Guideway

a technology of guideway and longitudinal expansion, which is applied in the direction of electric vehicles, railway tracks, constructions, etc., can solve the problems of different deflection of adjacent guideway slabs, problems that can arise in the longitudinal expansion of carriers, etc., and achieve the effect of economic production of guideways and no obstacles to travel operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

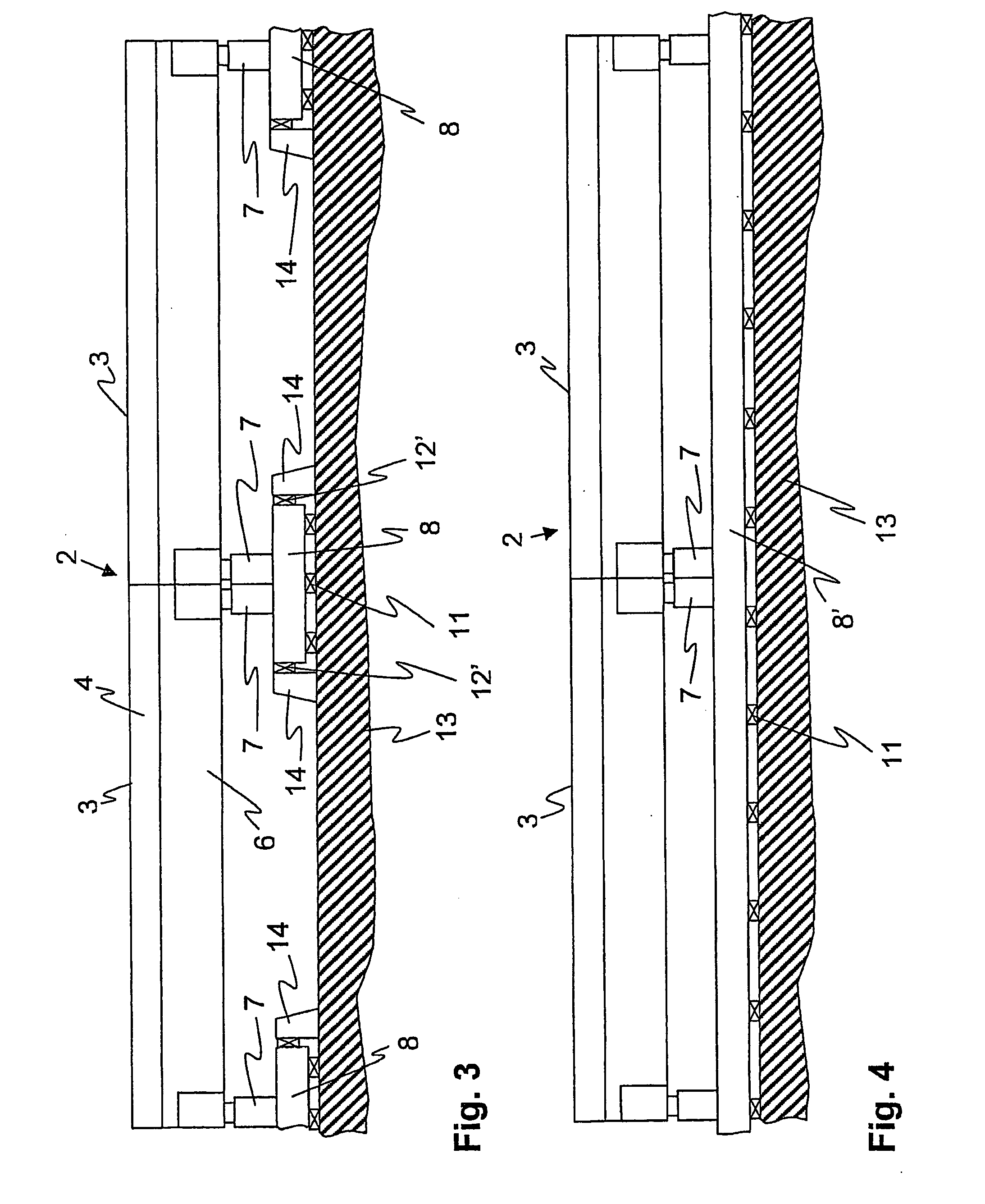

[0026]Reference will now be made to embodiments of the invention, one or more examples of which are illustrated in the drawings. Each embodiment is presented by way of explanation of the invention, and not as a limitation of the invention. For example, features illustrated or described as part of one embodiment may be used with another embodiment to yield still a further embodiment. It is intended that the invention include these and other modifications and variations of the embodiments described herein.

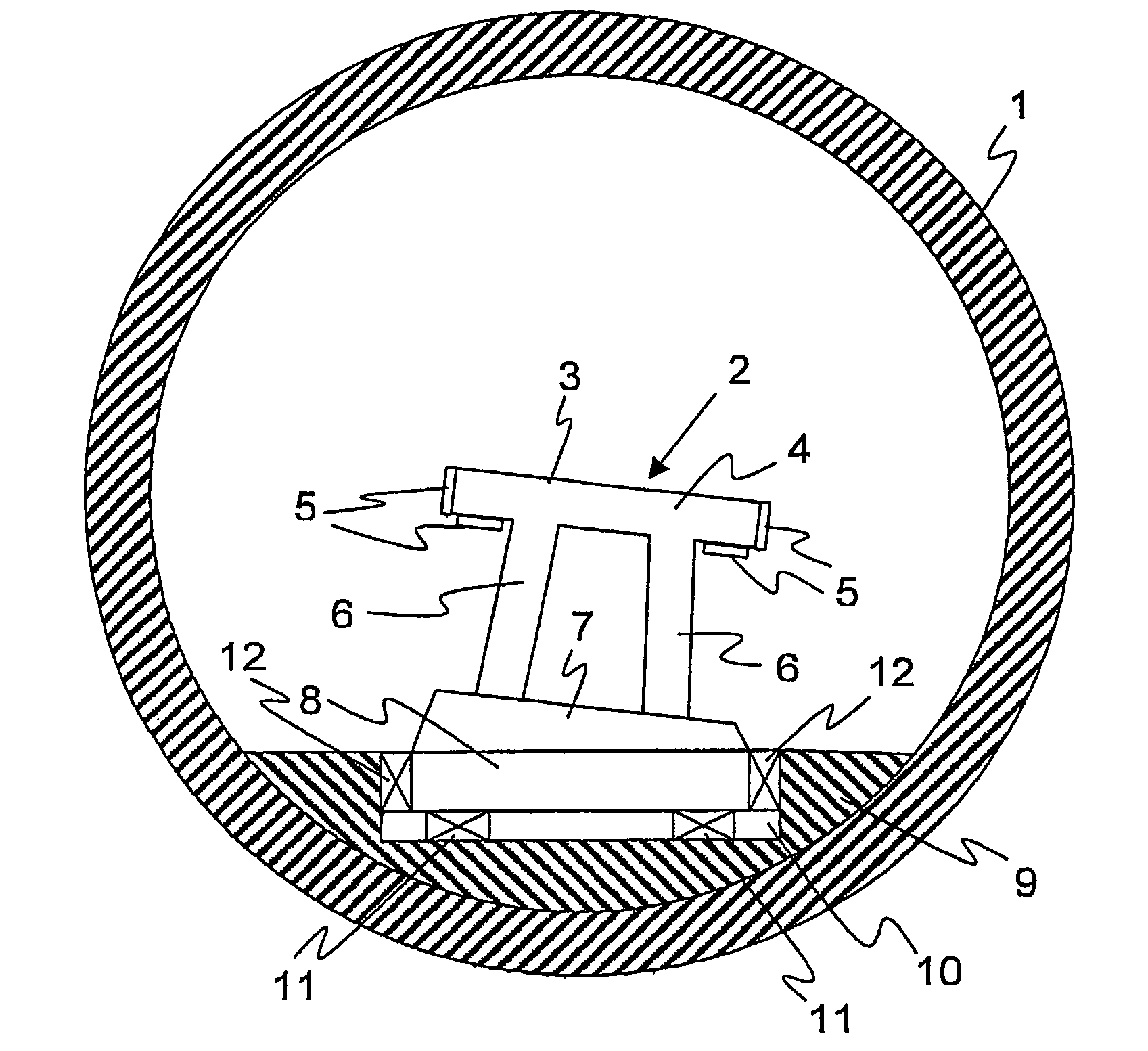

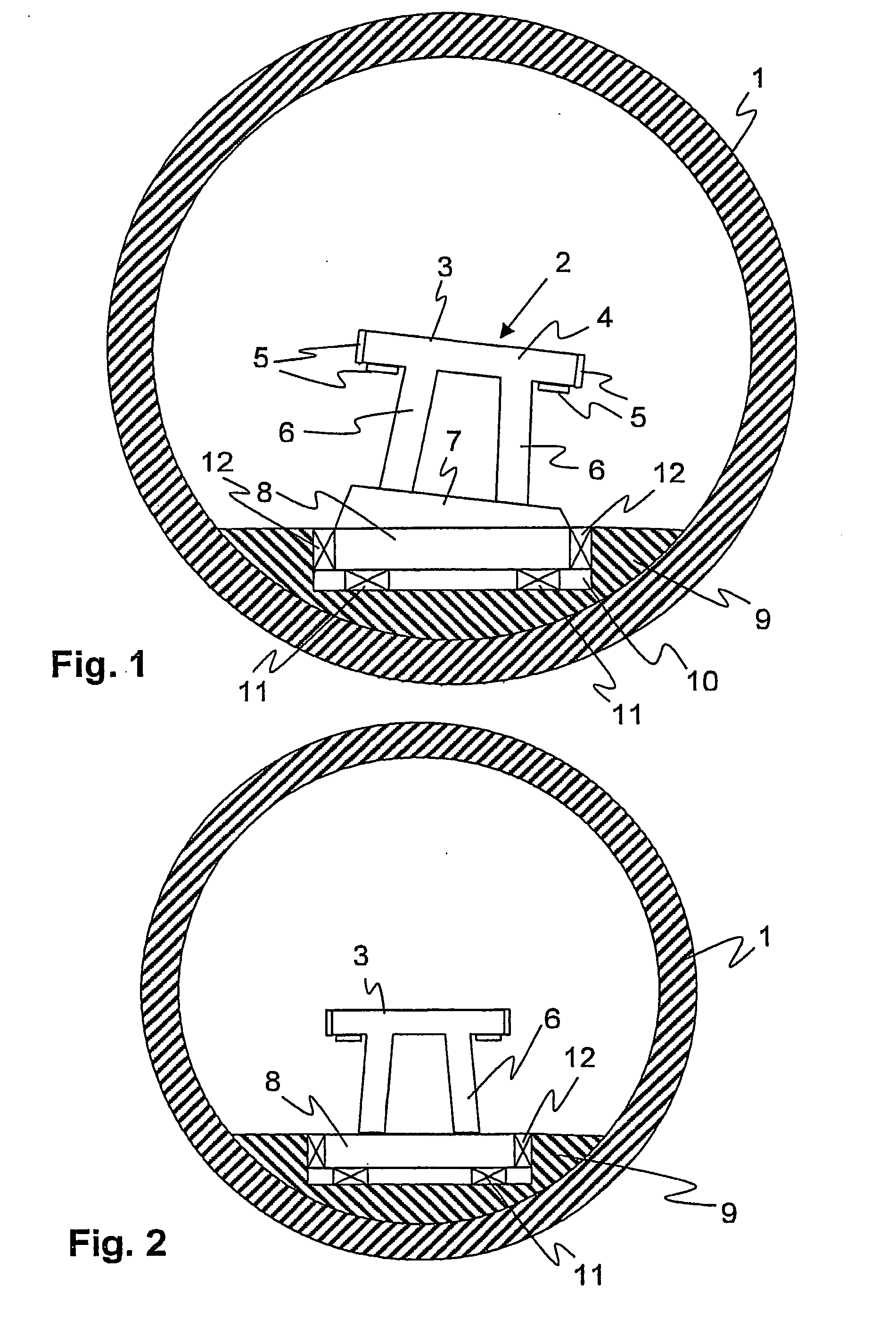

[0027]FIG. 1 shows a cross section through a tunnel 1 in which a guideway 2 with a carrier 3 is arranged. The guideway 2 is provided in the present exemplary embodiment for a vehicle of a magnetic suspension railway. However, it can also be provided, for example, for a railroad. The carrier 3 comprises a guideway slab 4 on whose lateral edges guidance elements 5 for the vehicle are fastened. The guidance elements 5 serve for the lateral guidance of the vehicle, as well as for its dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com