Fluid conditioning system

a technology of conditioning system and water, which is applied in the field of medical cutting, irrigating, evacuating, cleaning and drilling techniques, can solve the problems of inability to use aesthetically pleasing substances, not being able to meet the needs of patients, etc., and may not be commonly applied during such laser cutting operations. , the effect of reducing the risk of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

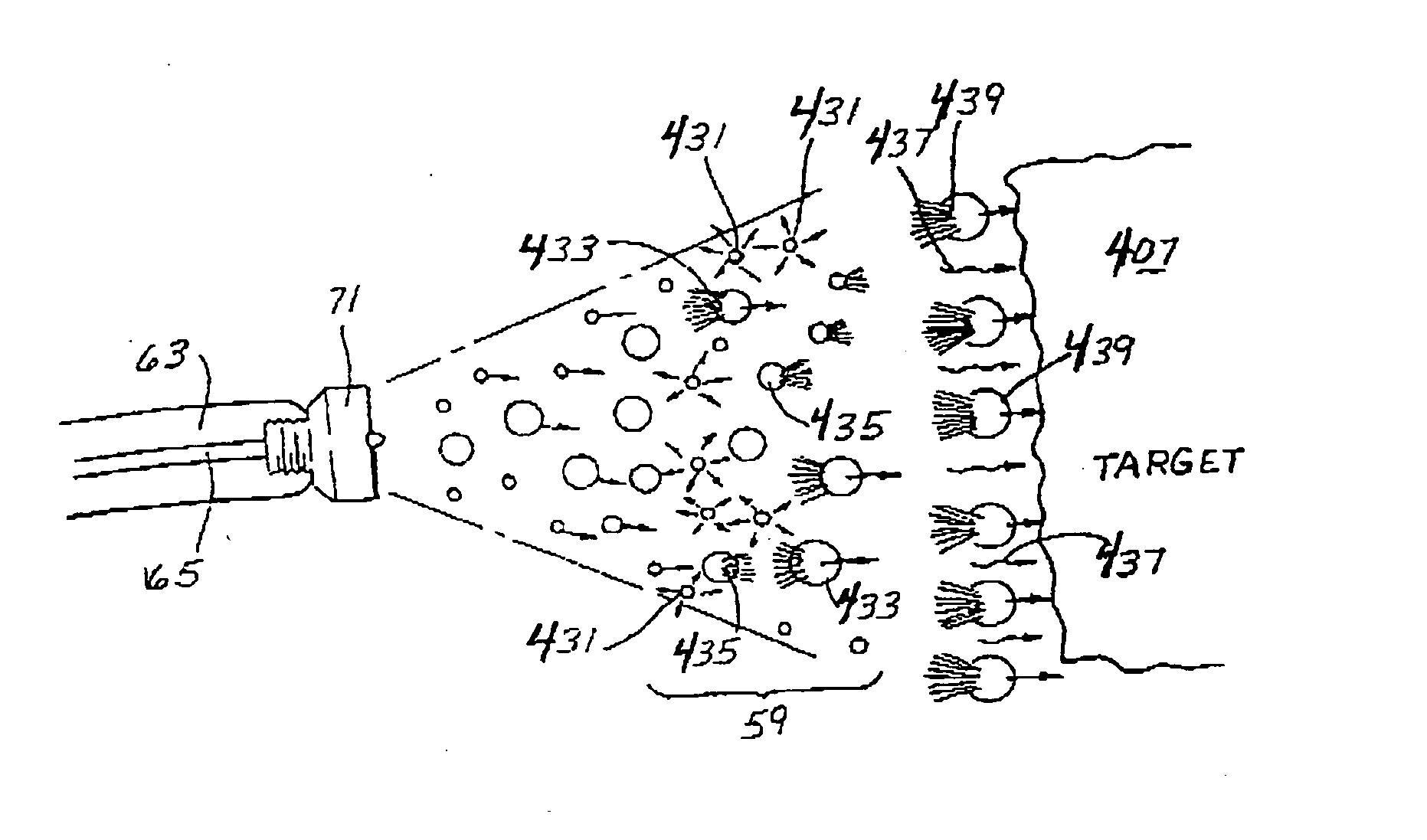

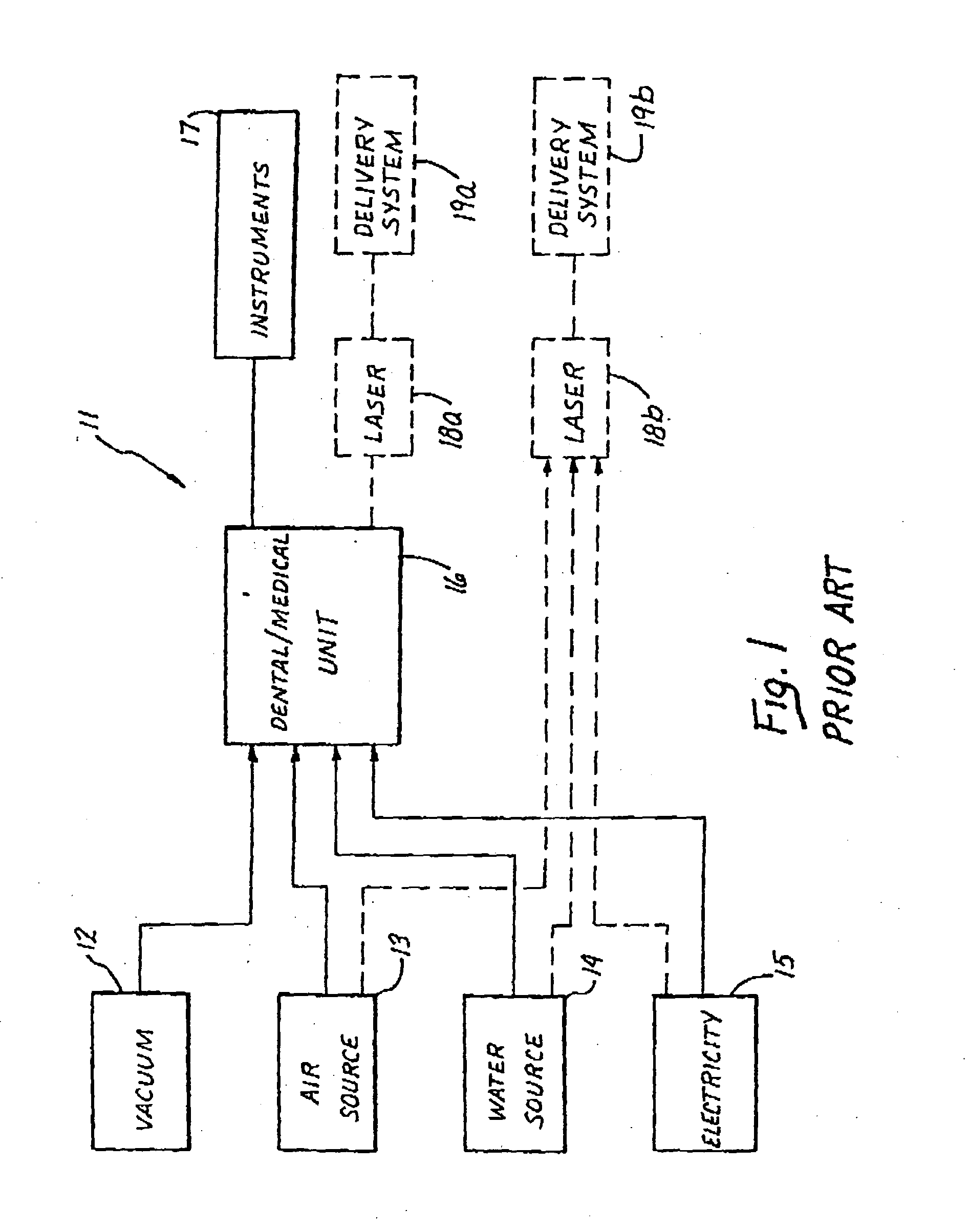

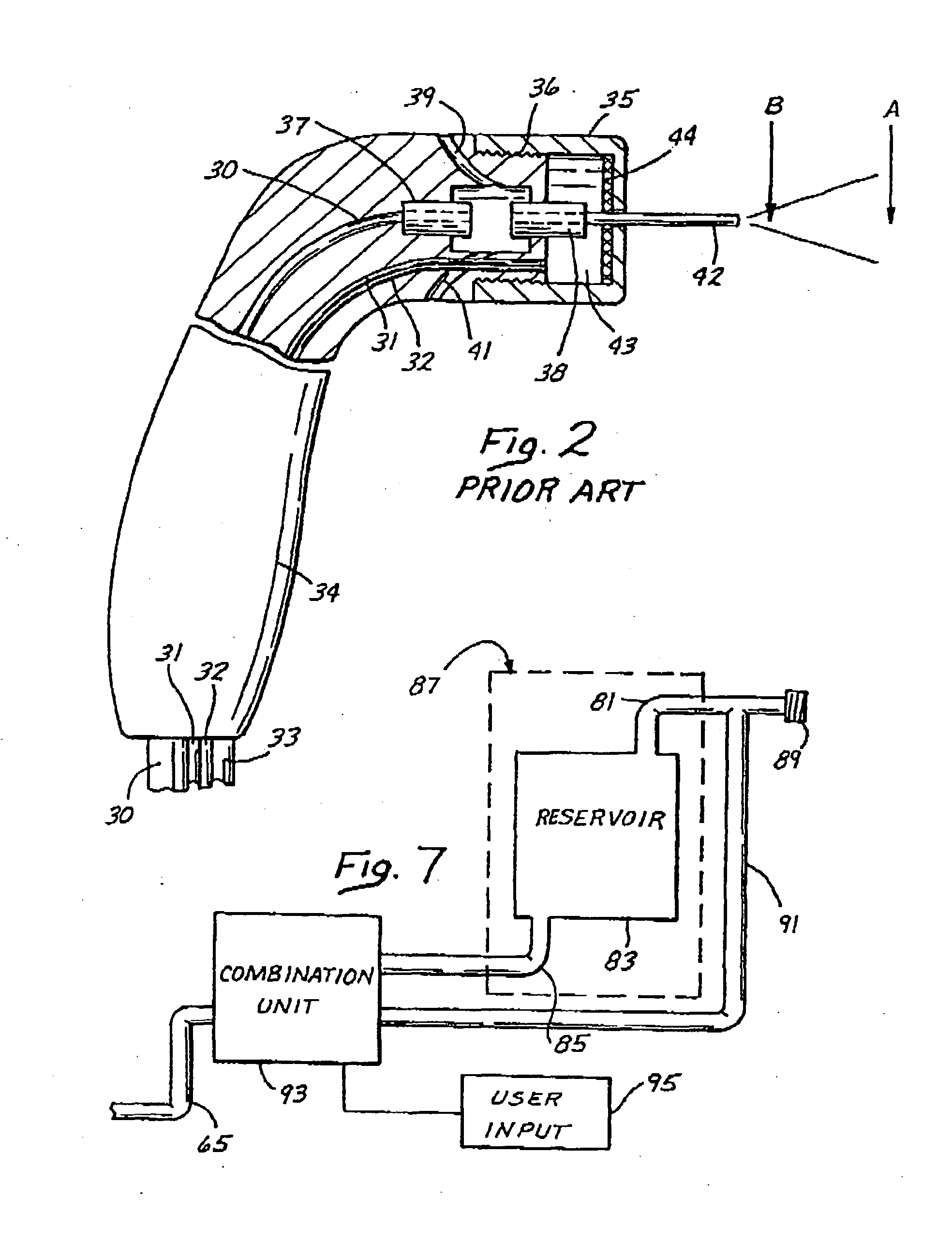

[0050]Embodiments of the invention are now described and illustrated in the accompanying drawings, instances of which are to be interpreted to be to scale in some implementations while in other implementations, for each instance, not. In certain aspects, use of like or the same reference designators in the drawings and description refers to the same, similar or analogous components and / or elements, while according to other implementations the same use should not. According to certain implementations, use of directional terms, such as, top, bottom, left, right, up, down, over, above, below, beneath, rear, and front, are to be construed literally, while in other implementations the same use should not. The present invention may be practiced in conjunction with various devices and techniques that are conventionally used in the art, and only so much of the commonly practiced process steps are included herein as are necessary to provide an understanding of the present invention. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com