Sheet discharging device and image forming apparatus including the sheet discharging device

a technology of discharging device and image forming apparatus, which is applied in the direction of electrographic process apparatus, thin material handling, instruments, etc., can solve the problems of extreme deterioration of sheet dischargeability, and achieve the effect of improving the discharged sheet loading performance and preventing uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

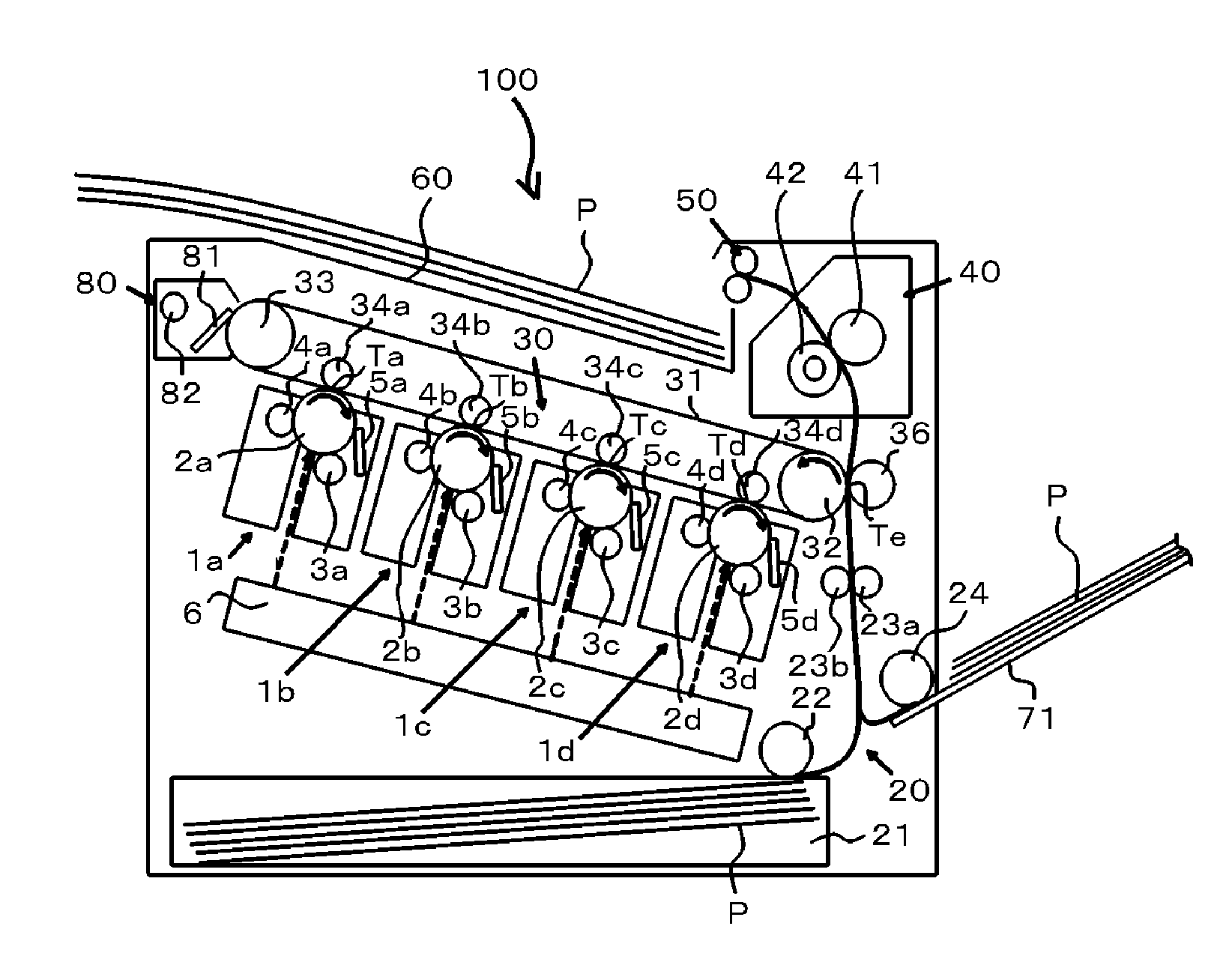

[0030]FIG. 1 is a cross-sectional view illustrating a configuration of an image forming apparatus 100 according to the first embodiment of the present invention. The image forming apparatus 100 is a color image forming apparatus using an electrophotographic image forming process.

[0031]As illustrated in FIG. 1, the image forming apparatus 100 includes an image forming portion 1a for forming a yellow image and an image forming portion 1b for forming a magenta image. The image forming apparatus 100 further includes an image forming portion 1c for forming a cyan image and an image forming portion 1d for forming a black image. The image forming apparatus 100 includes those four image forming portions (image forming unit). Those four image forming portions 1a, 1b, 1c, and 1d are arranged in a row at a constant interval. The image forming portions 1a, 1b, 1c, and 1d respectively include drum-type electrophotographic photoreceptor (hereinafter referred to as photosensitive drums) 2a, 2b, 2c...

second embodiment

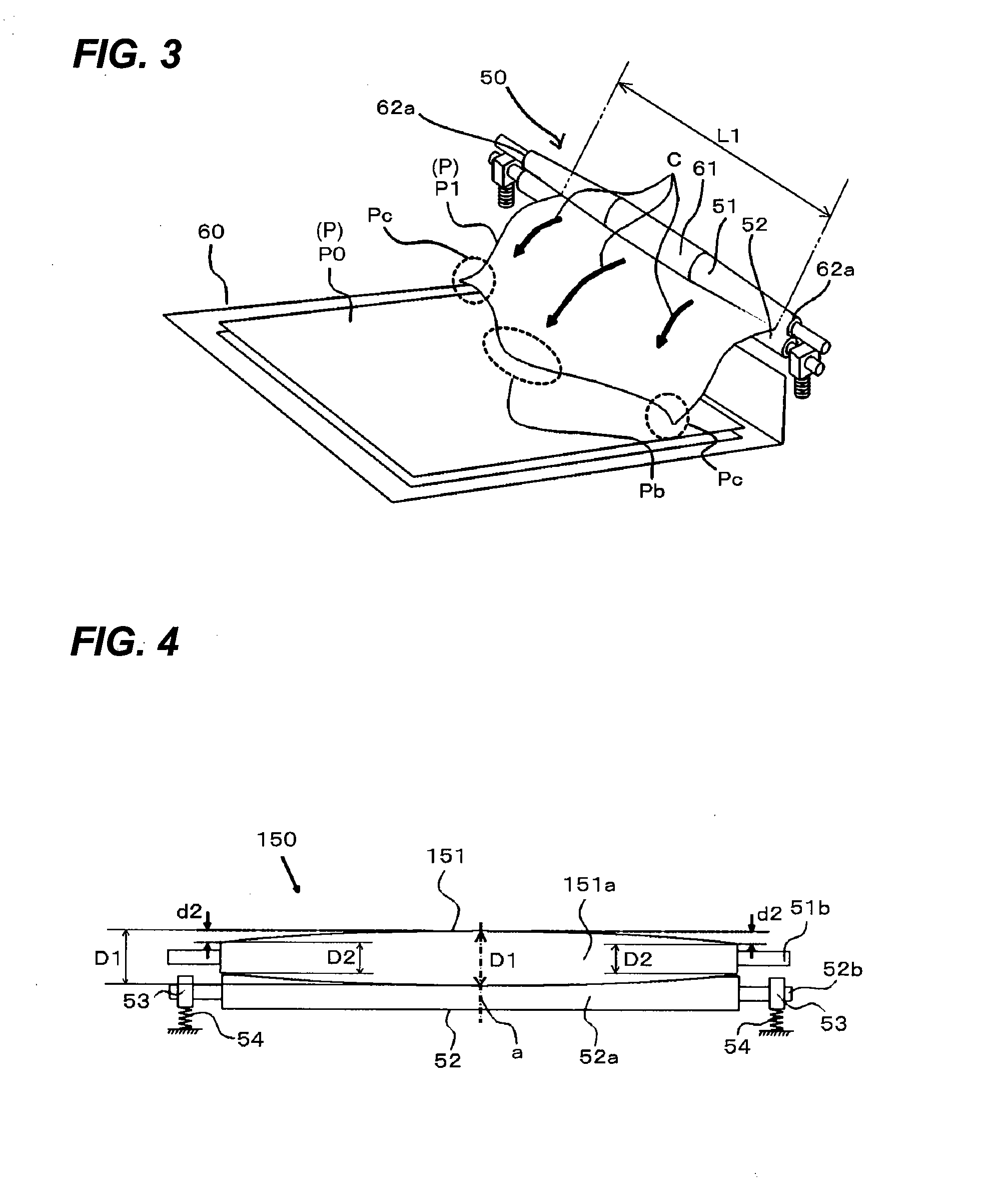

[0059]FIG. 4 is an enlarged side elevational view illustrating a configuration of a sheet discharging unit 150, used in the image forming apparatus according to the second embodiment of the present invention, as viewed from the downstream side in the conveyance direction of the sheet P. The sheet discharging unit 150 is different from the sheet discharging unit 50 of the first embodiment in the use of a sheet discharge drive roller 151 instead of the sheet discharge drive roller 51. In the sheet discharging unit 150, the same components and effects as those in the sheet discharging unit 50 are denoted by the same reference numerals, and the description is suitably omitted. Also in the second embodiment, the image forming apparatus similar to that of the first embodiment can be used, and thus the description of the image forming apparatus is omitted.

[0060]As illustrated in FIG. 4, the sheet discharging unit 150 is constituted of a sheet discharge drive roller 151 and a sheet discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com