Method for encapsulating permanent magnets of a rotor of a generator and rotor of a generator

a technology of permanent magnets and rotors, which is applied in the direction of electric generator control, magnetic circuit rotating parts, magnetic circuit shape/form/construction, etc., can solve the problems of weakening the bond between rotors and magnets, serious damage to generators, and complicated means for retaining magnets in rotors, etc., to achieve the effect of facilitating resin infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

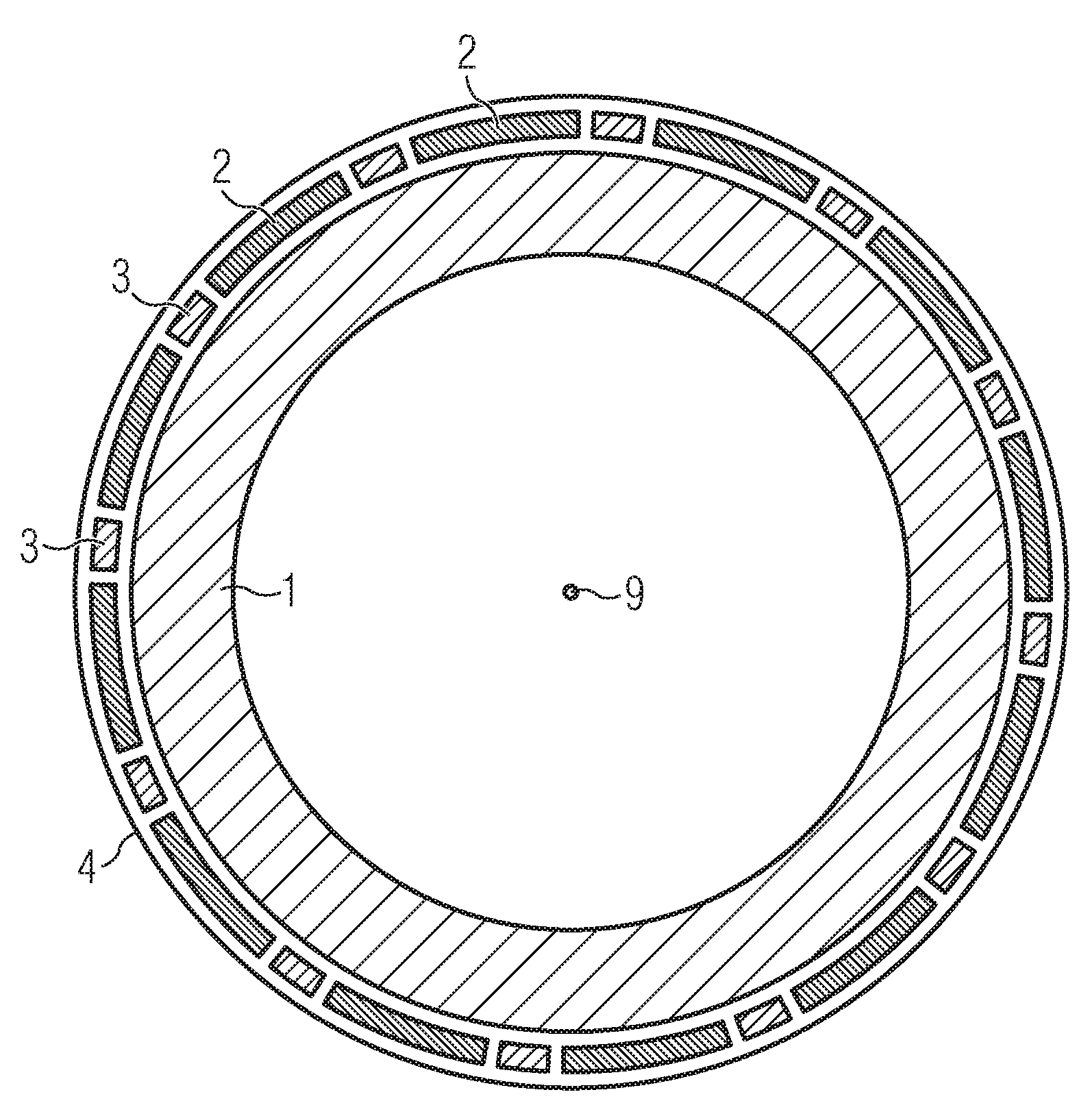

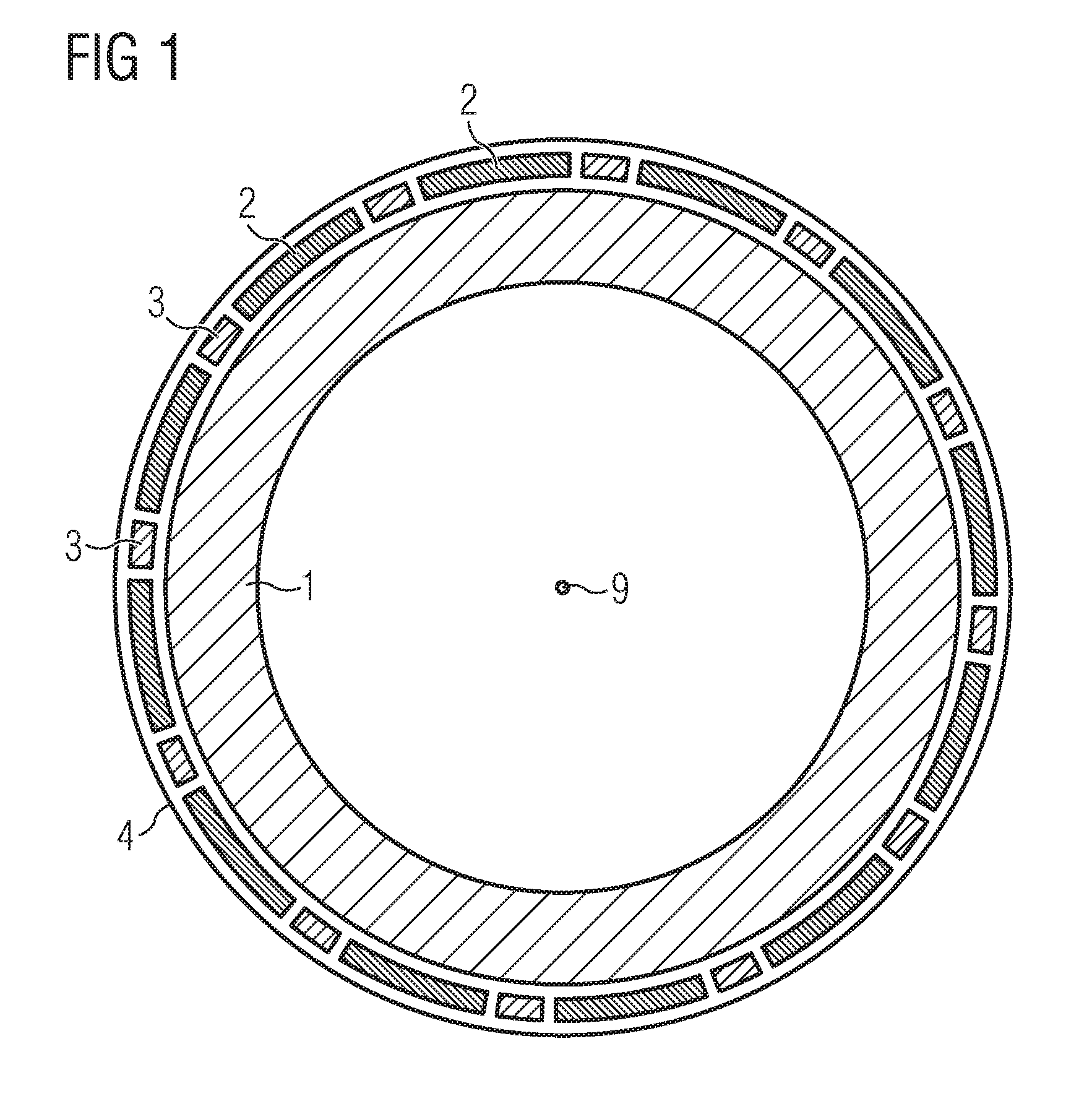

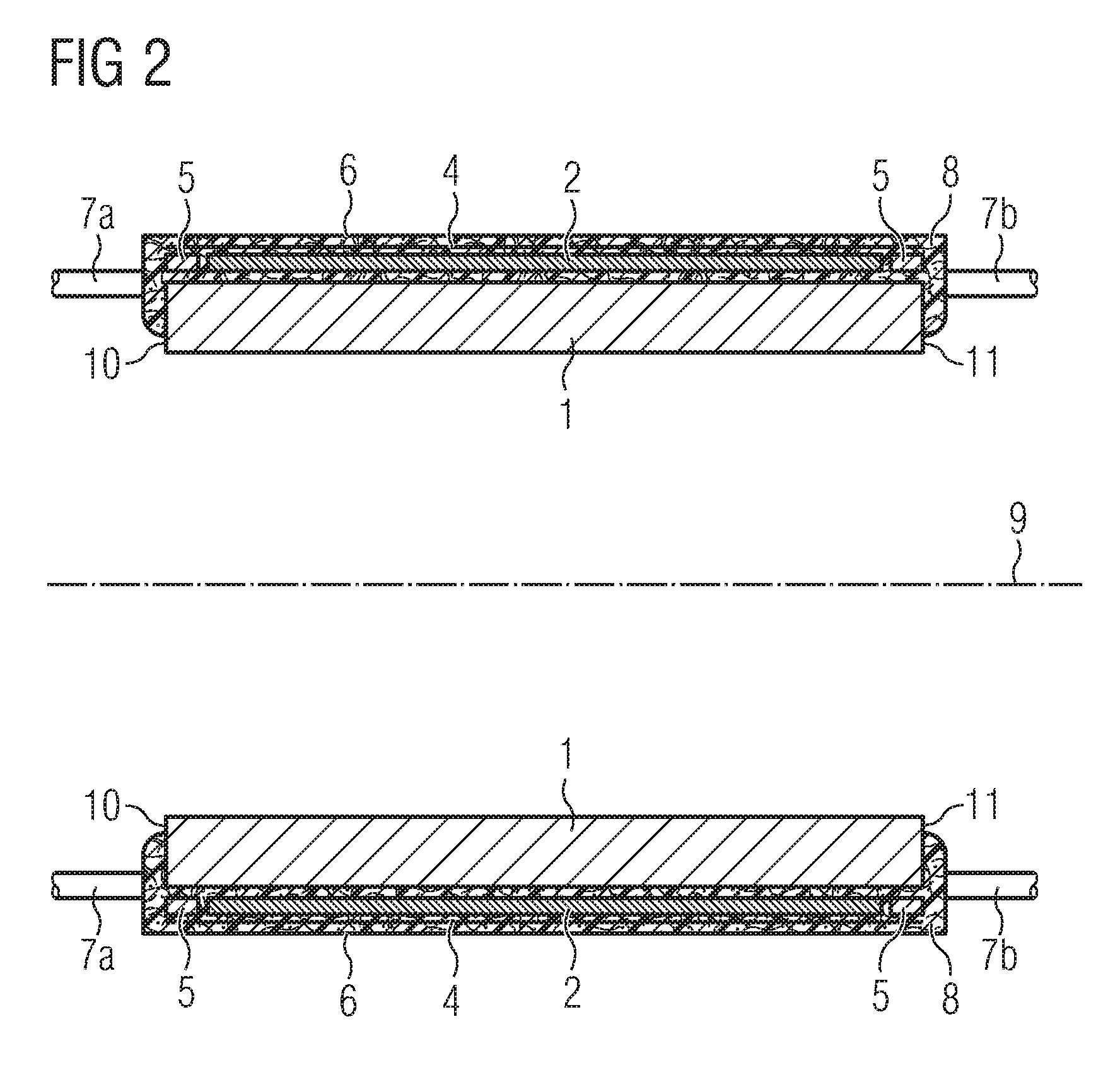

[0032]An embodiment of the present invention will now be described with reference to FIGS. 1 and 2. FIG. 1 schematically shows an inventive rotor of a generator in a sectional view perpendicular to the rotation axis 9. The inventive rotor comprises a rotor yoke 1, permanent magnets 2, spacers 3, and a thin sheet of non-magnetic material 4. Some details, like the rotor shaft and spokes, have been omitted in FIG. 1 and FIG. 2.

[0033]The rotor yoke 1 has a cylindrical shape. The permanent magnets 2 are placed on the outside of the rotor yoke 1. The spacers 3, which are made of a non-magnetic material, are placed between the magnets 2 such that the magnets 2 are maintained at regular angular distances.

[0034]During the assembly the magnets 2 are fixed in their positions by the magnetic forces and the spacers 3 are pressed into the openings between the magnets 2. Alternatively, a fast curing adhesive can be used to affix the magnets 2 and / or the spacers 3. A thin sheet 4 of non-magnetic ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| magnetic forces | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com