Impact Resistant Shingle

a technology of impact resistance and shingle, which is applied in the field of shingle, can solve the problems of cracks that can develop in the lower surface of the shingle, and achieve the effect of resisting cracking and discharging mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

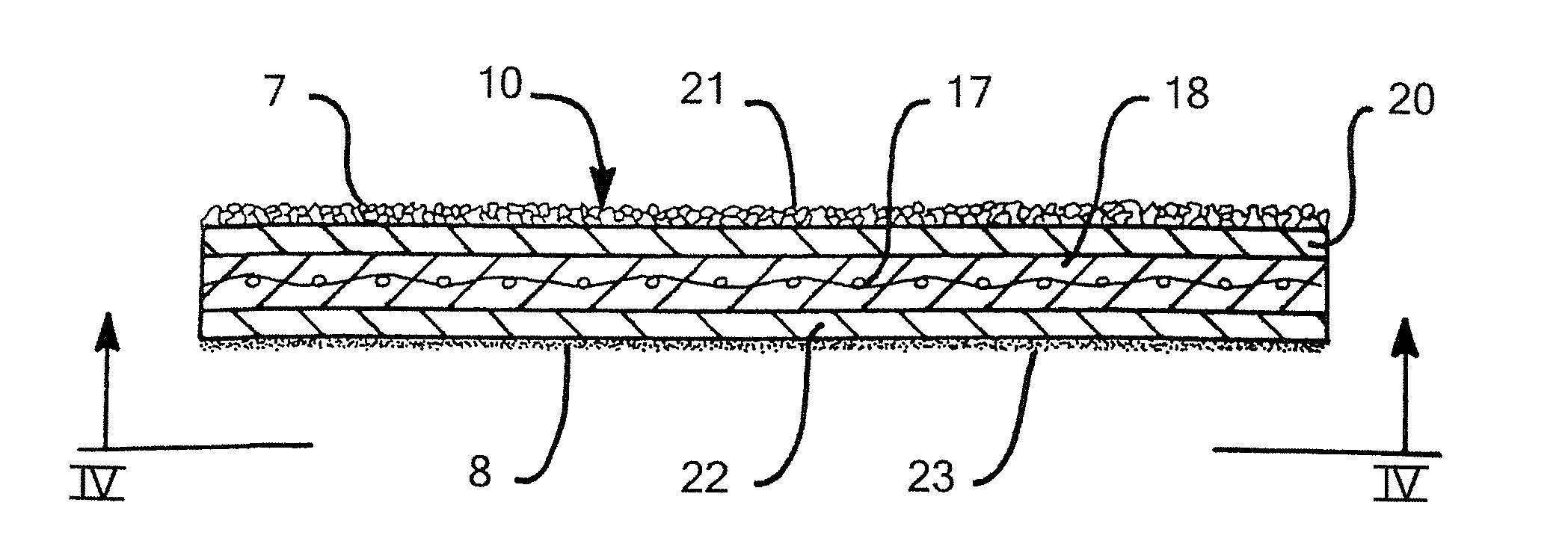

[0023]Referring now to the drawings in detail, reference is first made to FIG. 1, wherein a shingle is shown, generally designated by the numeral 10. The shingle 10 is comprised of an upper headlap portion 11 and lower tab portions 12, with the tab portions being four in number. The various tab portions 12 are spaced apart by slotted openings 13.

[0024]The upper headlap portion 11 is that which is disposed above the upper ends of the slotted openings 14. Left and right edges 15 and 16, respectively, of the shingle 10 have partial cut-outs 15a and 16a, respectively, such that when shingles 10 are aligned left-to-right, portions of slotted openings 15a and 16a will come together forming full slotted openings.

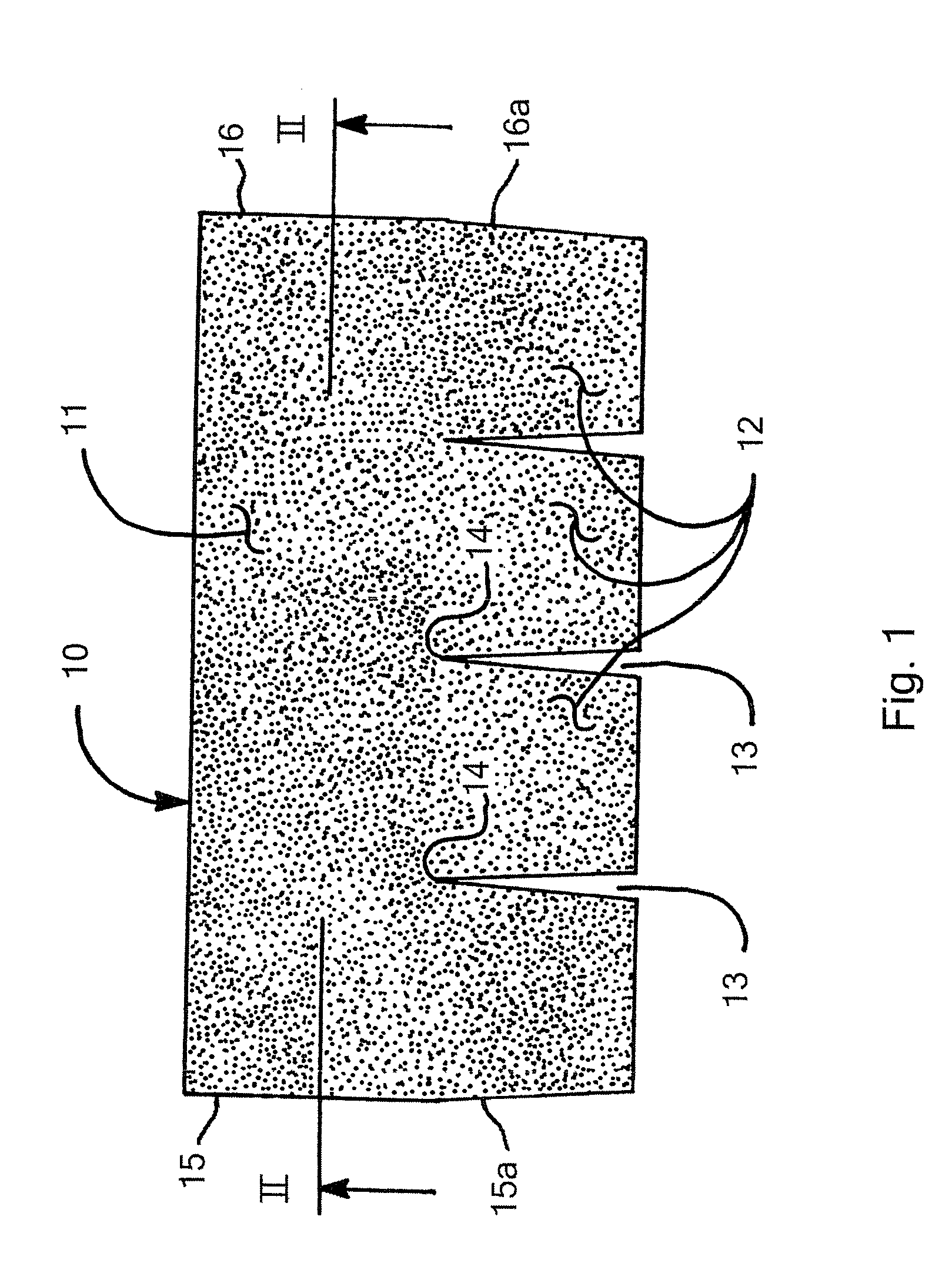

[0025]With reference to the shingle of FIGS. 2 and 2A, the shingle 10 has respective upper and lower surfaces 7, 8 and is comprised of a base mat 17 of preferably fiberglass mat construction, although the same can be comprised of organic mat, or fibered polymeric mat construction (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com