Oxygen Scavenging Compositions and Packaging Comprising Said Compositions

a composition and oxygen scavenging technology, applied in the direction of synthetic resin layered products, containers preventing decay, explosives, etc., can solve the problems of narrow narrow restriction of the choice of base polymer resin and add cost to the layer, and achieve the effect of eliminating haz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

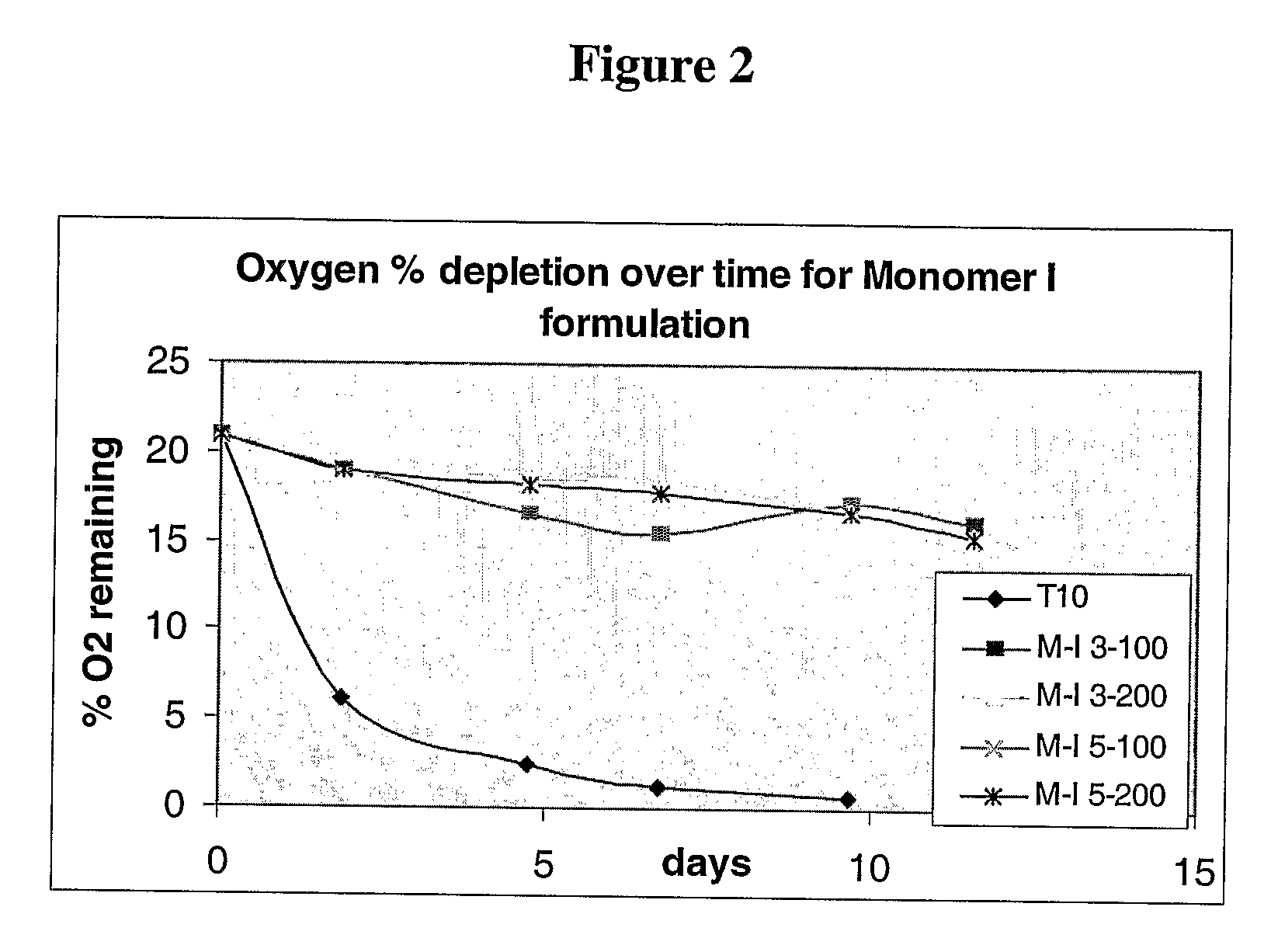

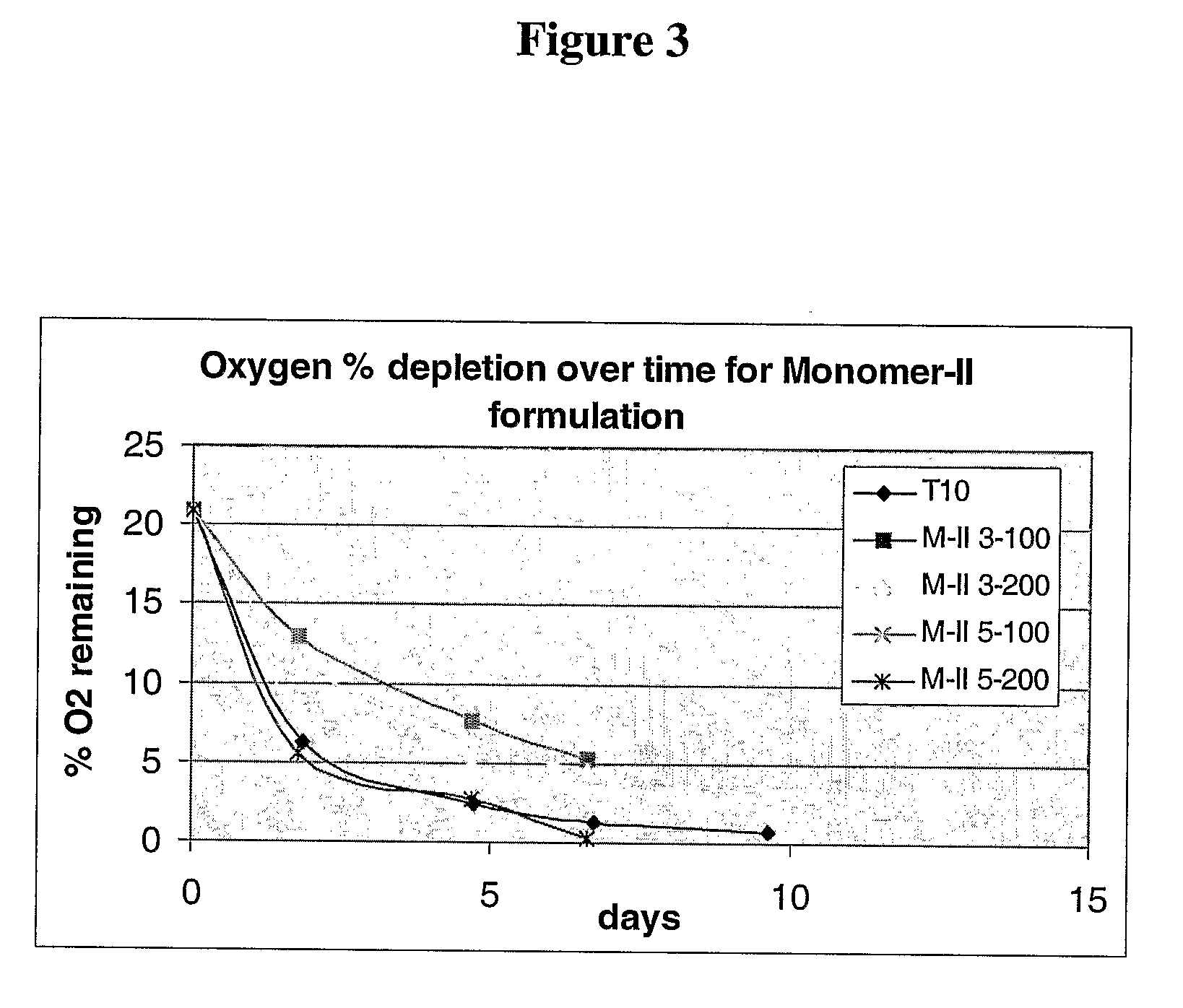

[0160]Extruded strips were prepared using a bench-top Killion extruder (with typical extruder output rate between 8-10 lbs / hour) for evaluating oxygen scavenging potential using Oxy-Sense™ for Monomer-I and Monomer-II. The temperature profile across different extruder zones used was typical to that used for PET (about 525° F.). Extruded films were cut into thin strips and about 2 g samples for each formulation were sealed into 22 mL glass vials and stored at elevated temperature (70° C.). The % oxygen depletion inside the vials over time was monitored using commercially available Oxy-Sense™ instrument. Different formulations and their respective code names are given below:

[0161]1. PET+3% 6007+100 ppm Co carboxylate powder (Code: T10)

[0162]2. PET+3% Monomer-I+100 ppm Co carboxylate powder (Code: M-I 3-100)

[0163]3. PET+3% Monomer-I+200 ppm Co carboxylate powder (Code: M-I 3-200)

[0164]4. PET+5% Monomer-I+100 ppm Co carboxylate powder (Code: M-I 5-100)

[0165]5. PET+5% Monomer-I+200 ppm C...

example 2

[0172]Preforms were injection molded on a 2 cavity Husky LX160 PET injection molding machine. Preforms were made with the following formulations:

[0173]Heat Wave™ (Voridian) PET+3% Monomer-I+75 ppm Co carboxylate powder

[0174]Heat Wave PET+3% Monomer-II+75 ppm Co carboxylate powder

[0175]PET, Monomer-I (in powder form) and Cobalt carboxylate mixture (cobalt neodeconate (Co NDA, CAS #27253-31-2) and cobalt propionate (CAS#1560-69-6) mixture with a 20.5% Co metal content) were tumble blended in a bucket and fed into the machine hopper. Actual final composition in the preform was not verified. Bottles were blown on the unit cavity Re-heat and blow lab machine for oxygen transmission rate (OTR) and haze measurement.

Monomer-I Trial Results:

[0176]20 oz bottles were blown form preforms and stored empty at STP conditions prior to testing. Two sets of the empty bottles were mounted on an oxygen permeation measuring device—similar to MoCon Oxtran analyzer. The first set (A) were mounted 2 days a...

example 3

[0180]Preforms were made on Husky LX 160 PET, 2 cavity machine using the following formulation: Vitiva™ PET+3% N,N′ Bis (phenylmethyl) hexane diamide (Monomer-I)+75 ppm Co. Vitiva PET and Monomer-I powder were tumble blended in a bucket and fed into the machine hopper. Cobalt-NDA dispersed in a liquid hydrocarbon carrier, was introduced using a ColorMatrix brand positive displacement pump. Actual final composition in the preform was verified by performing Nitrogen and ICP analysis Bottles were blown on a unit cavity 16 oz blow mold using a Sidel SBO-1 machine. Bottles were blown and were mounted on an oxygen permeation measuring device—similar to MoCon Oxtran analyzer—13 days after manufacture.

Trial Results:

[0181]The graph in FIG. 6 shows the OTR performance.

[0182]As cab be seen from the graph in FIG. 6, some scavenging is evidenced. In order to determine the scavenging potential, samples from the side wall of the container were sealed into a 20 mL vial and decrease in oxygen % over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com