Electric vacuum cleaner

a vacuum cleaner and electric technology, applied in the direction of vacuum cleaners, cleaning equipment, domestic applications, etc., can solve the problems of inability to reduce the effort involved, the suction port portion becomes easily heavy, and the cleaning operation is weary, so as to facilitate the cleaning operation, reduce the burden of cleaning operation, and easily change the direction of the suction port portion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

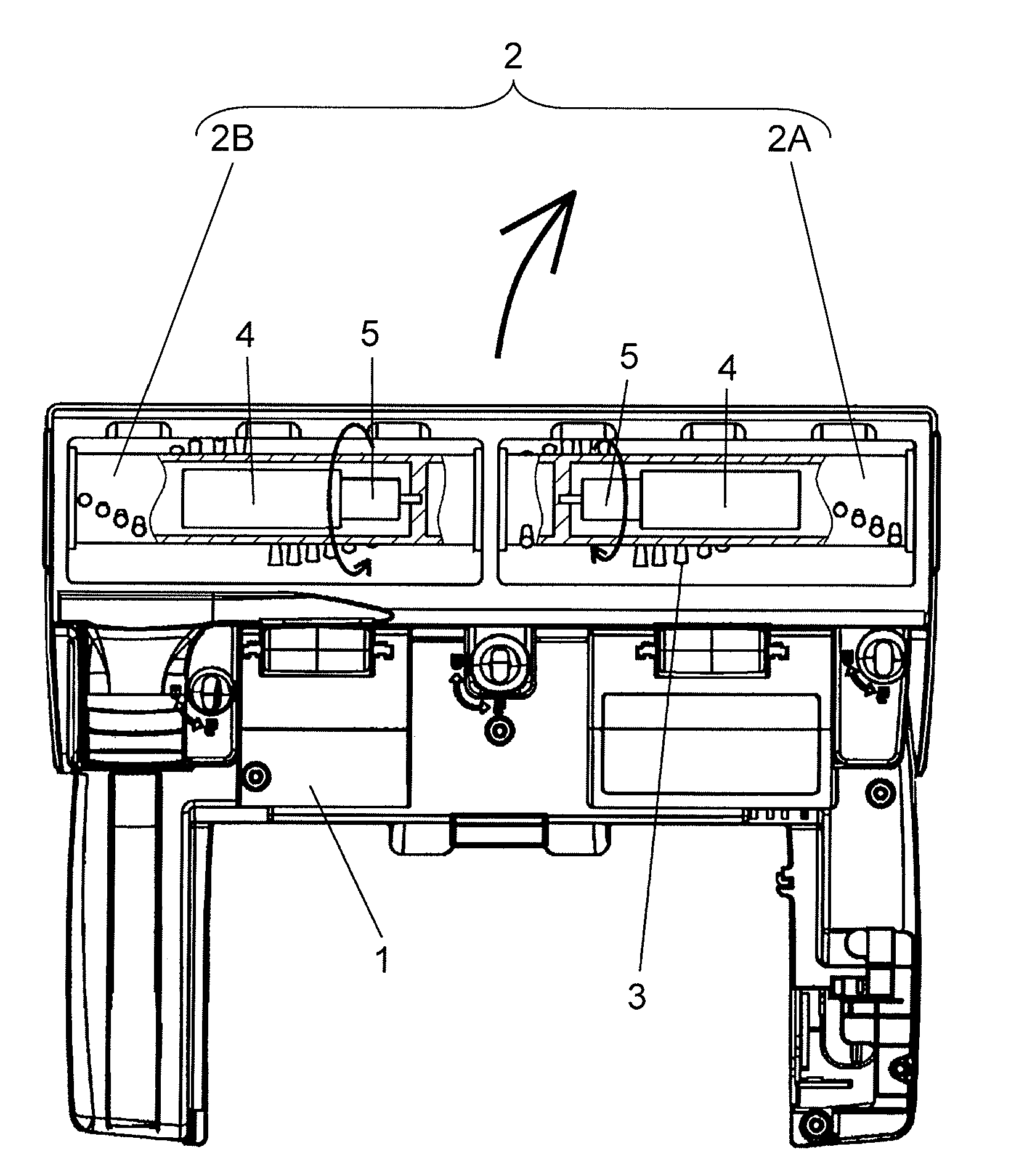

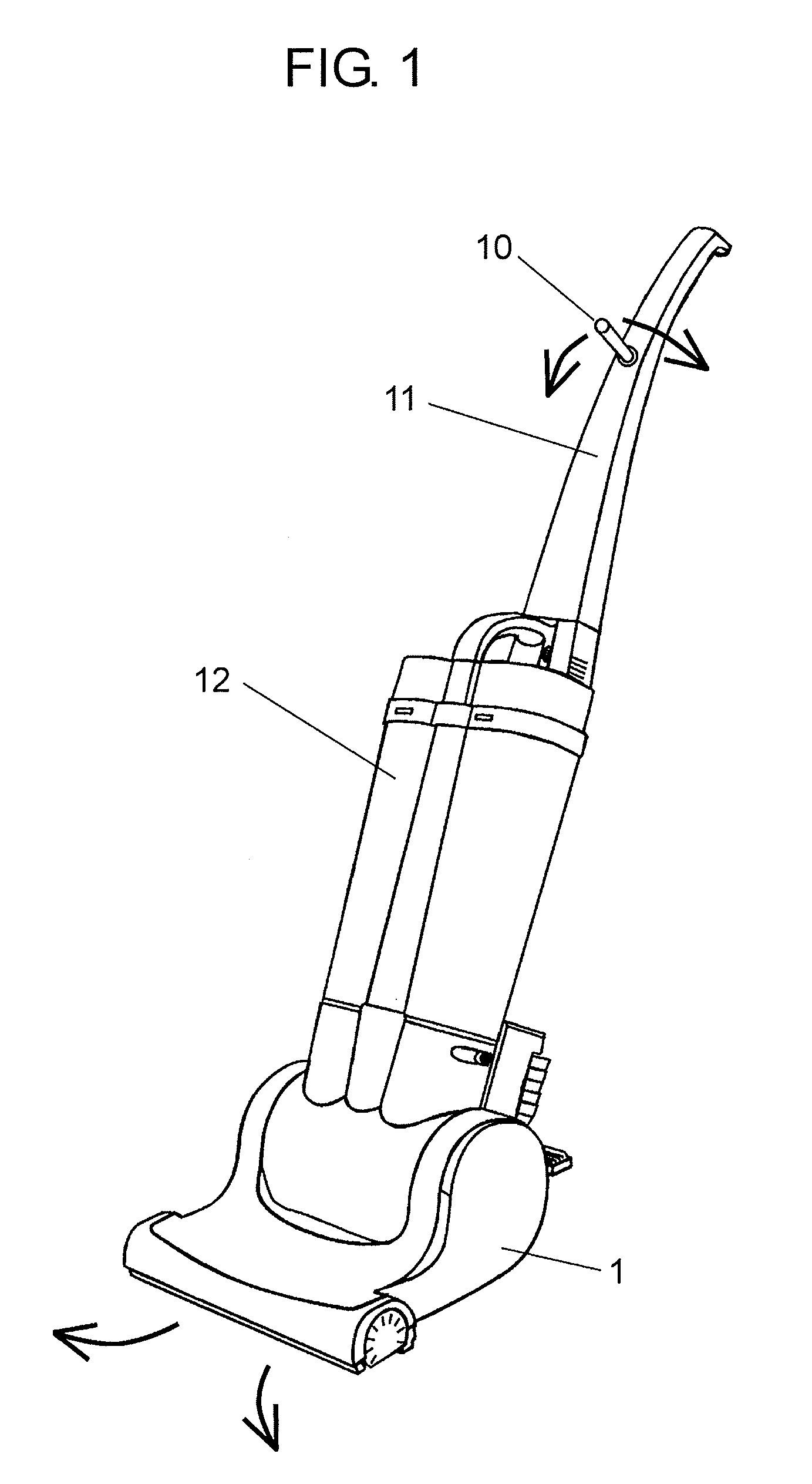

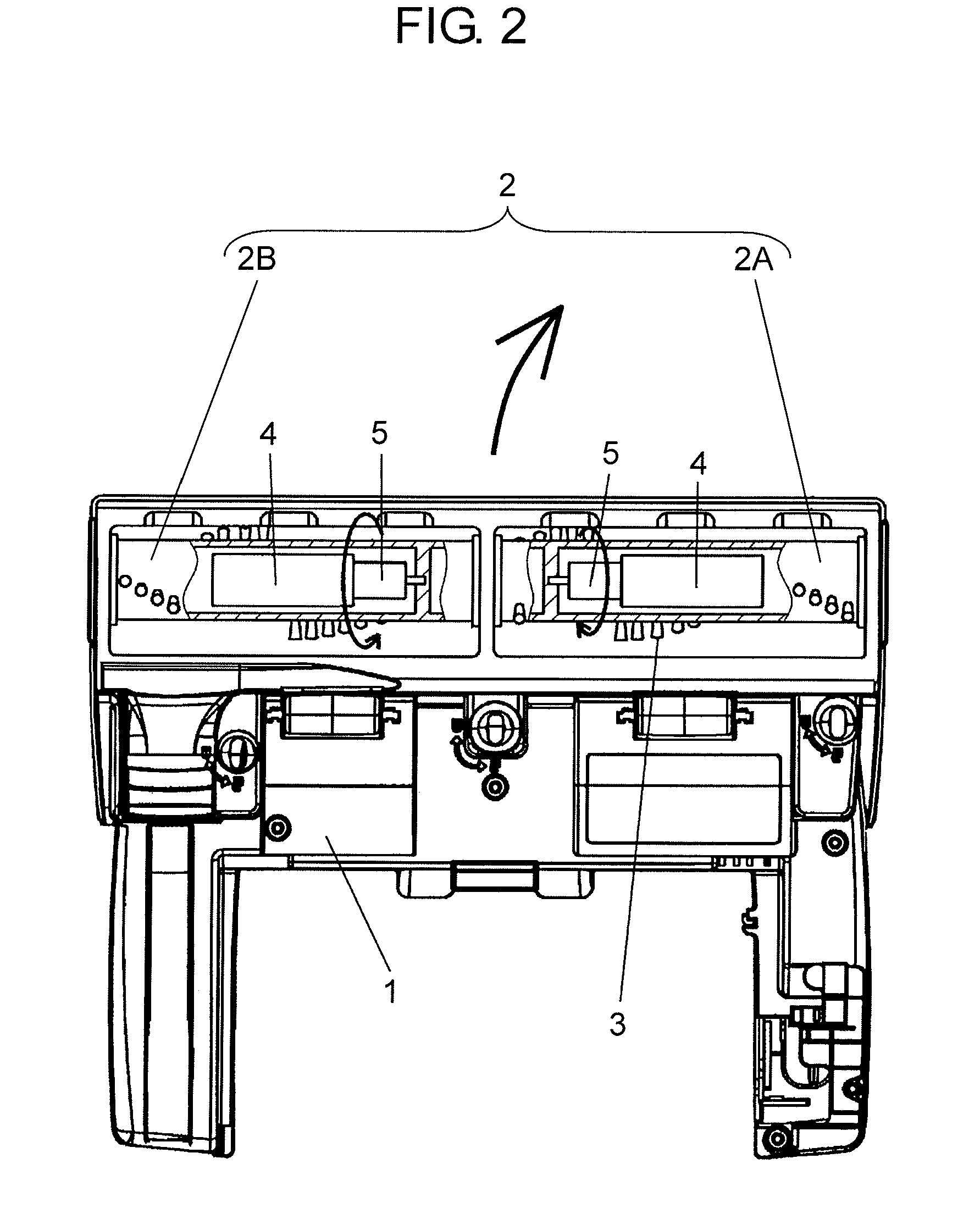

[0018]FIG. 1 is an entire perspective view showing a cleaner body portion of an electric vacuum cleaner according to a first embodiment of the invention. FIG. 2 is a partially sectional view showing a suction port portion according to the embodiment when seen from the bottom of the suction port portion.

[0019]As shown in FIG. 1, an electric vacuum cleaner according to this embodiment includes suction port portion 1 which sucks dust, handle portion 11 which moves suction port portion 1, and cleaner body portion 12 of which a lower portion is provided with suction port portion 1 and an upper portion is provided with handle portion 11. Cleaner body portion 12 includes an electric blower for generating a suction wind. Suction port portion 1 sucks dust together with the suction wind generated by the electric blower. Switch lever portion 10 is attached onto handle portion 11. Switch lever portion 10 is attached to a position where switch lever portion 10 is operable by a finger when grippi...

second embodiment

[0037]FIG. 4 is an entire perspective view showing the electric vacuum cleaner according to a second embodiment of the invention. This embodiment is different from the first embodiment in that switch lever portion 10 is not provided. Instead of switch lever portion 10, handle portion 11 which is twistable in the left and right direction is provided. The rotation speed of two rotary shaft bodies 2A and 2B disposed in rotary brush unit 2 inside suction port portion 1 is controlled through the electric controller (not shown) so that the direction of suction port portion 1 is changed to the twisting direction of handle portion 11. When the twisting amount becomes large, the difference in the rotation speed between rotary shaft bodies 2A and 2B becomes large, and the turning amount becomes large. In the case where handle portion 11 is not twisted, suction port portion rotates forward. Since the other configurations are same as those of the first embodiment, detailed description thereof w...

third embodiment

[0039]FIG. 5 is a plan view showing rotary brush unit 2 inside suction port portion 1 of the electric vacuum cleaner according to a third embodiment of the invention. Rotary shaft bodies 2A and 2B constituting rotary brush unit 2 are rotatably connected to each other through connection portion 30. Connection portion 30 is formed as a simple bearing, and a difference in the rotation speed between rotary shaft bodies 2A and 2B is absorbed by connection portion 30. Brush 3 is attached to surfaces of rotary shaft bodies 2A and 2B.

[0040]Stiff brushes 3A depicted by the solid line are attached to predetermined ranges 101 of rotary brush unit 2. Soft brush 3B depicted by the dotted line is attached to predetermined ranges 102 at the center of rotary brush unit 2. Since the other configurations are the same as those of the first embodiment, detailed description thereof will be omitted.

[0041]With such a configuration, since a large self-propelling force is generated at a position far from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com