Electric scissors

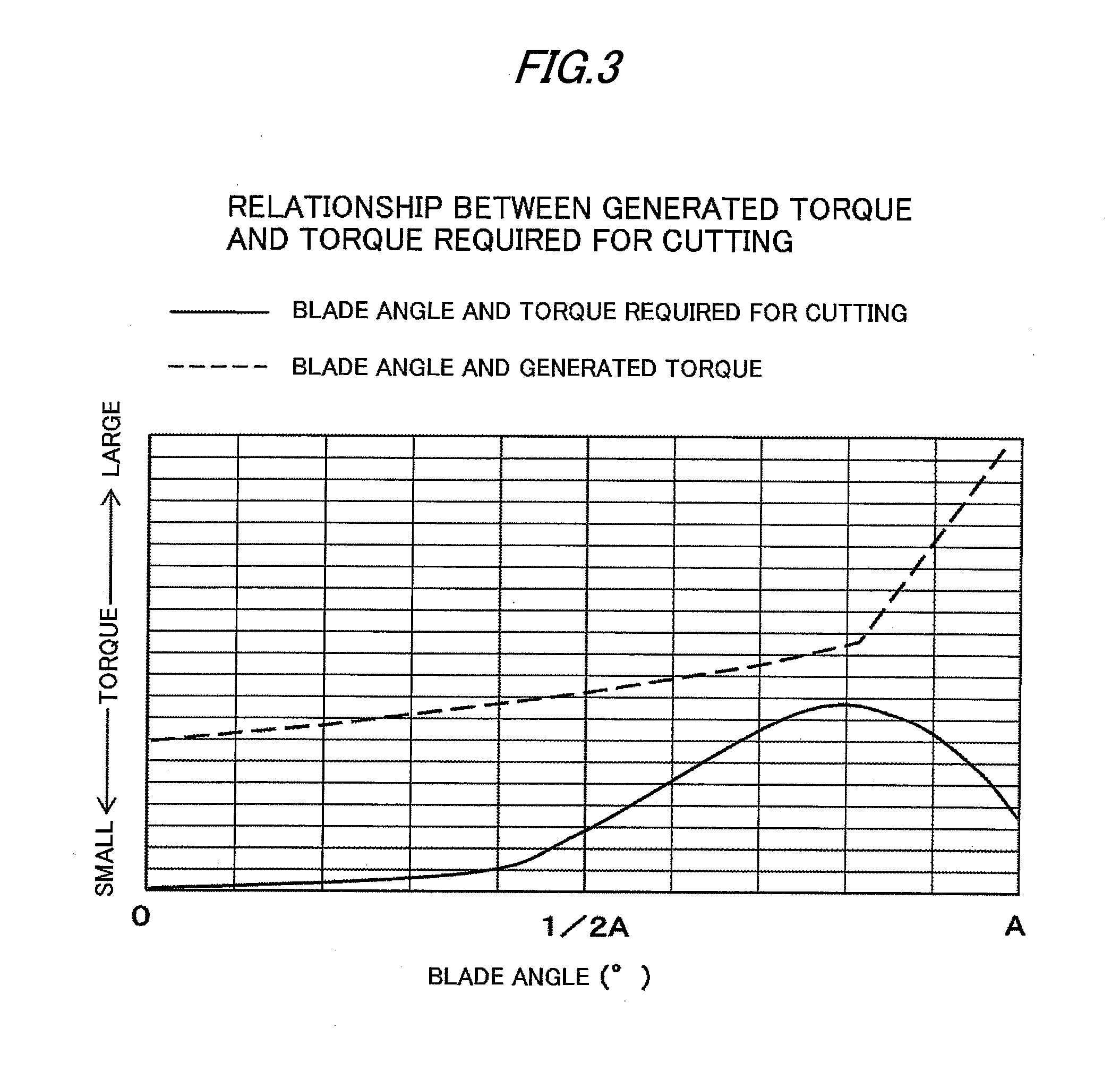

a technology of electric scissors and blades, applied in the field of electric scissors, can solve the problems of large torque required as the blades are closed, deformation of the durability of the drive system, and application to the drive system, and achieve the effects of large cutting torque, large cutting torque, and increased cutting for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

A Configuration Example of Electric Scissors

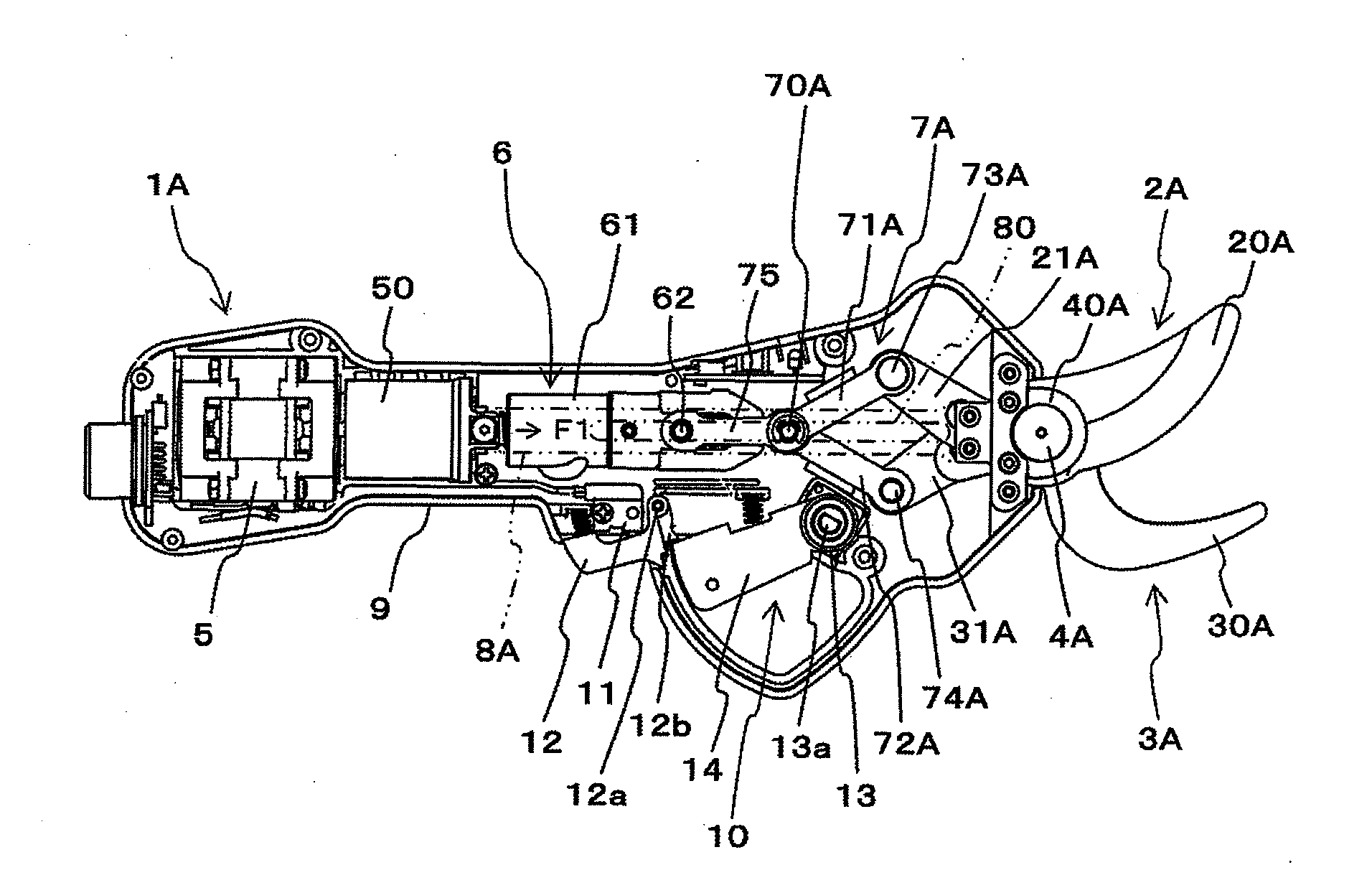

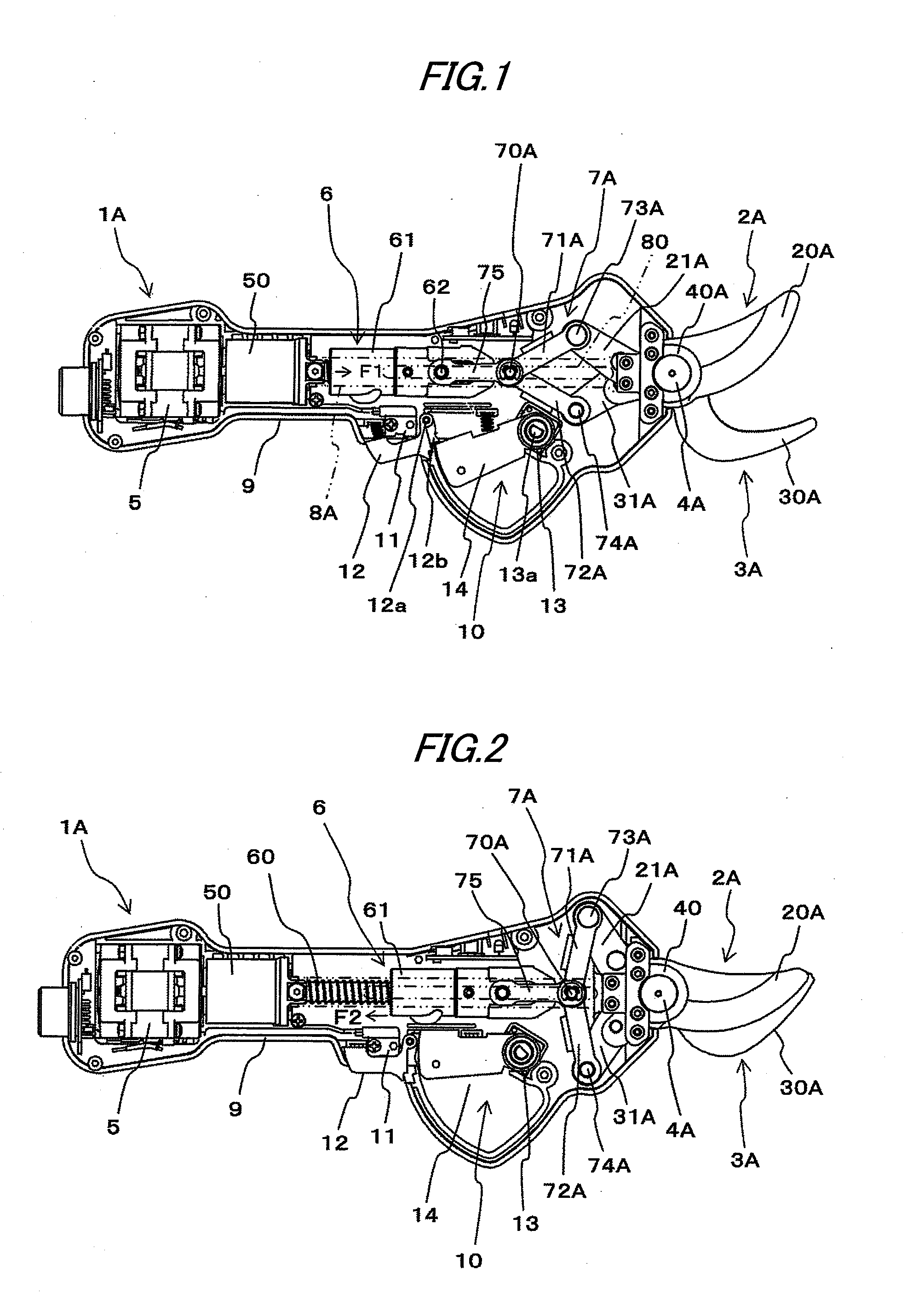

[0029]FIGS. 1 and 2 are side sectional views showing a configuration example of electric scissors according to a first exemplary embodiment. FIG. 1 shows a state in which the blades thereof are opened, and FIG. 2 shows a state in which the blades are closed.

[0030]In electric scissors 1A according to the first exemplary embodiment, a first movable blade 2A and a second movable blade 3A are rotatably supported by a shaft 4A serving as a fulcrum.

[0031]In the electric scissors 1A, the rotation of a motor 5 is converted into a linear motion using a ball screw mechanism 6, and the drive power of the motor 5, the rotation of which is converted into a linear motion, is transmitted to the first movable blade 2A and the second movable blade 3A using a toggle link mechanism 7A. As a result, the first movable blade 2A and the second movable blade 3A are rotated around the shaft 4A serving as a fulcrum, thereby being opened / closed.

[0032]In the electric...

second exemplary embodiment

A Configuration Example of Electric Scissors

[0071]FIGS. 4 and 5 are side sectional views showing a configuration example of electric scissors according to a second exemplary embodiment; FIG. 4 shows a state in which the blades thereof are opened, and FIG. 5 shows a state in which the blades are closed. In FIGS. 4 and 5, mechanisms for driving one of the blades of the electric scissors are shown, and the housing, the operation section, etc. thereof are not shown.

[0072]Electric scissors 1B according to the second exemplary embodiment have a movable blade 2B and a fixed blade 3B, and the movable blade 2B is rotatably supported by a shaft 4B serving as a fulcrum.

[0073]In the electric scissors 1B, the rotation of a motor 5 is converted into a linear motion using a ball screw mechanism 6, and the drive power of the motor 5, the rotation of which is converted into a linear motion, is transmitted to the movable blade 2B using a toggle link mechanism 7B. As a result, the movable blade 2B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com