High Velocity Low Impact Liquid Feed Distributor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

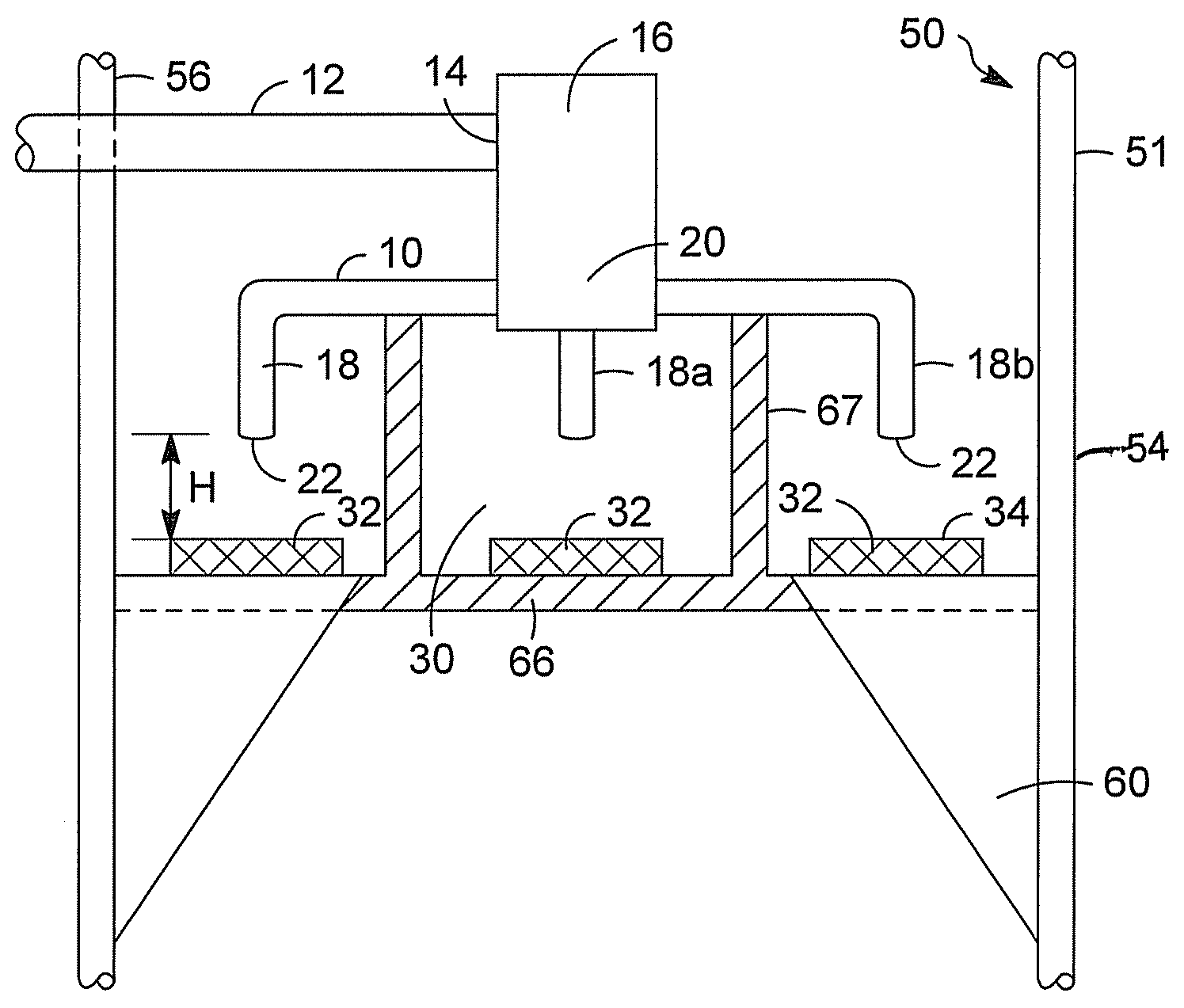

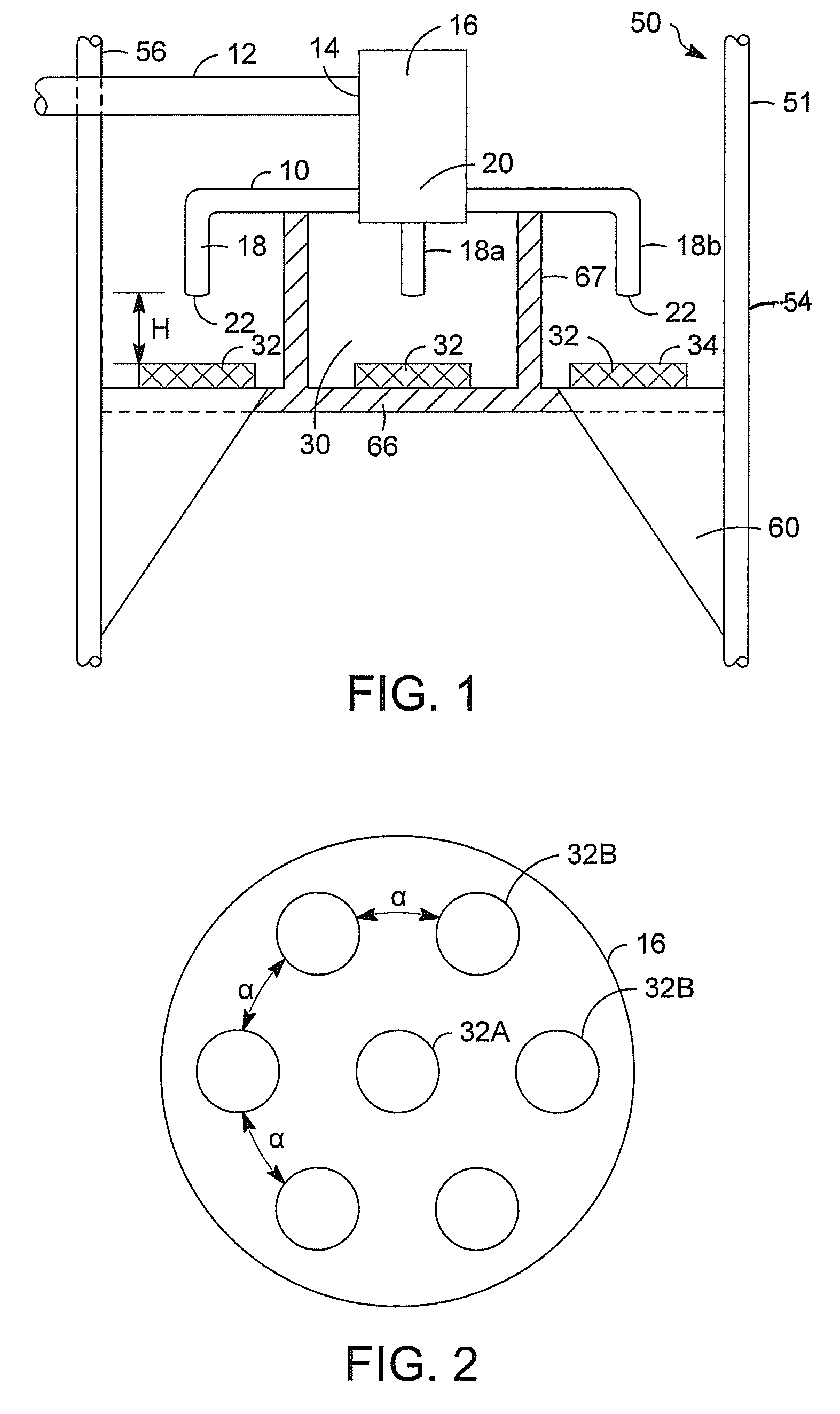

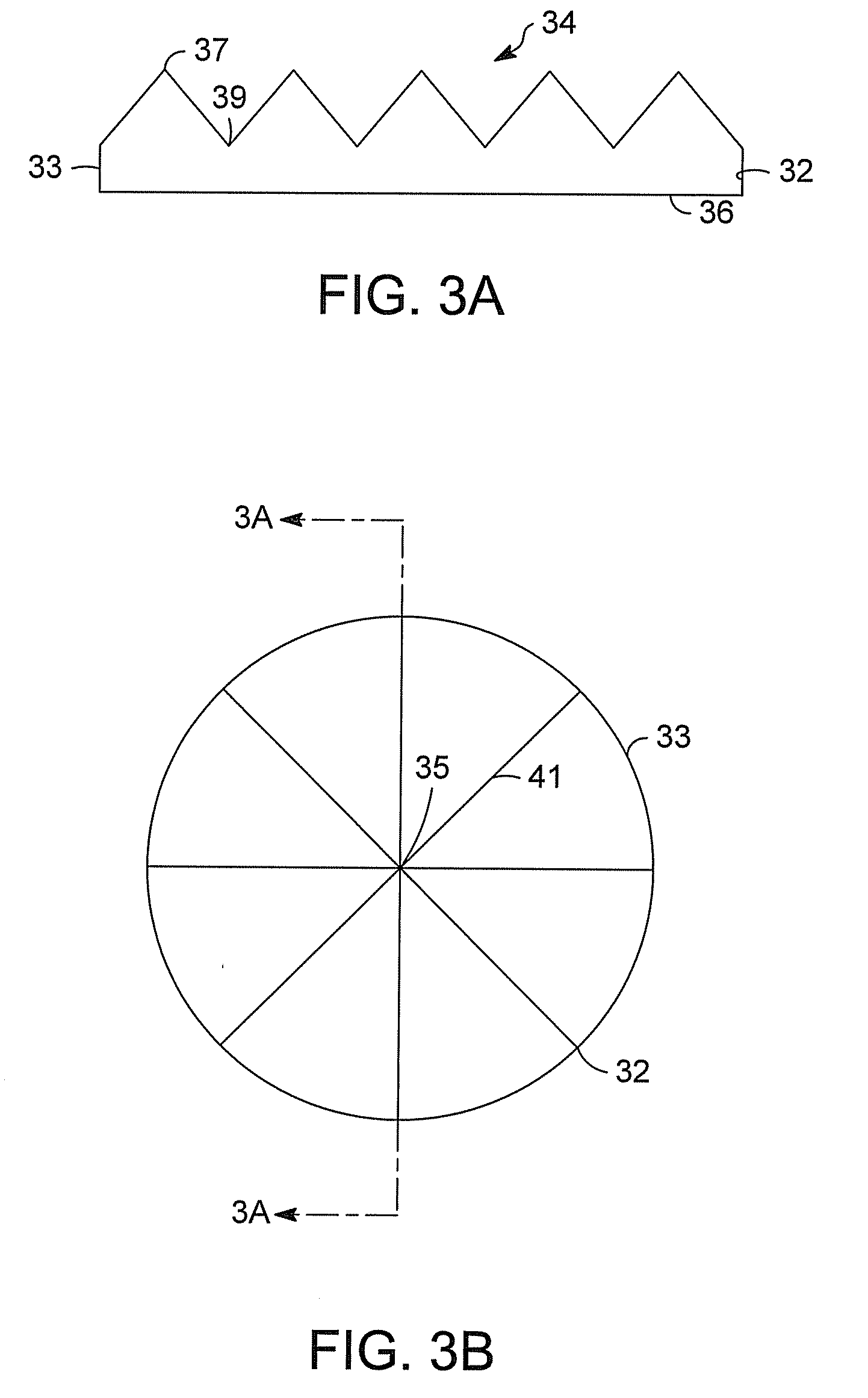

[0014]The present invention is directed to liquid distribution devices that are useful for quickly directing liquids moving at high initial velocities into liquid containing vessels and thereafter quickly reducing the velocity of the introduced liquid to uniformly distribute the introduced liquid in the vessel. Unlike liquid distributors of the prior art, the liquid distribution devices of this invention do not include small orifices. Therefore, the present invention solves at least some of the problems associated with distributing liquids at low velocity through a multitude of small orifices. The liquid distribution devices of this invention solve some of the prior art distribution problems because they include a plurality of liquid distribution pipes that direct liquids at high velocities towards opposing pans. When the high velocity liquid exiting the distribution pipe outlets impacts the pans, the liquid flow is redirected and further distributed causing a substantial reduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com