Guardrail Post Base

a post base and guardrail technology, applied in the direction of fencing, ways, buildings, etc., can solve the problems of requiring a relatively large amount of time, affecting the safety of workers and equipment, and reducing the service life of workers, so as to achieve convenient installation and save time and money.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

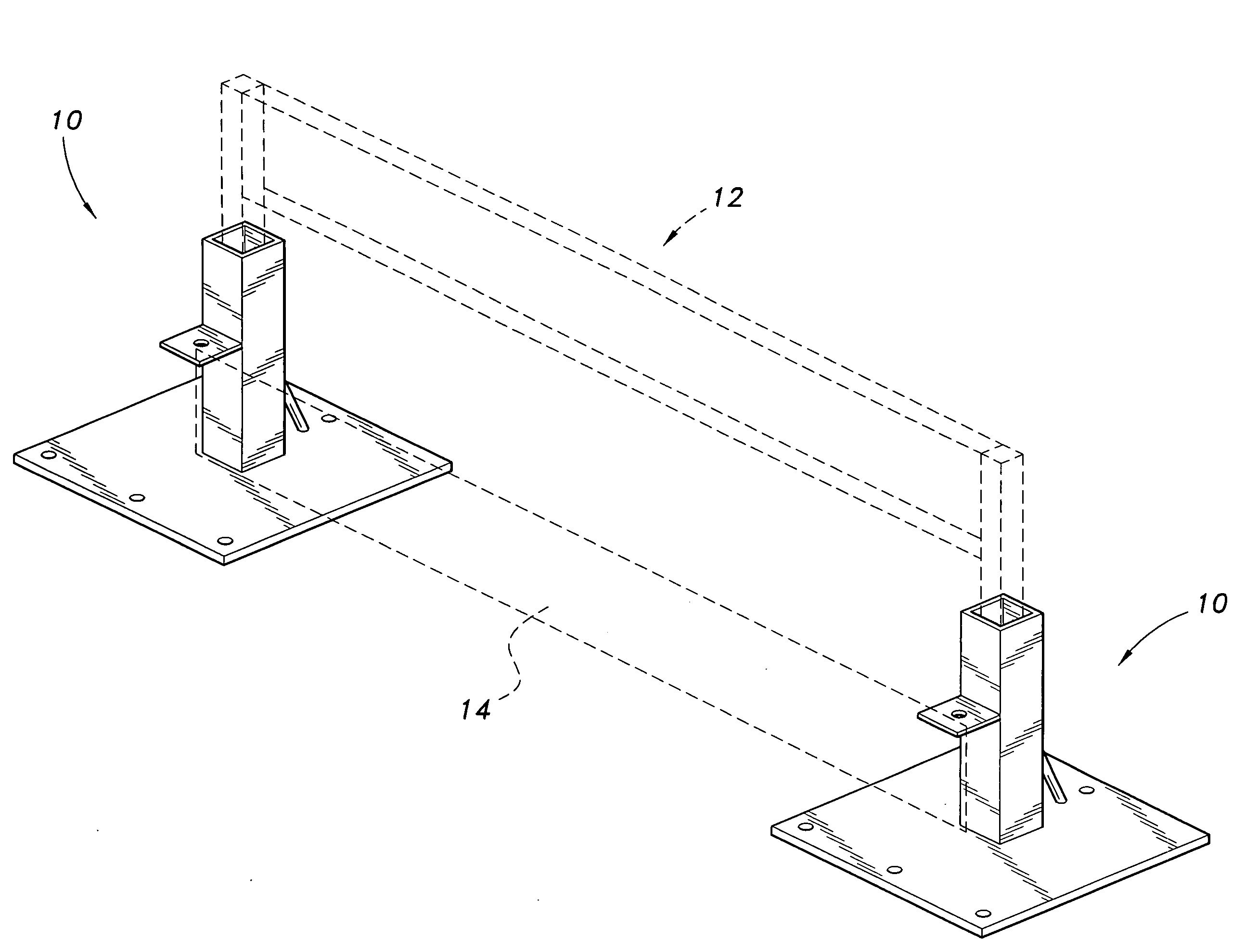

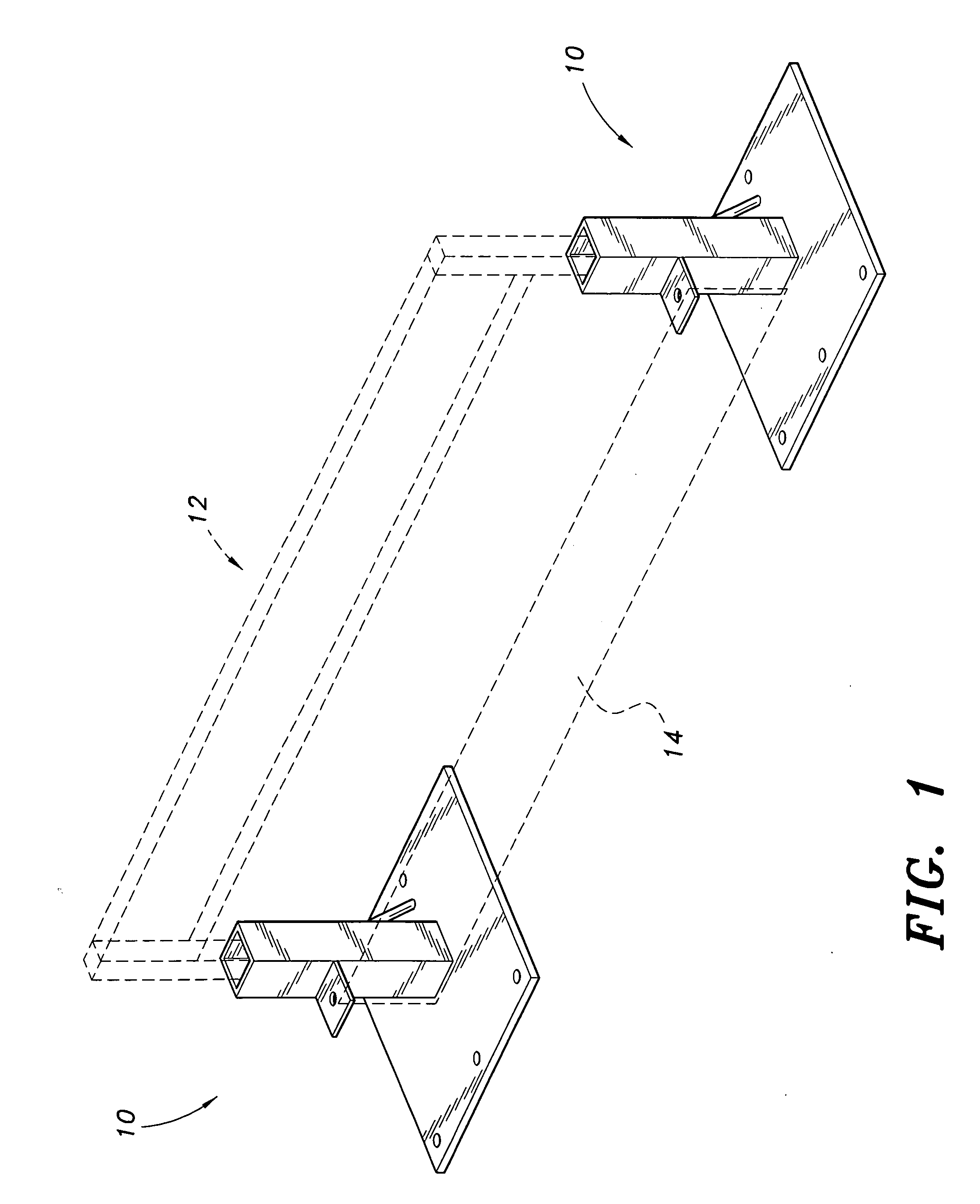

[0012]Attention is first directed to FIG. 1, wherein the guardrail post base is generally indicated at 10. A pair of post bases 10 support a post and safety rail section 12 and kick board 14 (both shown in phantom lines) thereon. Post and safety rail section 12 and kick board 14 are conventional and are not per se part of the inventive concept. As discussed above, post bases 10 are attached on the perimeter of the floor (not shown) of a building under construction. Post and safety rail section 12 is mounted in the post base to provide fall protection for personnel. Kick board 14 prevents tools from being accidentally pushed from the edge of the floor.

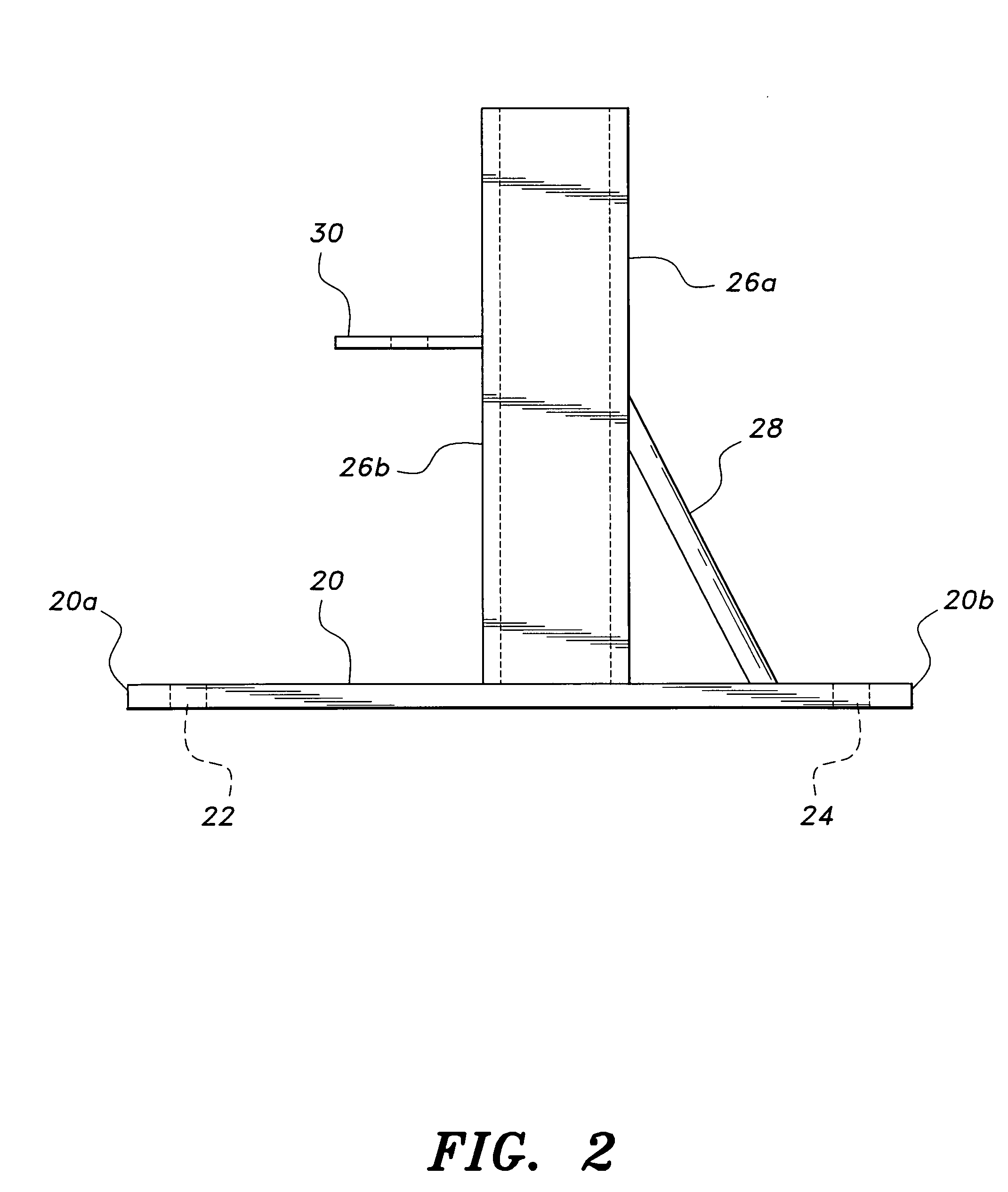

[0013]As best seen in FIGS. 2 and 3, post base 10 comprises a ¼″×8″×8″ base plate 20. A plurality of fastener holes 22 are spaced along one edge 20a of base plate 20. A single fastener hole 24 is centered on opposite edge 20b. A square, hollow tube 26 1½″×1½″ having ¼″ thick walls is centered on the upper surface of base plate 20 and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com