Crib Mattress Sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

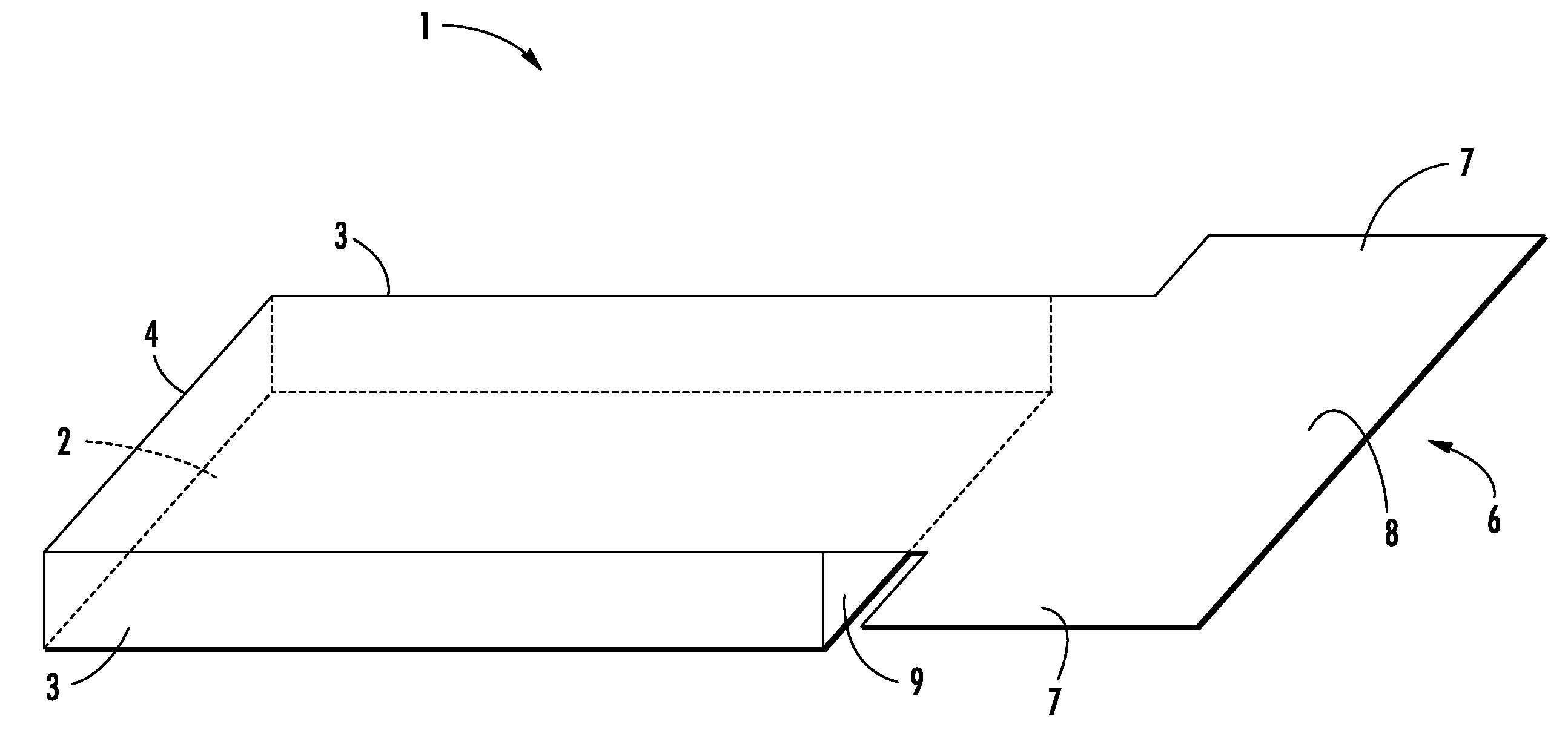

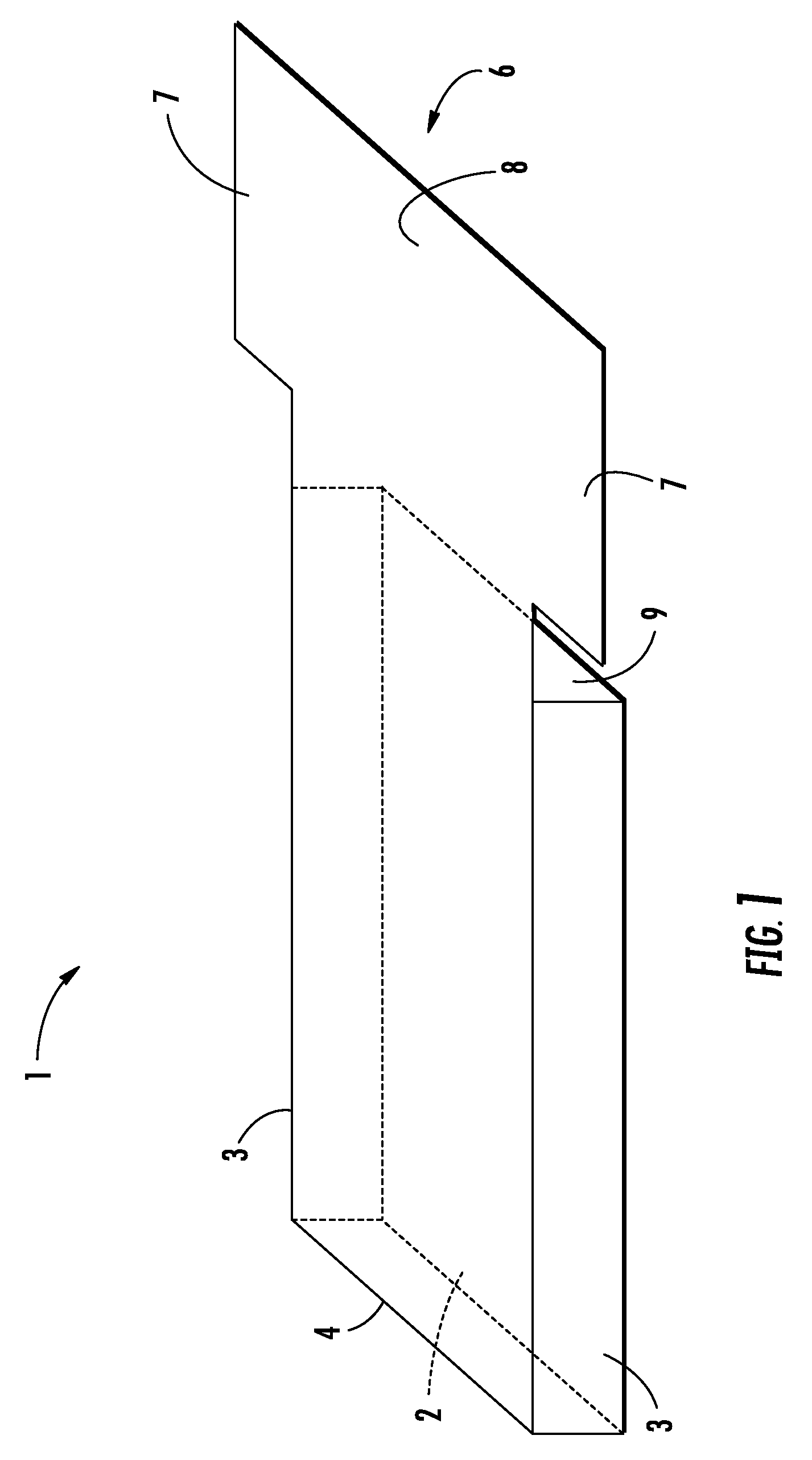

[0023]With reference to FIG. 1, a preferred embodiment of the invention comprises a top panel (1), a bottom panel (2), two lateral side panels (3) and an end panel (4). The panels are constructed of suitable fabric and sewn together to form an enclosure for a crib mattress.

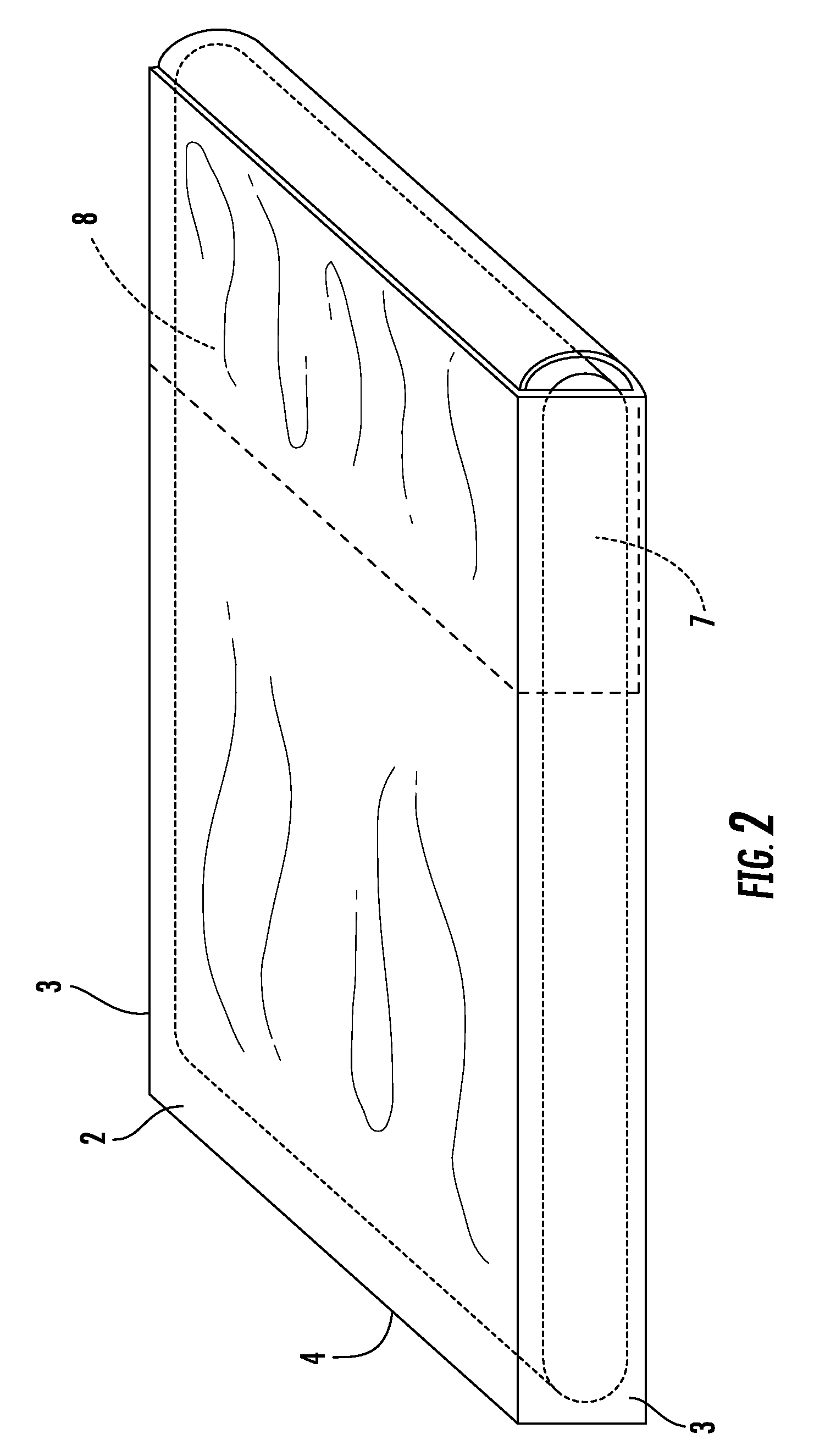

[0024]As is best depicted in FIG. 3, the top panel comprises a central portion which is rectangular in shape and having a width “b” and length “a” and a flap portion which is also rectangular in shape and has a width “d” and length “c”. As may be appreciated the length of the flap portion is perpendicular to the length of the central portion. Both portions together form an integral T-shaped fabric panel. Length “a” is approximately the length of the mattress to be covered plus the thickness of the mattress to be covered. Length “b” is approximately the width of the mattress to be covered. Length “d” is a sufficient length such that when the flap is tucked into the underside of the mattress, between the mattress an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com