Vapor chamber with wick structure of different thickness and die for forming the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The detailed description and technical contents of the present invention will be explained with reference to the accompanying drawings. However, the drawings are illustrative only but not used to limit the present invention.

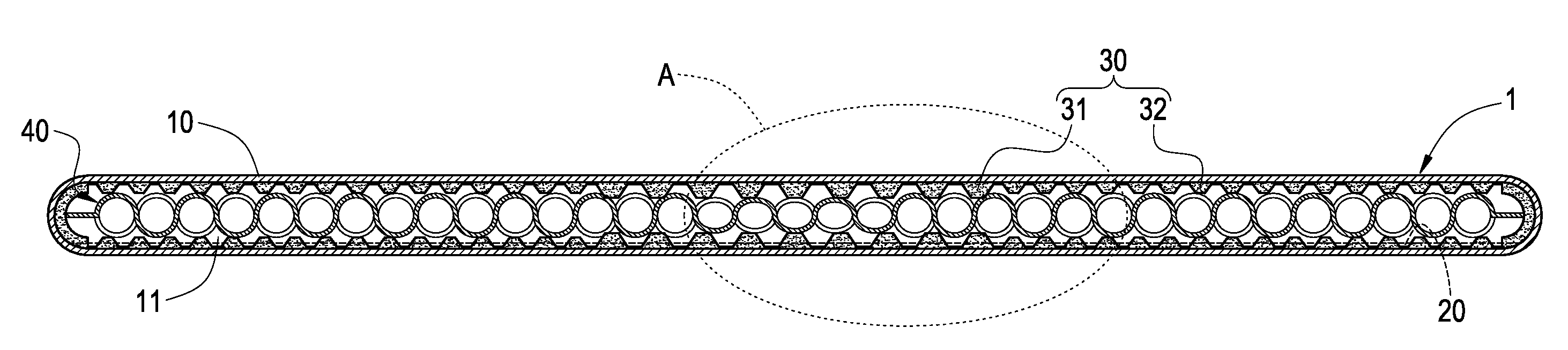

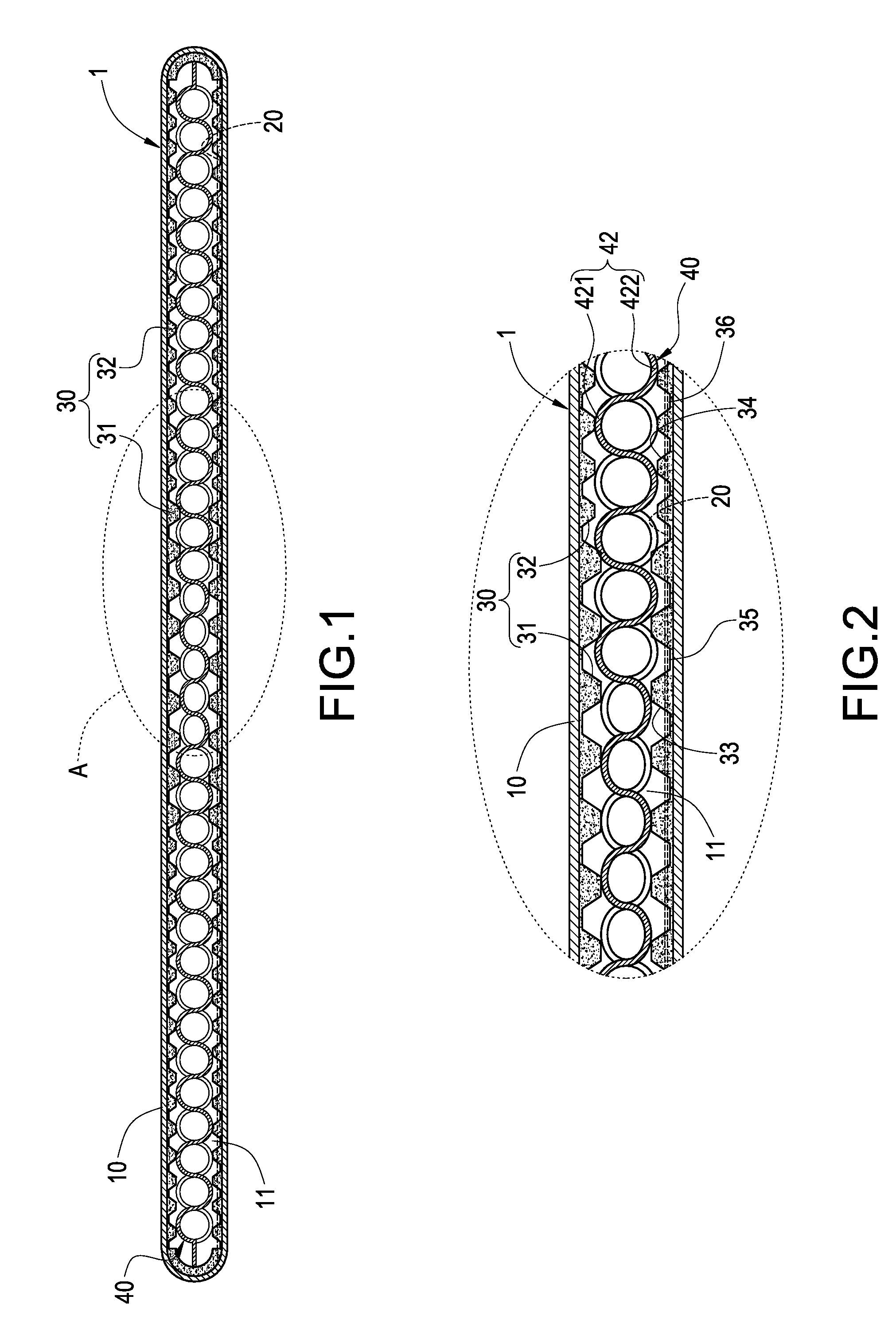

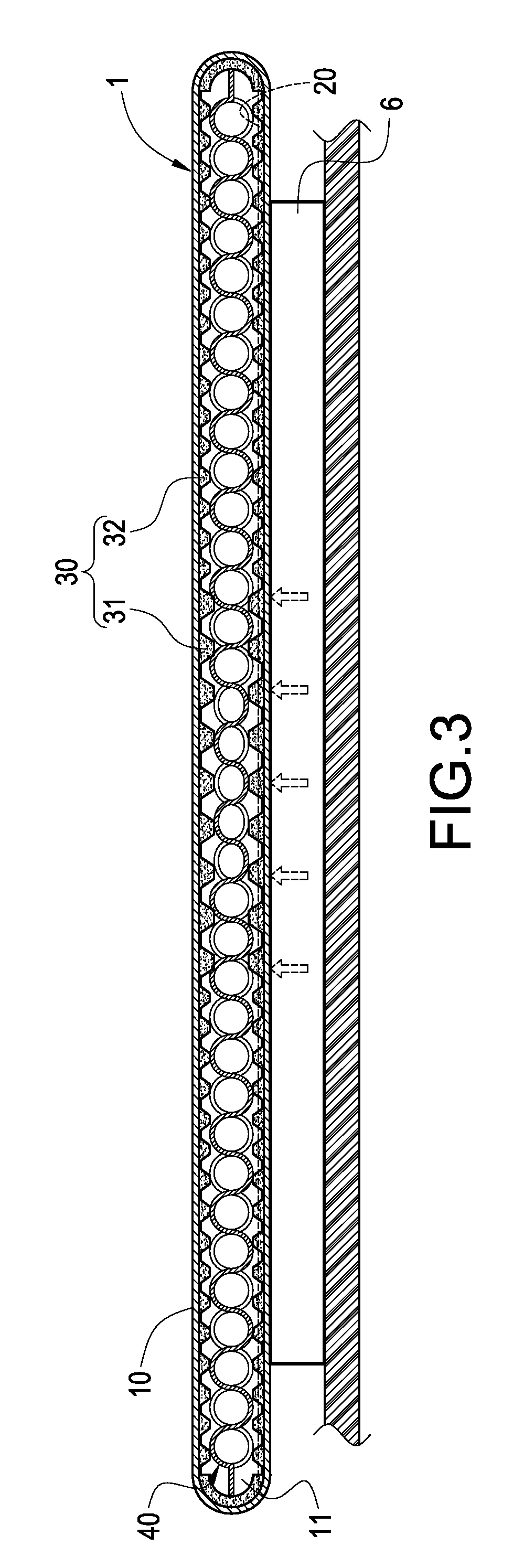

[0025]Please refer to FIGS. 1 and 2. The present invention provides a vapor chamber 1 with a wick structure of different thickness, which is constituted of a casing 10, a working fluid 20, a wick structure 30 and a supporting body 40.

[0026]The casing 10 is made of copper or aluminum. The interior of the casing 10 is formed with a chamber 11.

[0027]The working fluid 20 is filled in the chamber 11. The working fluid 20 can be pure water, alcohol, methanol, ethanol or propyl alcohol, but it is not limited thereto.

[0028]The wick structure 30 is adhered to the inner wall of the chamber 11. The wick structure 30 has a first wick section 31 and a second wick section 32 extending from the first wick section 31. The thickness of the wick section 31 is larger than tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com