Vertical guide mechanism of stone sawing machine

A vertically oriented, stone sawing machine technology, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems affecting the structural stability of the stone sawing machine, the accuracy of stone breaking and cutting, and the poor sliding effect of up and down. Replacement process and maintenance costs, reduced transportation costs, and the effect of avoiding noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

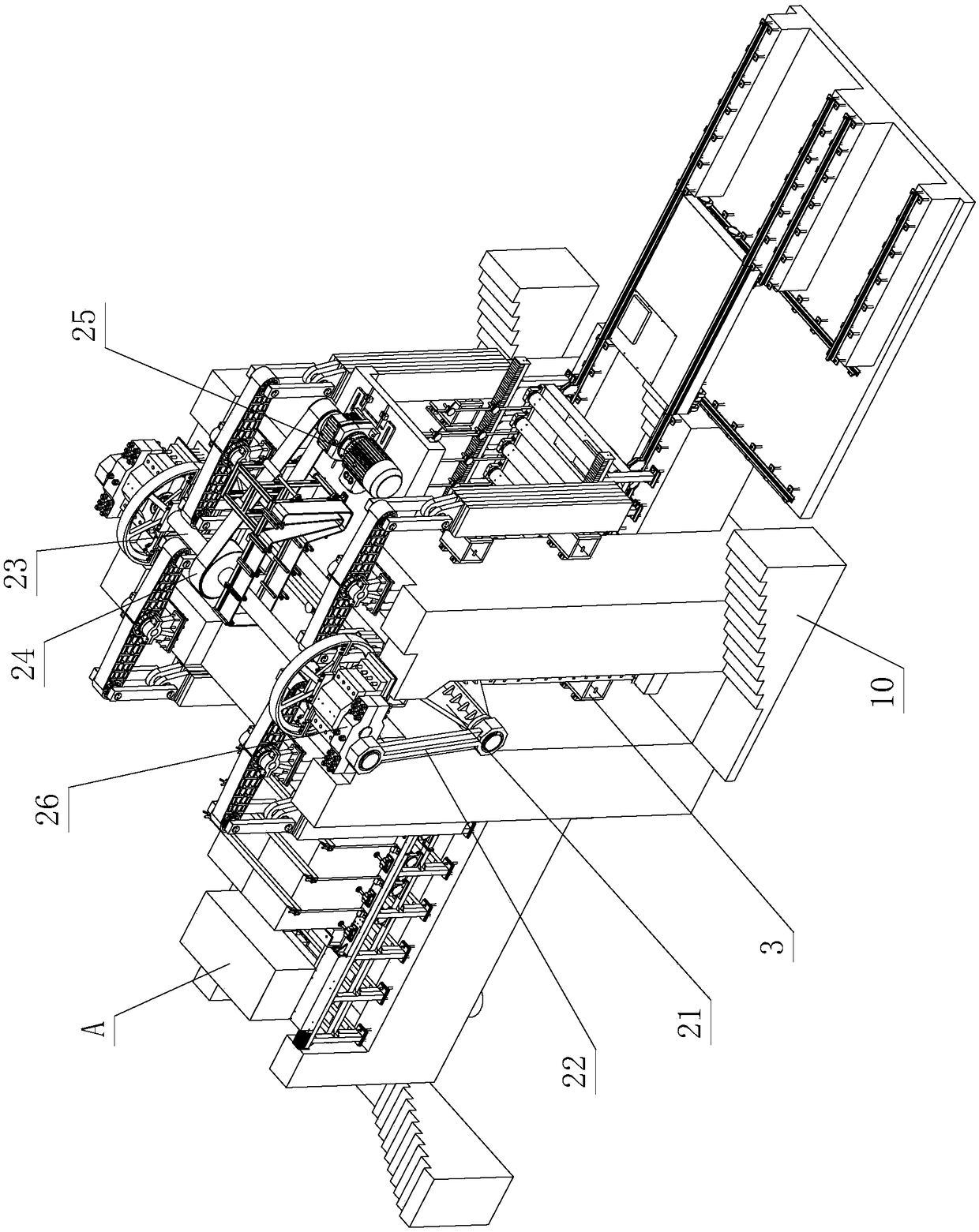

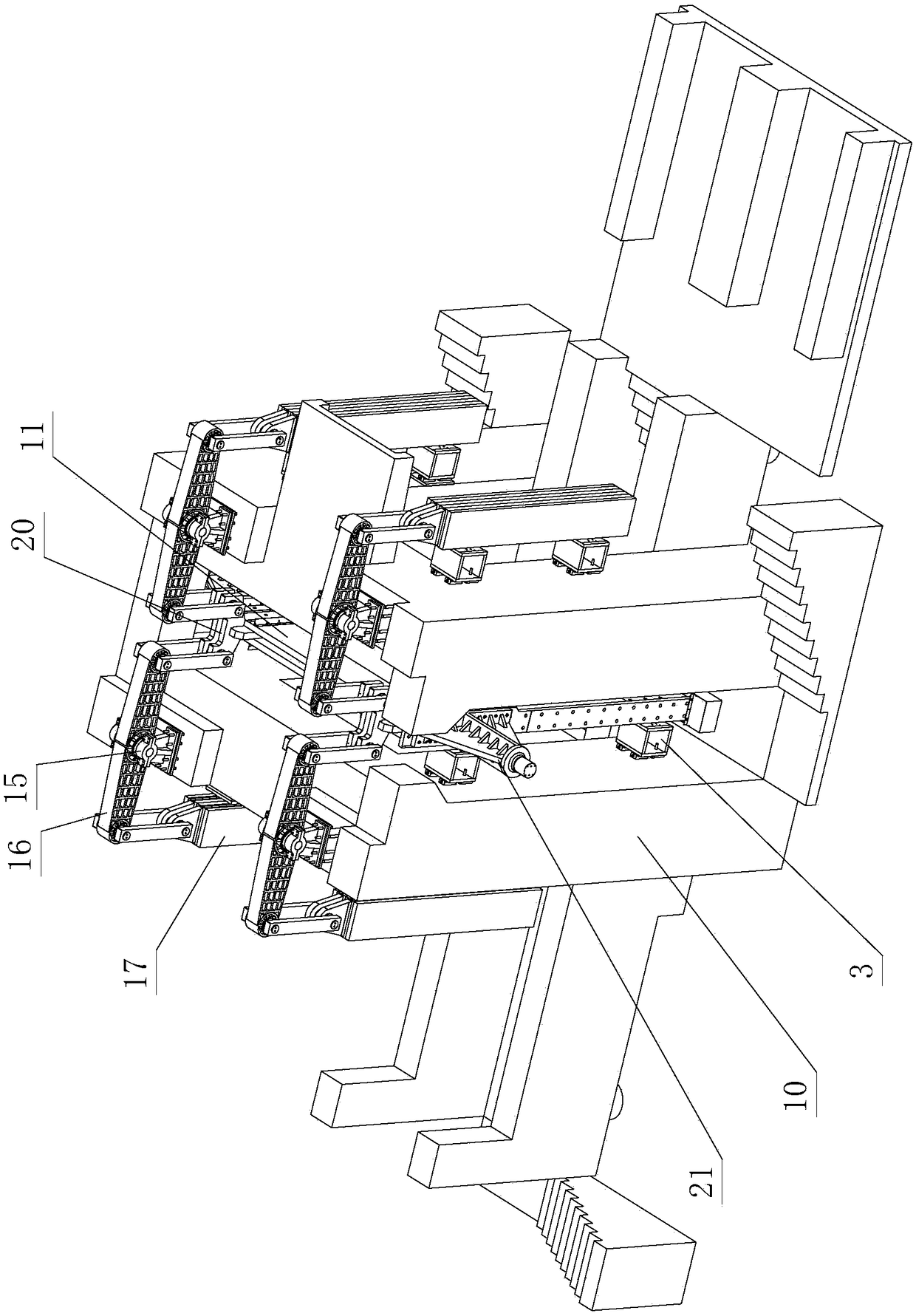

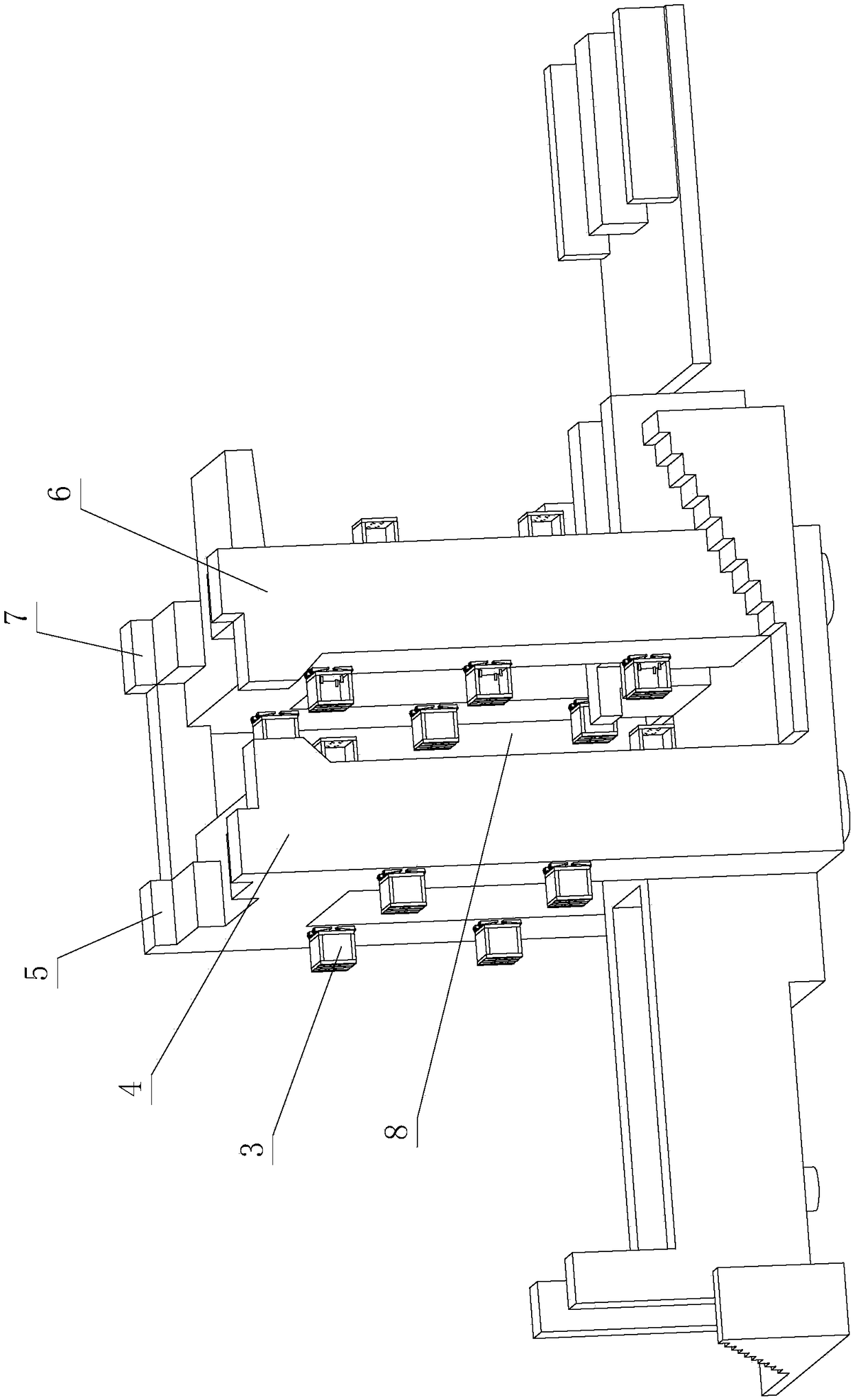

[0032] see Figure 1-Figure 9 , the vertical guiding structure of the stone sawing machine includes a foundation 10 and a stone sawing device arranged on the foundation 10, a stone sawing driving device, a stone sawing power auxiliary device, and a stone pushing device A, and the stone sawing device includes a saw frame and a saw blade, The saw frame is a combination, and a hollow part 1 is arranged in the middle position, and the saw blade is vertically arranged on the hollow part 1, and the saw frame, the stone saw driving device and the saw stone power auxiliary device are mutually driven and connected; wherein, the saw frame and the foundation 10, and / or between the stone-sawing power auxiliary device and the foundation 10, a vertical guide assembly is also arranged; the saw frame reciprocates vertically up and down through the cooperation of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com