Rifle with sling and clip and method for slinging a rifle with a clip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

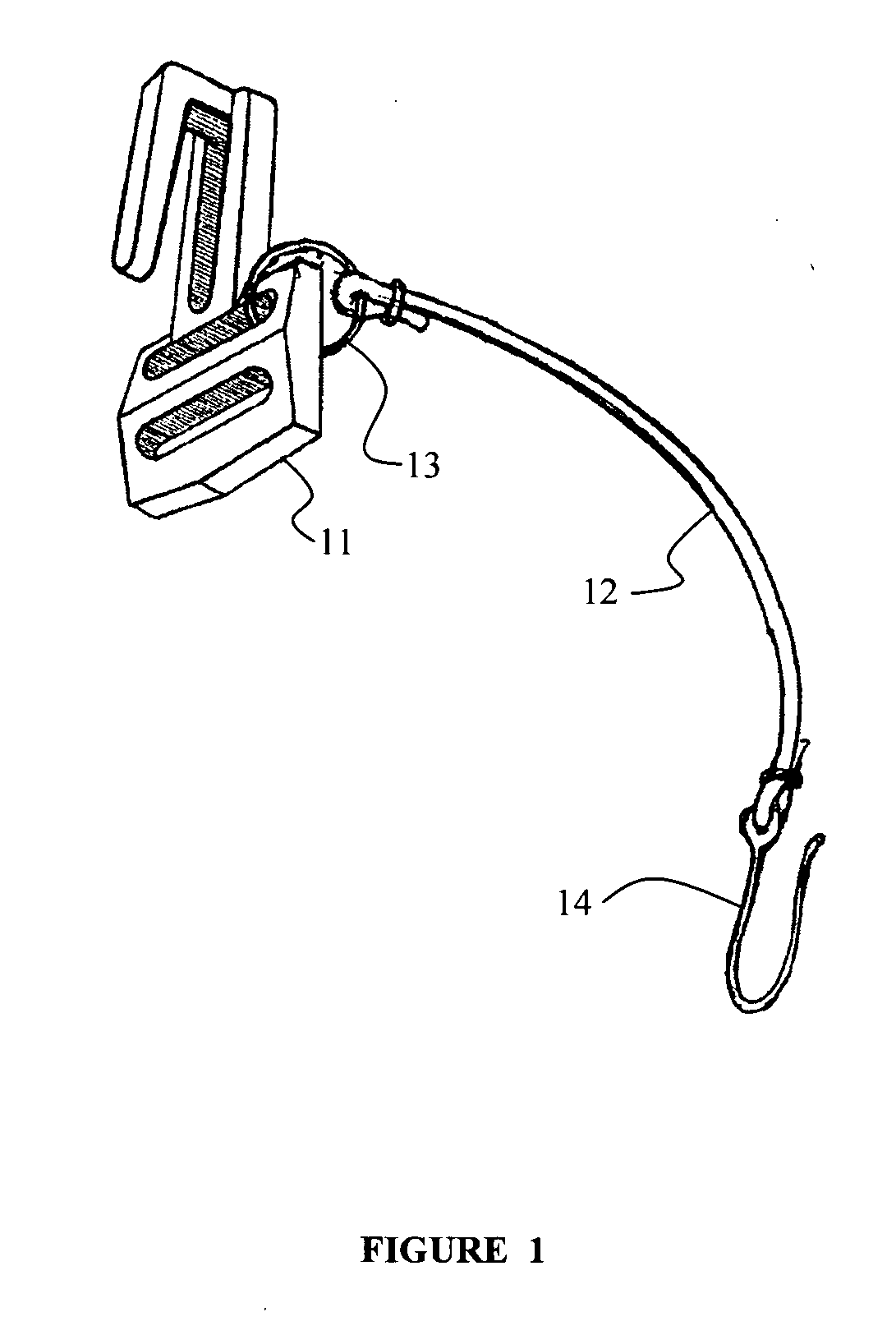

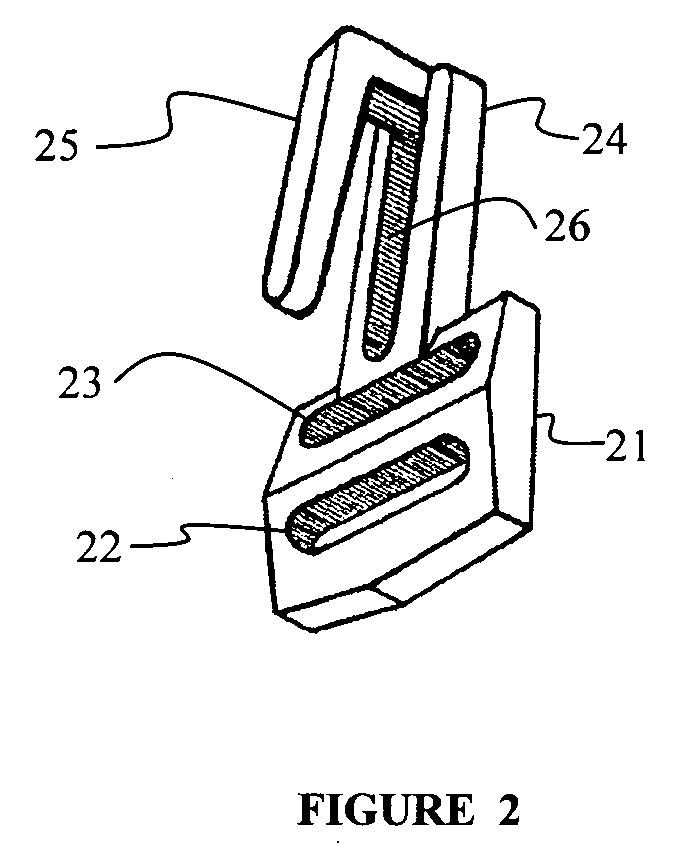

[0017]In the preferred embodiment, the clip is made of some sort of plastic. The plastic can be any inexpensive and durable substance like nylon of polypropylene. The clip is manufactured using plastic injection molding equipment. Such plastics have the advantage that they are cheap, reliable, sturdy, and weatherproof. Alternatively, the clip can be made of metal, such as aluminum, titanium, or some alloy.

[0018]The clip in FIG. 2 is made of a solid piece of plastic. It has a slotted end 21 with slots 22 and 23. The slots can accommodate a strap or sling. The clip also has a hooked end 24 with a hook 25. A slot 26 underneath the hook 25 is also shown. The slot is not actually necessary for the function of the clip, but assists in the manufacture of the clip. With the slot 26, the clip can be made with two-piece mold. Without the extra slot, the clip can be made with a three-piece mold.

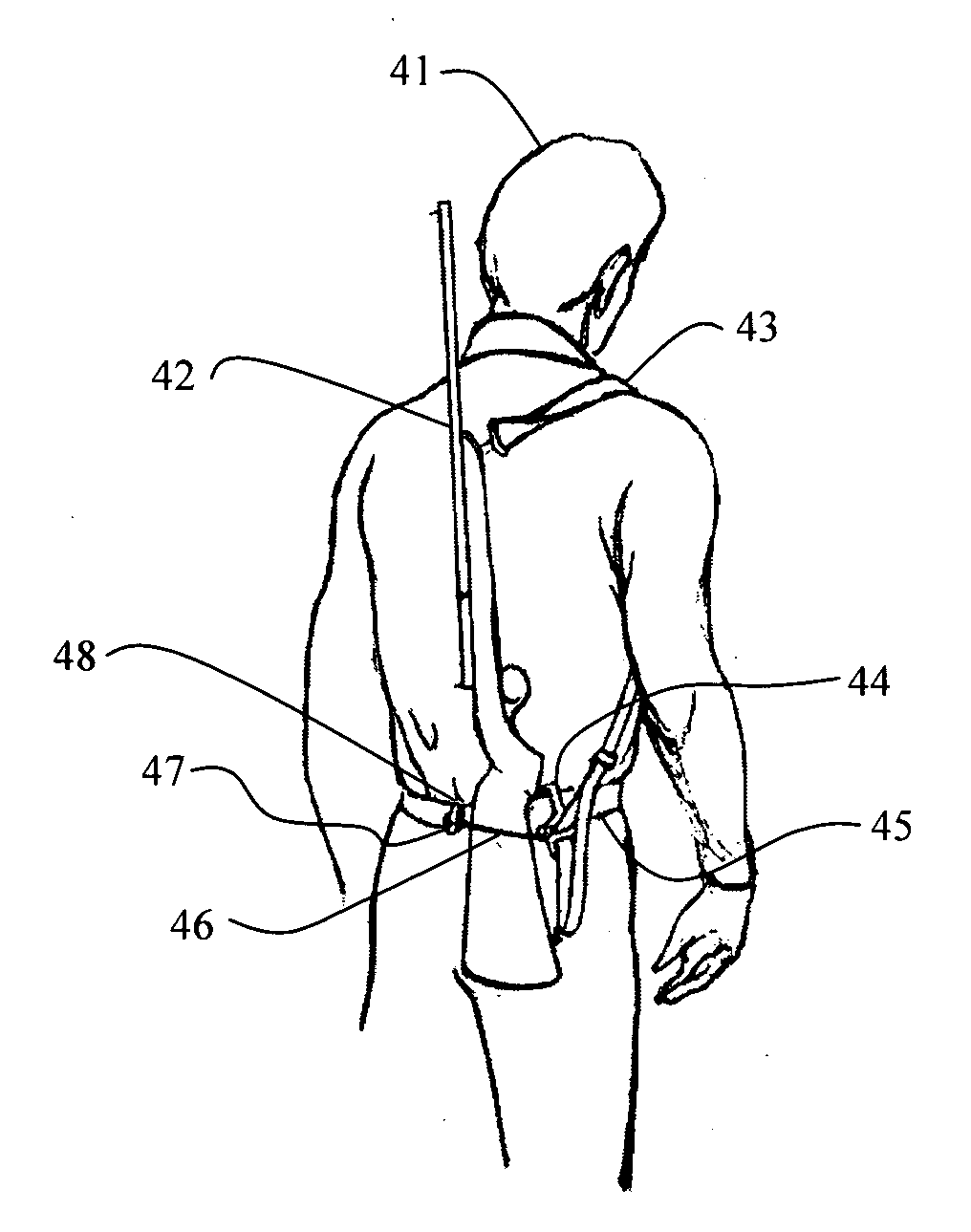

[0019]The hook on the clip is simple, straight, and snag-free. A hunter or soldier may have to use h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com