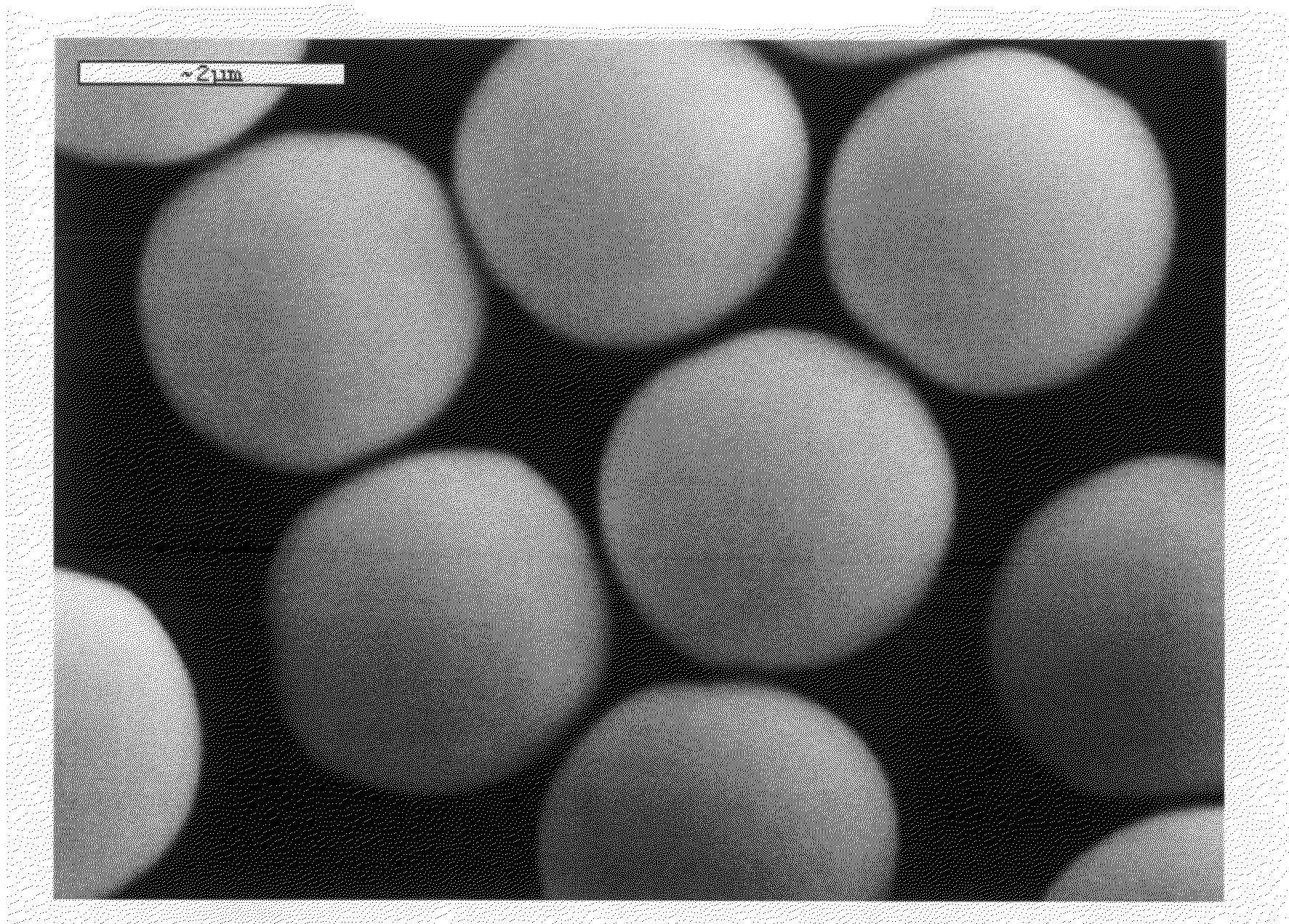

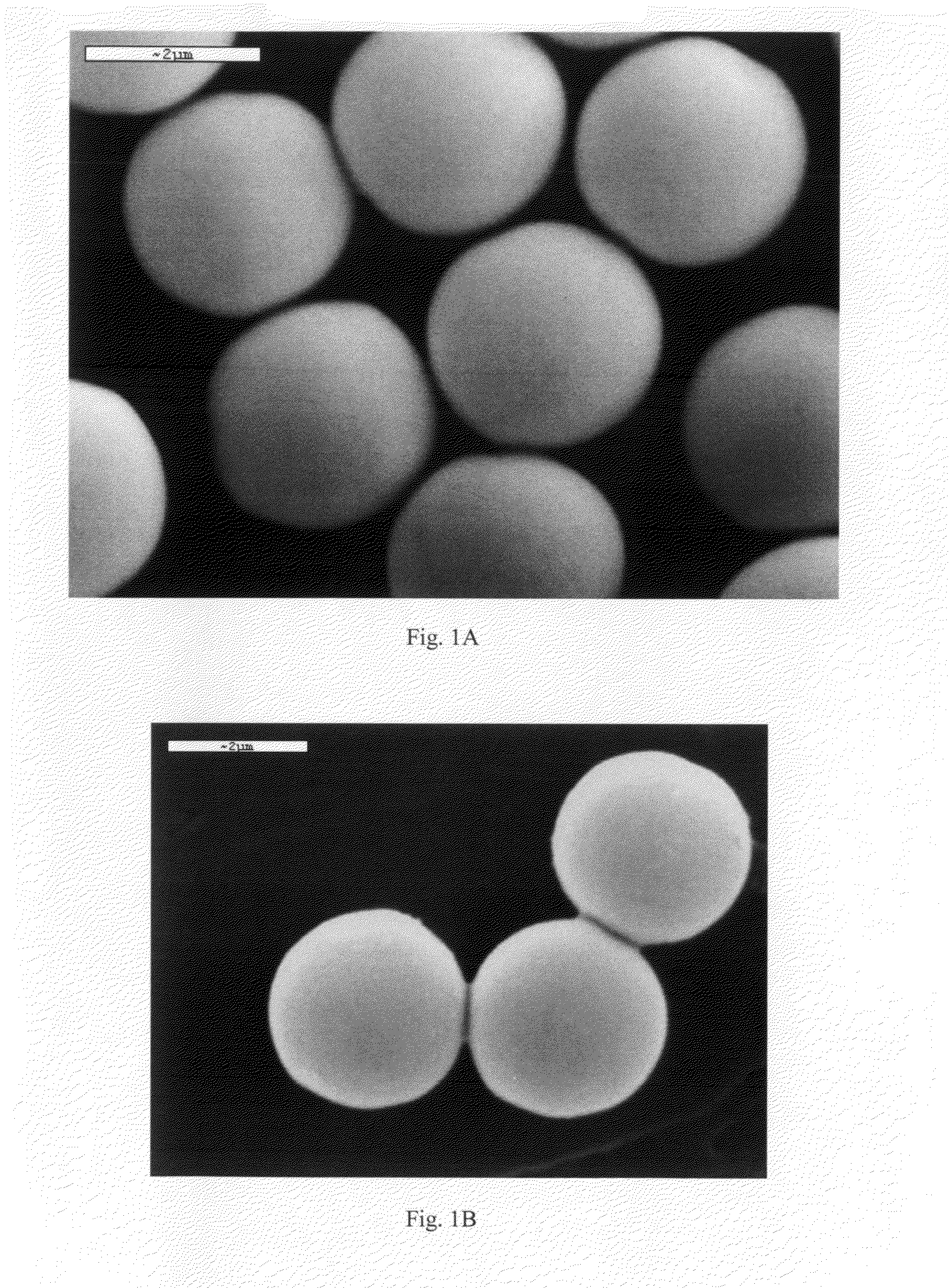

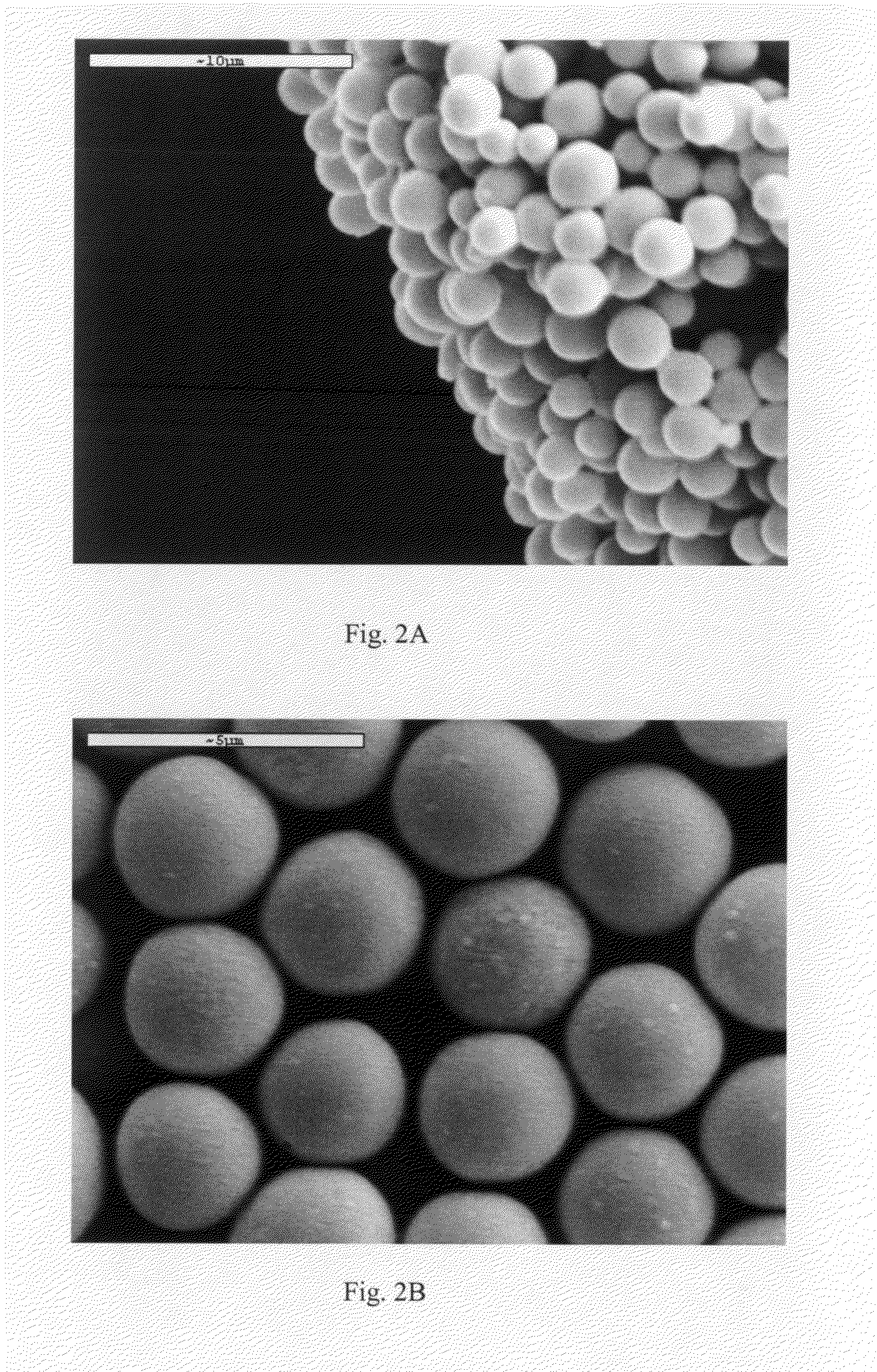

[0039]Hollow polymer microspheres were prepared by coating silica microsphere templates with poly(benzyl methacrylate) using surface initiated controlled / living radical polymerization and subsequently removing the core by chemical etching. Shell thickness was controlled by varying the polymerization time. Scanning electron microscopy was used to characterize the products and demonstrate that the polymer microspheres were hollow. FTIR spectroscopy showed that the silica cores were completely removed by etching.

Surface Confined Living Radical Polymerization: A New Method for Preparing Hollow Polymer Microspheres on Silica Templates.

[0040]Uniform hollow polymeric microspheres were made by using surface confined living radical polymerization. Using the silica microsphere as a sacrificial core, hollow microspheres were produced following core dissolution. First, a controlled / living polymerization was conducted using an initiator attached to the surface of silica microparticles to initiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap