Blasting air tube with sleeve, and method

a technology of air tubes and air tubes, applied in the direction of blasting cartridges, weapons, weapon components, etc., can solve the problems of random and imprecise positioning, requiring tedious loading requirements, and inaccurate positioning of air tubes in a column of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

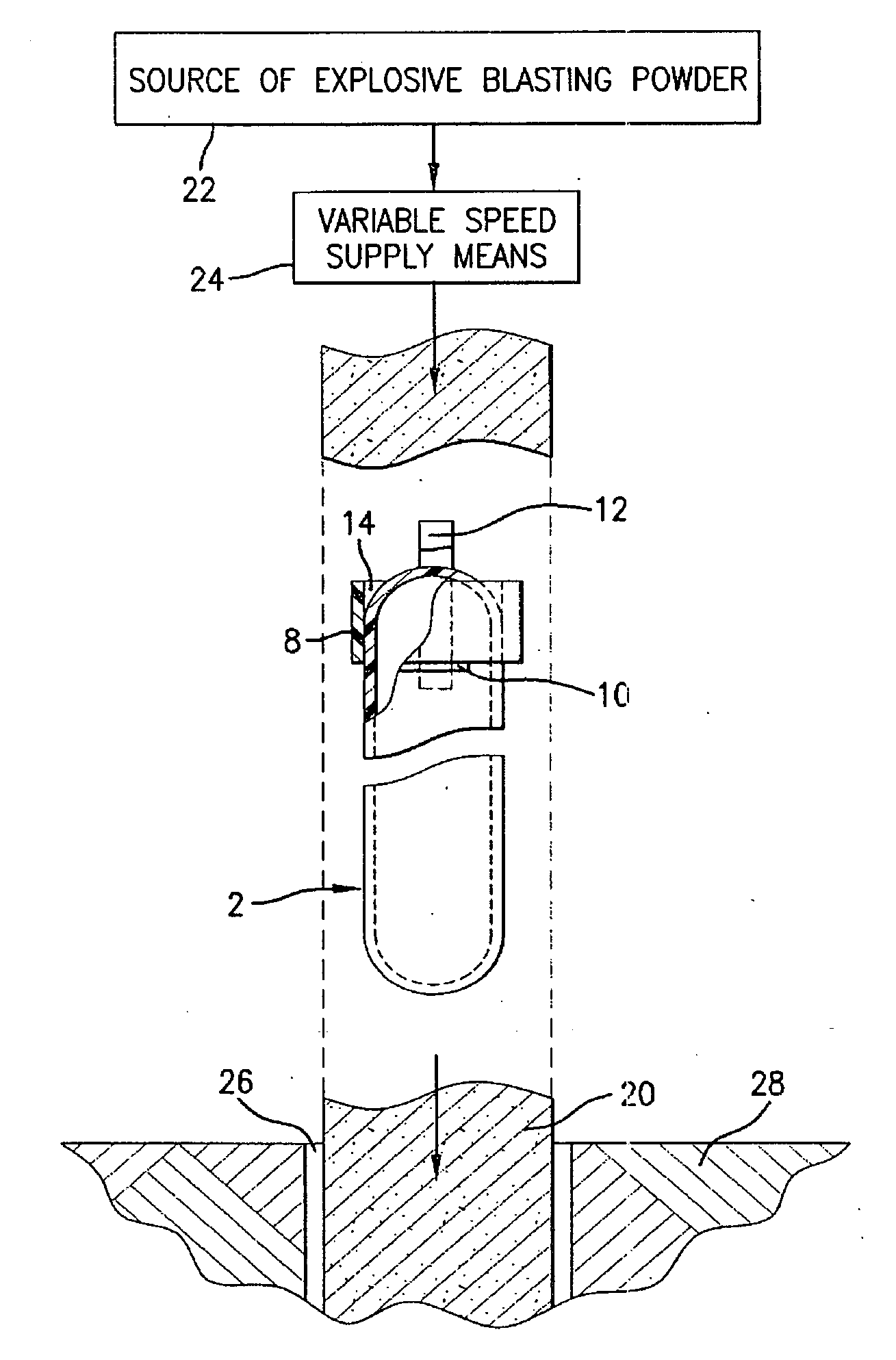

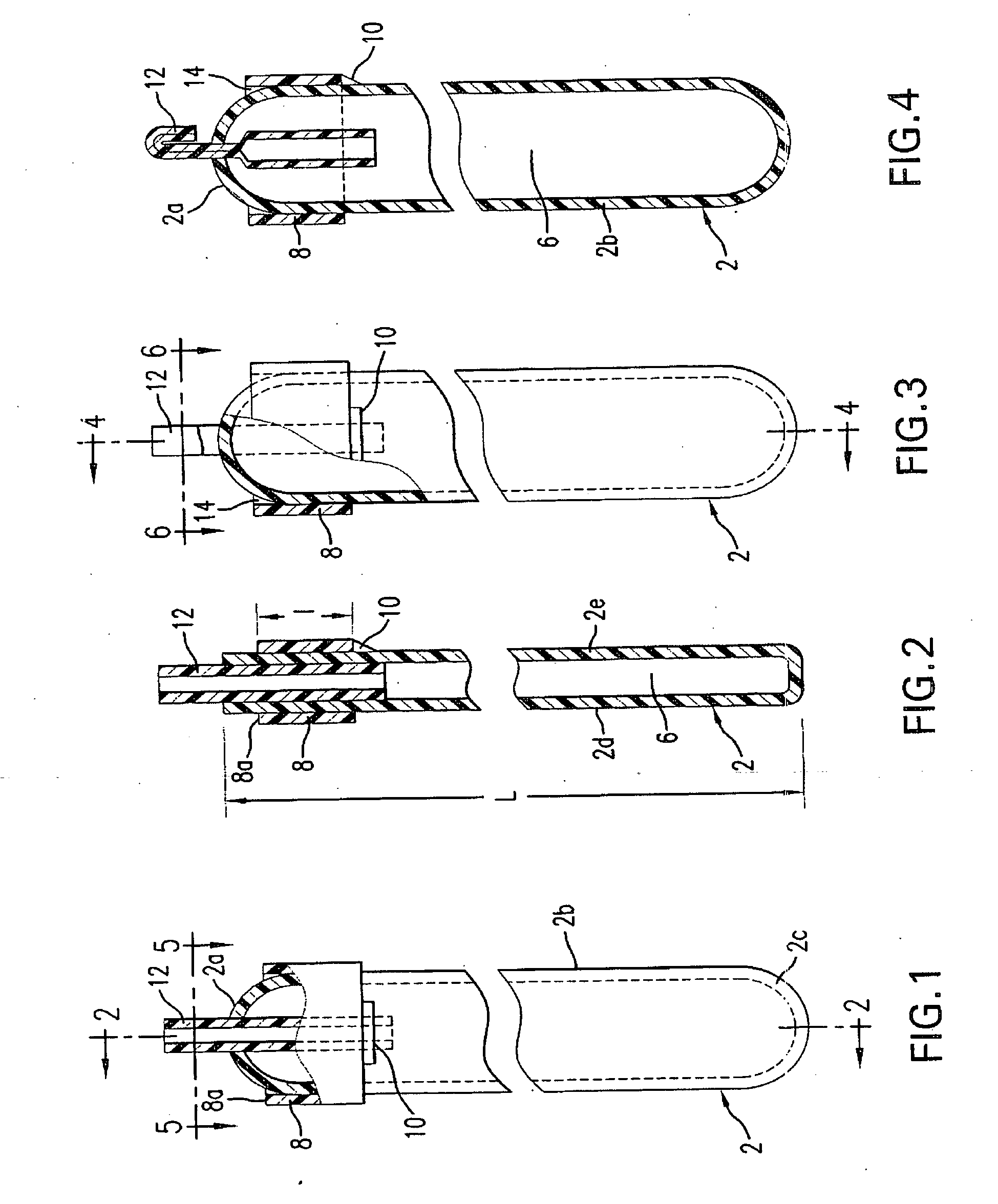

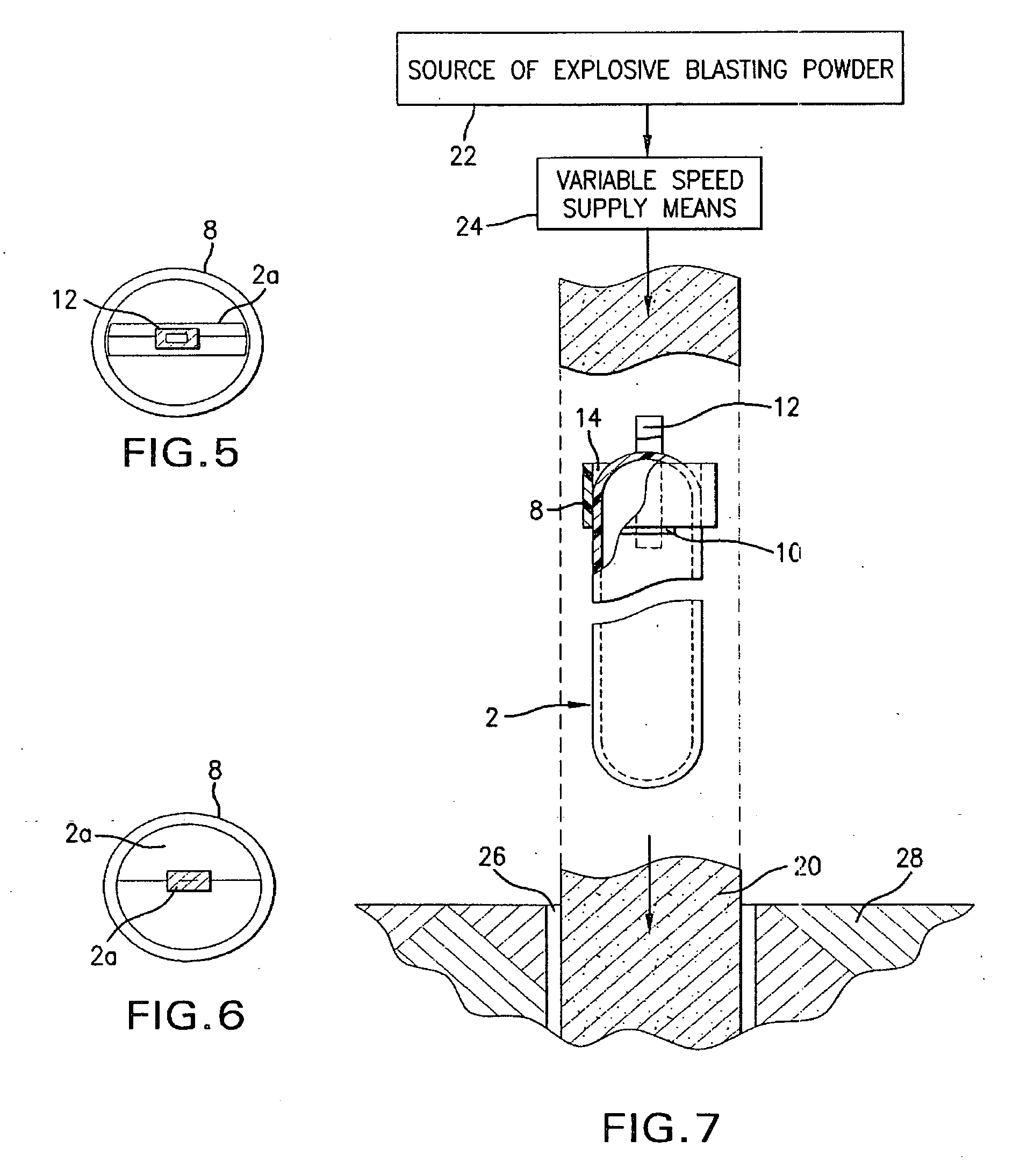

[0021]Referring first more particularly to FIGS. 1 and 2, the air tube 2 is illustrated in the collapsed flat condition and includes an upper end portion 2a, a vertically arranged intermediate portion 2b, and a lower end portion 2c. Prior to the introduction of air into the chamber 6 defined between the parallel air tube side walls 2d and 2e, the upper and lower ends of the air tube have a generally arch-shaped configuration. As shown in FIG. 1. In accordance with a characterizing feature of the present invention, a tubular sleeve member 8 is arranged concentrically about the air tube upper end portion 2a, which sleeve in the collapsed condition of FIGS. 1 and 2 is flat and is secured to the air tube side wall 2e by a fastening strip 10, such a heat seal seam, an adhesive strip, an adhesive layer between the sleeve member and the air tube, or the like. Preferably the upper edge 8a of the sleeve member is even with the adjacent edge of the arch-shaped end portion 2a, as shown in FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com