Reducing tire rolling resistance through pre-heating

a technology of preheating and tire rolling resistance, applied in the field of tires, can solve the problems of non-adaptive solutions of conventional tires, and achieve the effects of reducing the rolling resistance of tires, optimal tire performance, and improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

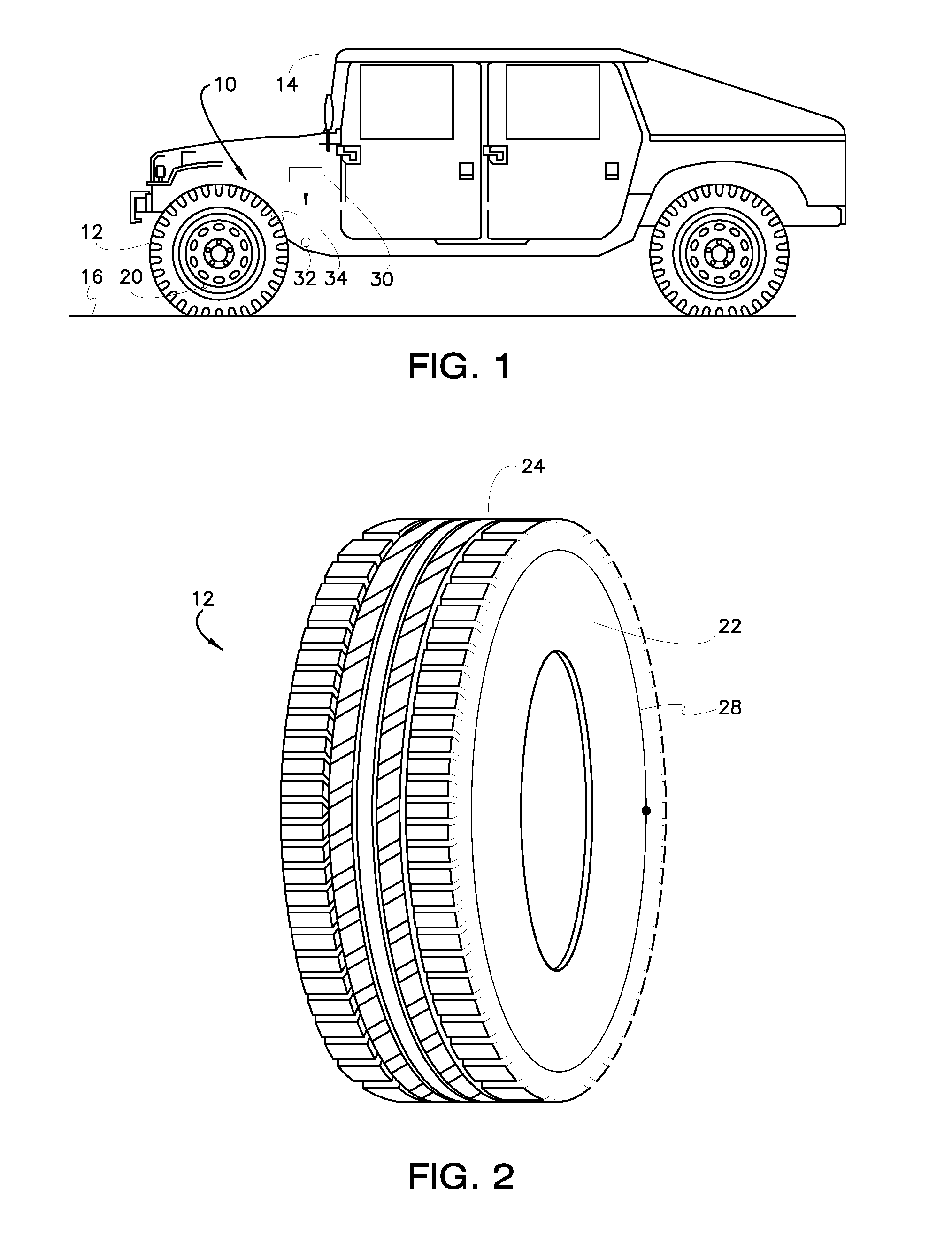

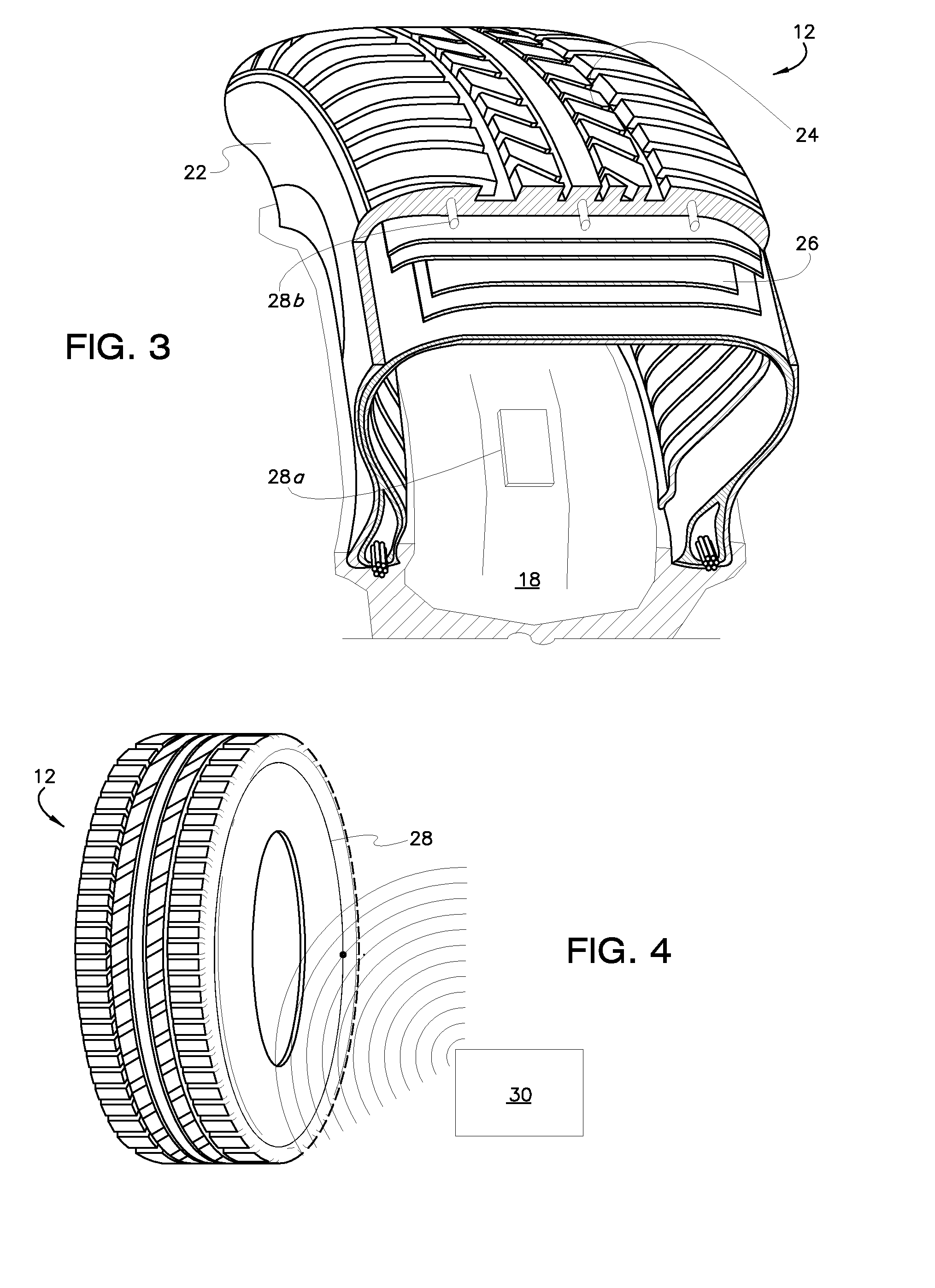

[0014]The present invention generally concerns a system 10 for and method of reducing the rolling resistance of a tire 12 through pre-heating. That is to say, in the present invention, the tire 12 is heated prior to use, and is particularly suited to prevent traditional cold state rolling resistance concerns. As such, a solution is presented that is responsive to the afore-mentioned concerns regarding the effect of rolling resistance on fuel (e.g., electric charge) economy. The invention is described and illustrated herein with respect to an automotive vehicle 14 (e.g., motorcycle, car, truck, SUV, all-terrain vehicle, etc.) that travels upon a surface 16; however, it is certainly appreciated that the advantages and benefits thereof could be used in other applications, such as bicycles and the like.

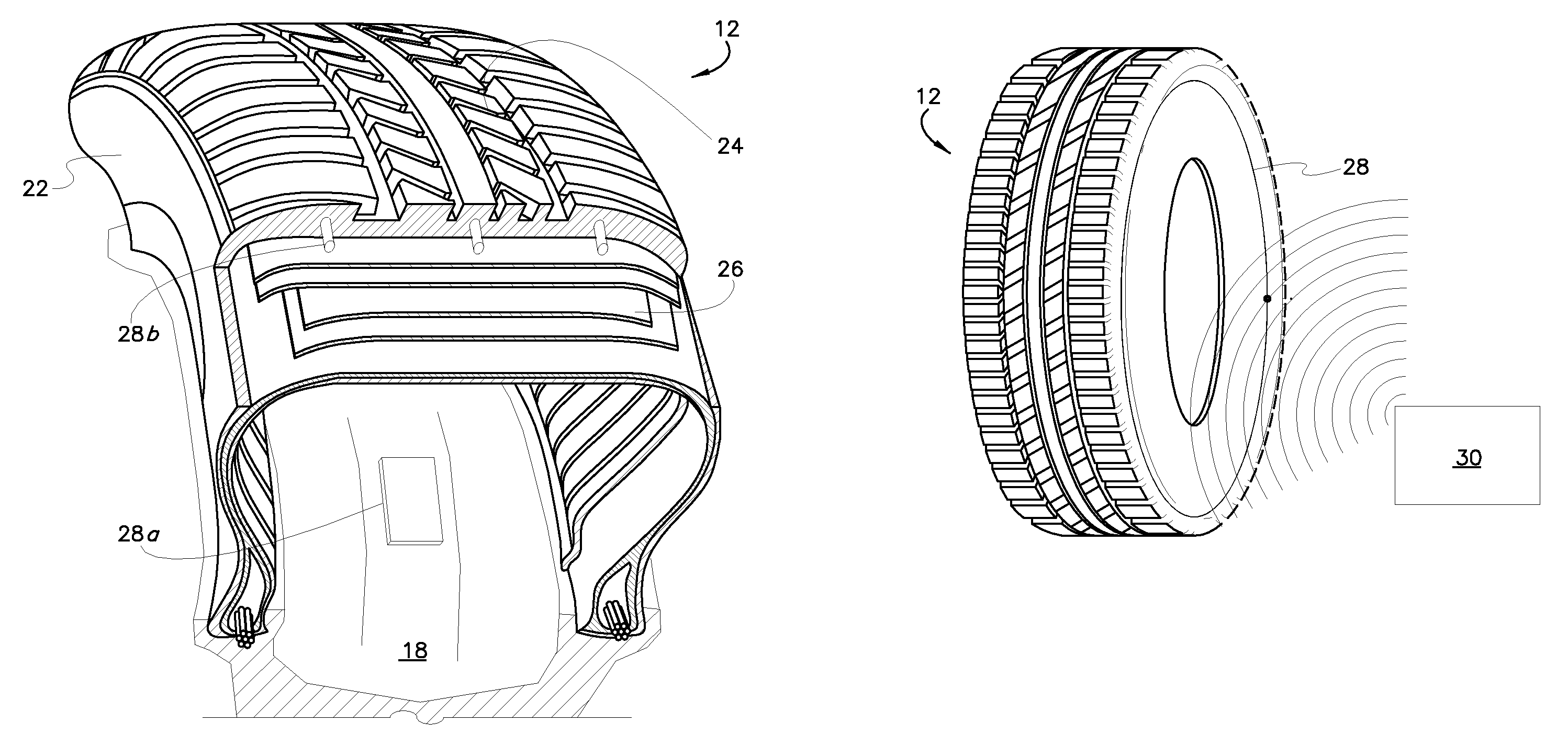

[0015]As best shown in FIGS. 2 and 3, the inventive implements of the system 10 are adapted for use with an otherwise conventional elastomeric (e.g., synthetic and / or natural rubber) tire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com