Bow retainer clips for shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

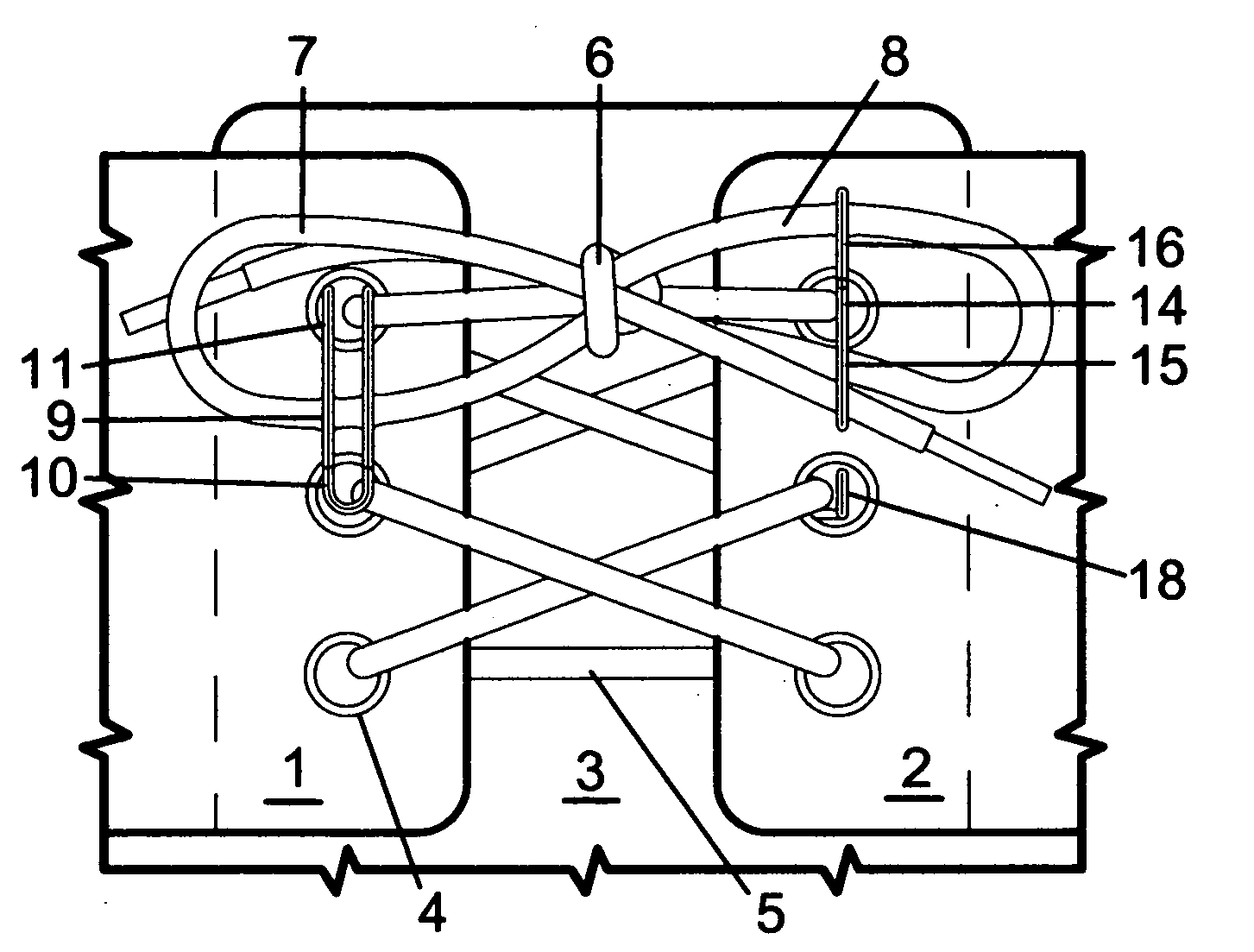

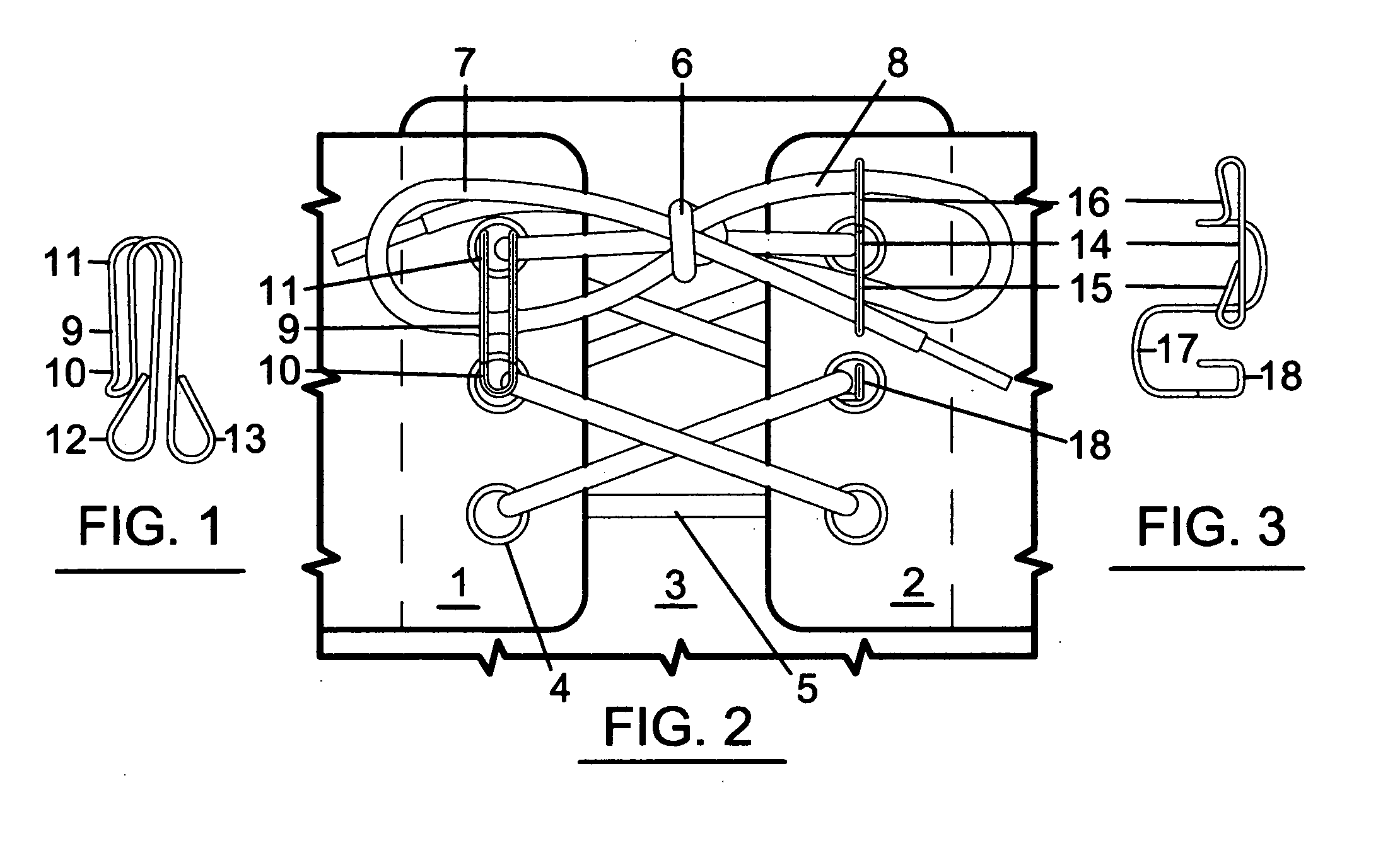

[0014]A typical lace-up shoe as shown in FIG. 2 has a tongue, 3, that fits below the grommet areas of the shoe, 1 and 2. Shoe lace, 5, is threaded through the various grommets, 4, to allow bows, 7 and 8, to be formed by bow knot, 6. Type One bow retainer clips, as shown in FIG. 1, can be installed by removing the laces from the two rows of grommets at the top of the shoes. The upturned, horseshoe bend, 10, is then threaded from the tongue area, 3, outward, though the top grommet, which is below 11, in FIG. 2. Such insertion is facilitated by the overall springiness of the formed wire part which is shown in FIG. 1. Once the parallel wire portions, 10, 9, 11, are inserted through the top grommet, the looped ends, 12 and 13, can be positioned below the second grommet so as to allow lace, 5, to be threaded through the second grommet above 4, and then through one or both loops, 12 and 13. Due to the flexibility of the clip shown in FIG. 1, the teardrop shaped loops, 12 and 13, may be squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com