Rotation shaft supporting structure with journal bearing and assembling method of the bearing

a technology of supporting structure and bearing, which is applied in the direction of shaft and bearing, rotary bearing, bearing, etc., can solve the problems of mechanical efficiency decline, bearing seizure, overheating of the bearing surface of the tilting pad, etc., to prevent the occurrence of burning out of the bearing surface, favorable lubrication property, and lubrication of the bearing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067]A preferred embodiment of the present invention will now be detailed with reference to the accompanying drawings. It is intended, however, that unless particularly specified, dimensions, materials, relative positions and so forth of the constituent parts in the embodiments shall be interpreted as illustrative only not as limitative of the scope of the present invention.

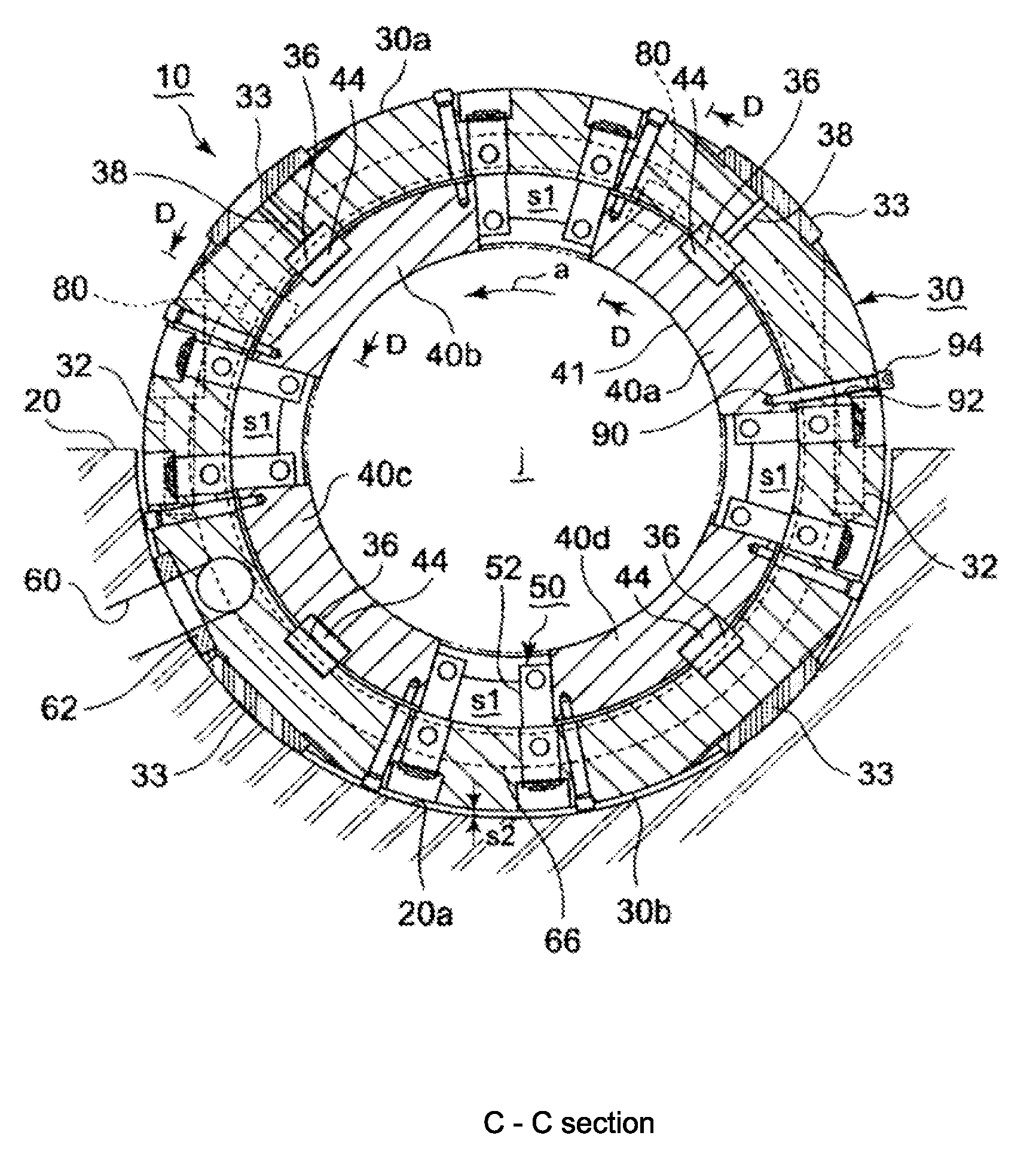

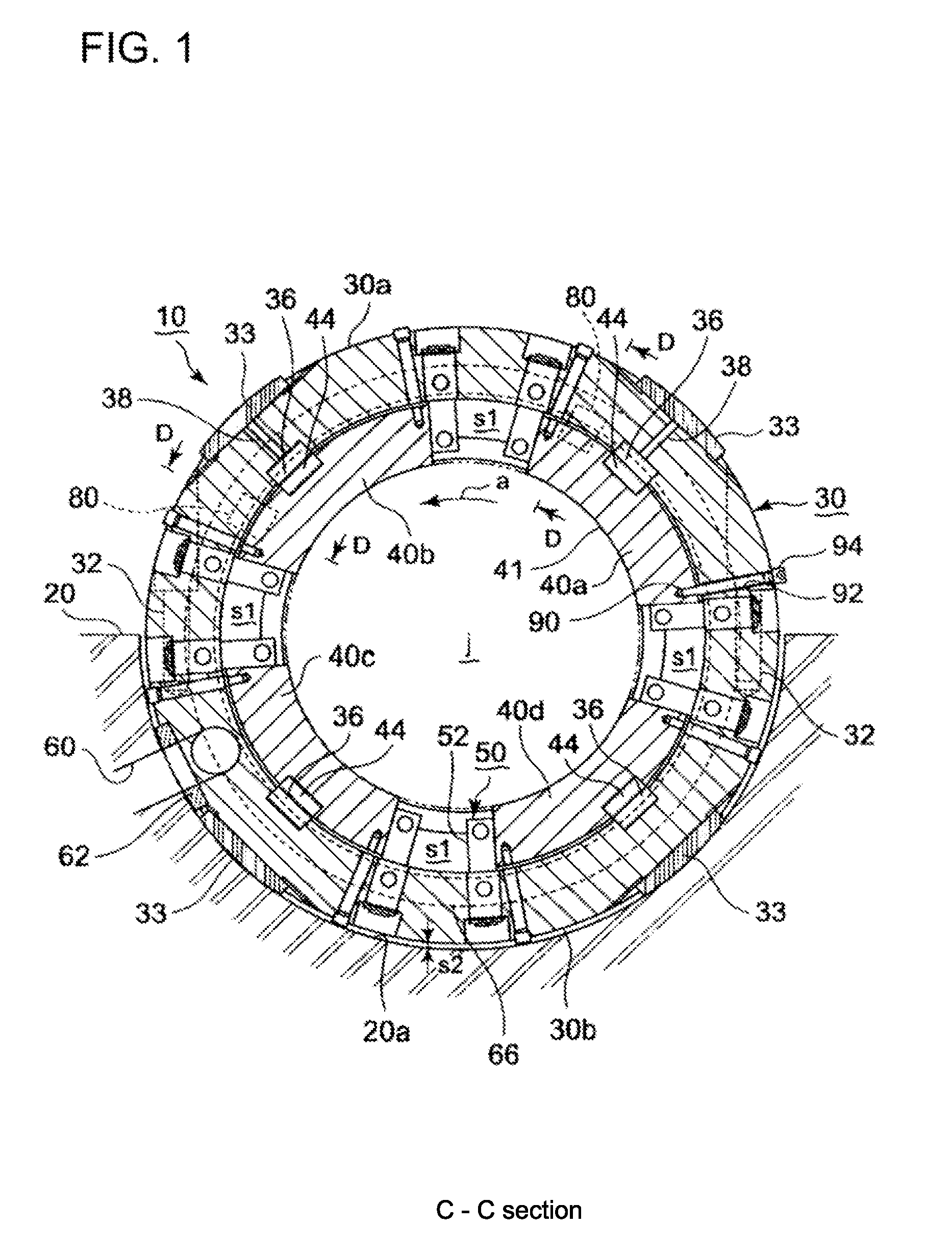

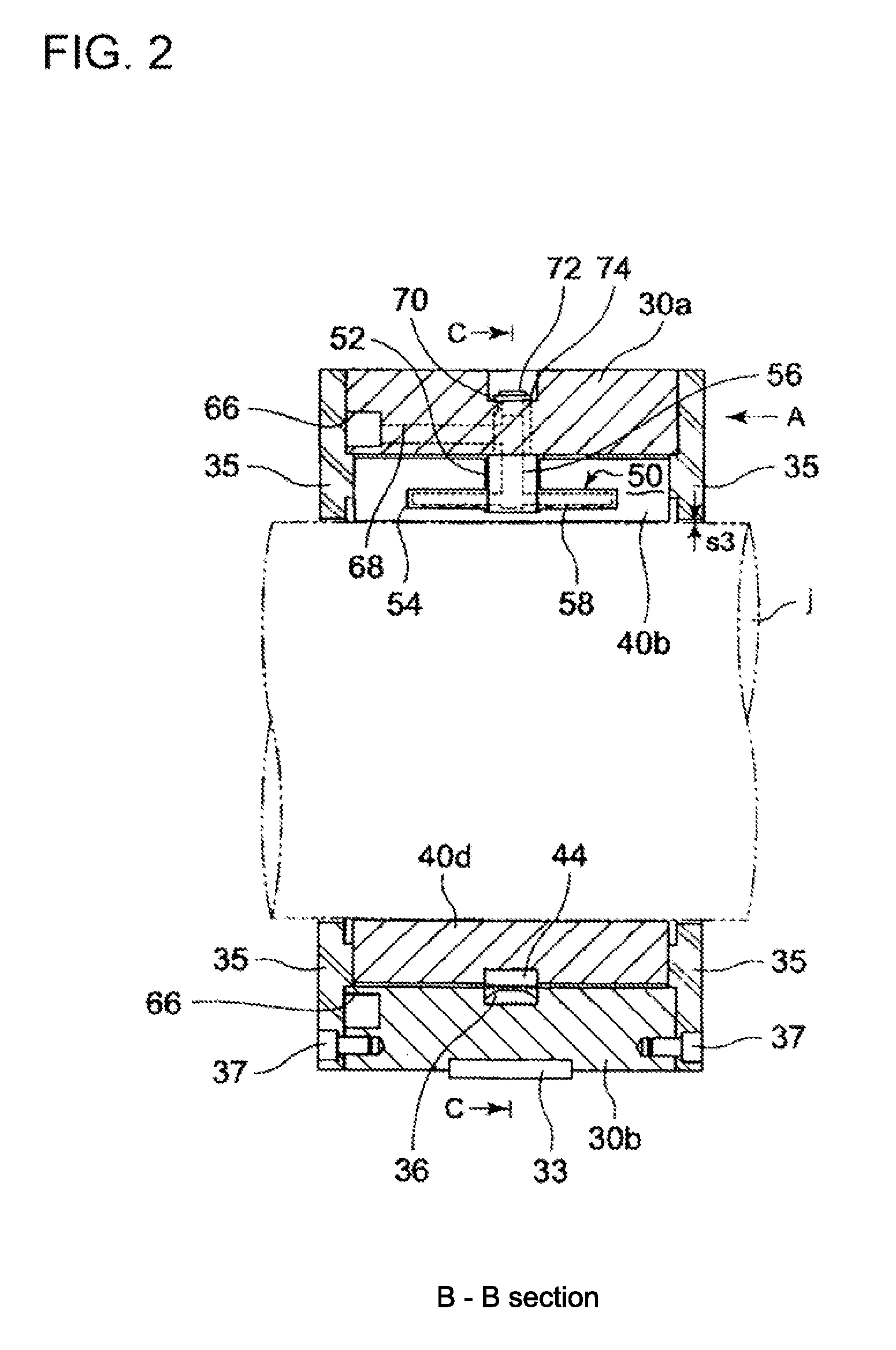

[0068]FIGS. 1 to 3 show an embodiment of the journal bearing of the invention, FIG. 1 is a sectional front view along line C-C in FIG. 2, FIG. 2 is a sectional side view along line B-B in FIG. 3, and FIG. 3 is a rear view viewed in the direction of arrow A in FIG. 2.

[0069]In FIG. 1, a journal j is a rotation shaft of large rotating machine such as a steam turbine, gas turbine, and an electric generator. The diameter of the journal j is as large as about 40 cm, so a journal bearing 10 to support the journal j becomes large in size, and circumferential velocity of the journal j becomes high. The journal j rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com