Bulk fueled gasifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

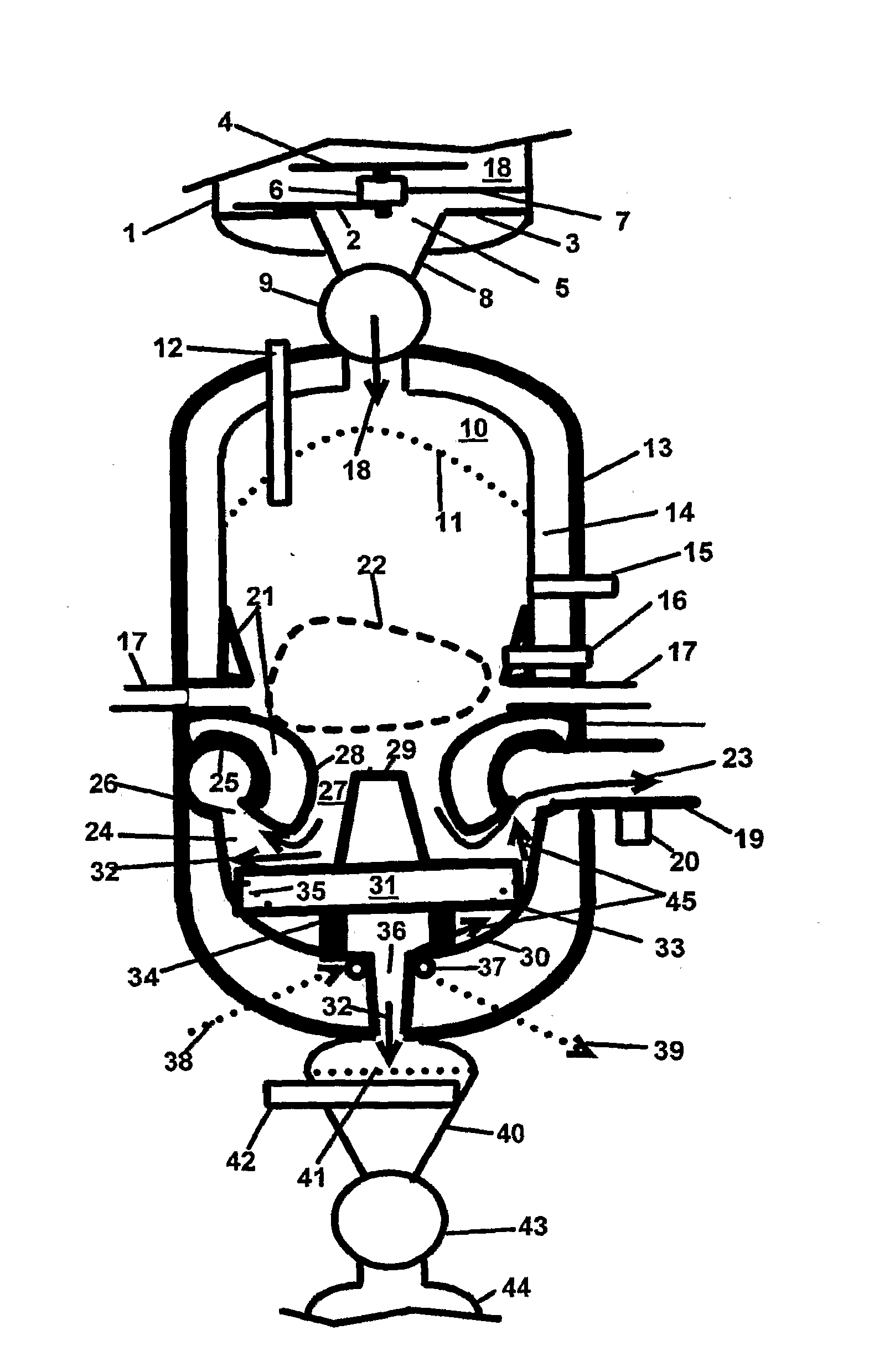

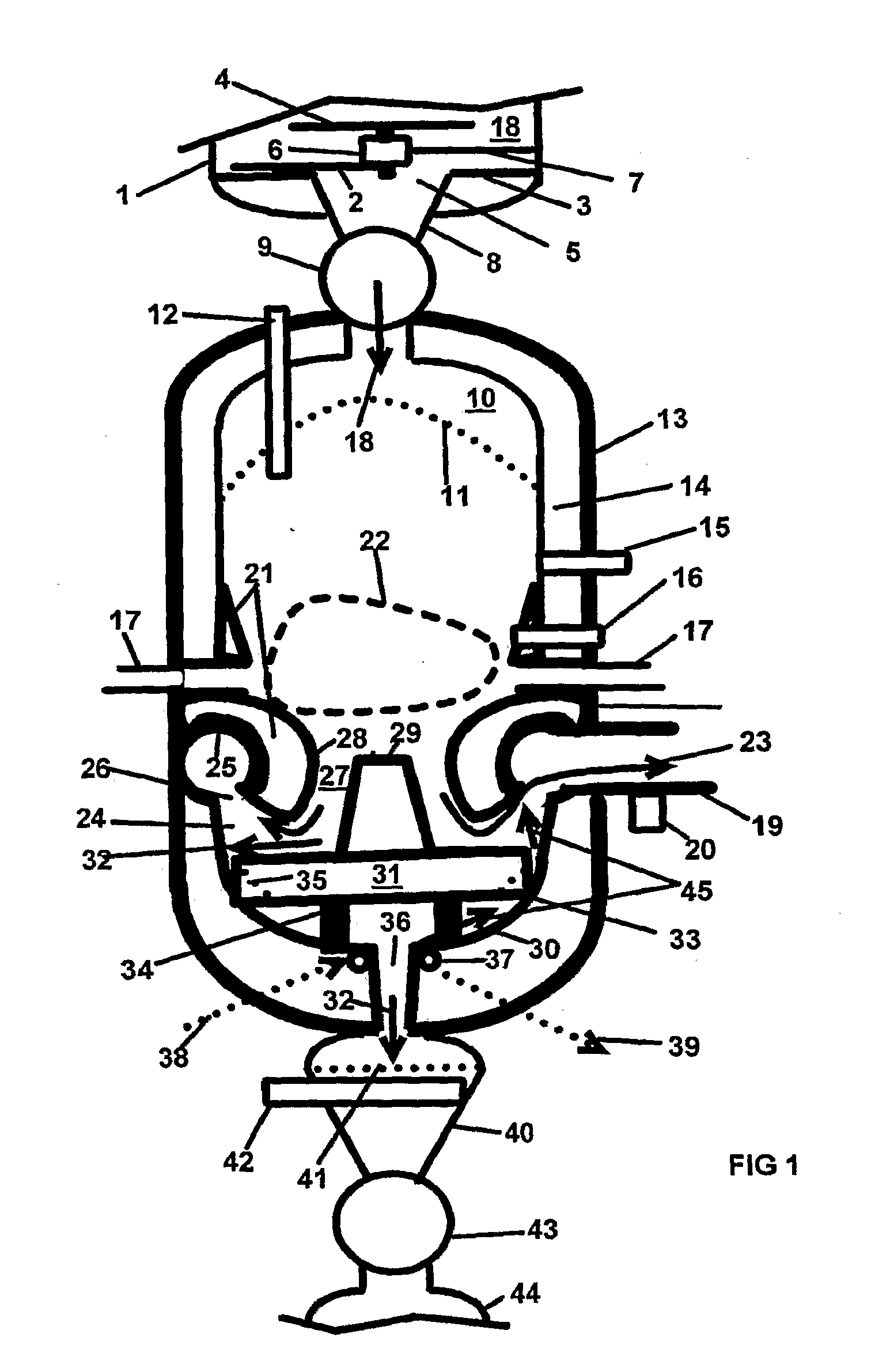

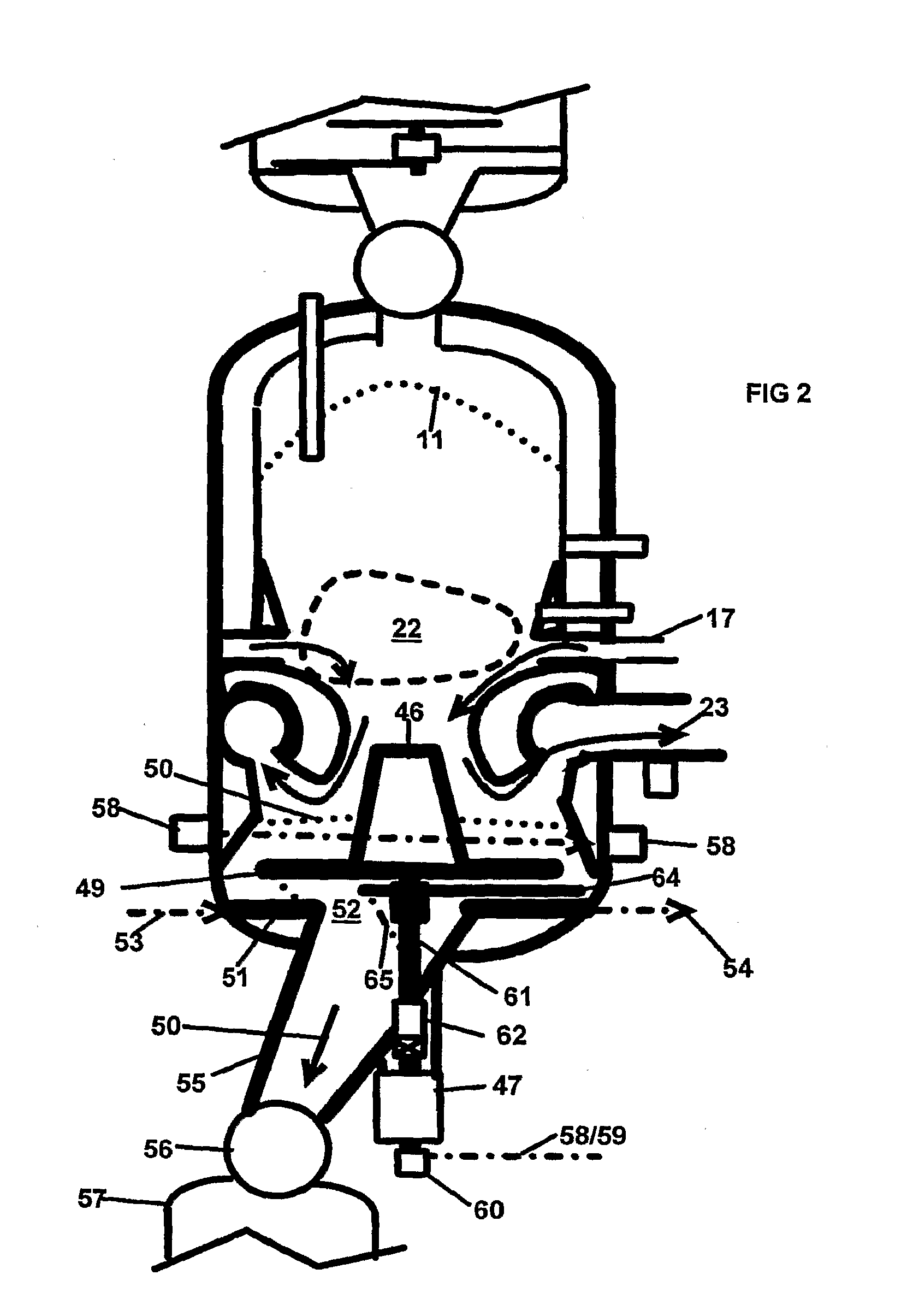

[0015]FIG. 1 shows one embodiment of a slagging gasifier as if it is being used in a pressurized operation, say up to thirty bar pressures. Valve details and controls for de-pressurizing and re-pressurizing lock hoppers and controls are well known and are not shown. The upper and body sections are described first and are the same for each ash discharge method.

[0016]Lock hopper 1 is filled using a conveyor (not shown) that has a much faster capacity than the maximum usage of the gasifier. Undercutting rotating inward helical front edge of self-aligning plate 2 performs the unloading function by pulling material from the outer perimeter of base 3 and under rotating cap 4. The loose spline drive connection of unloader plate 2 to drive motor 6 allows plate 2 to conform perfectly to base 3 when rotating, reducing friction and eliminating binding forces. Cap 4 prevents free fall of fuel or material 18 into unloader concentric opening 5. In conjunction with inward rotating helix plate 2, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com