Modular necks for orthopaedic devices

a technology of orthopaedic devices and modules, applied in the field of orthopaedic implants, can solve the problems of increasing the risk of fracture, and increasing the risk of surgery,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

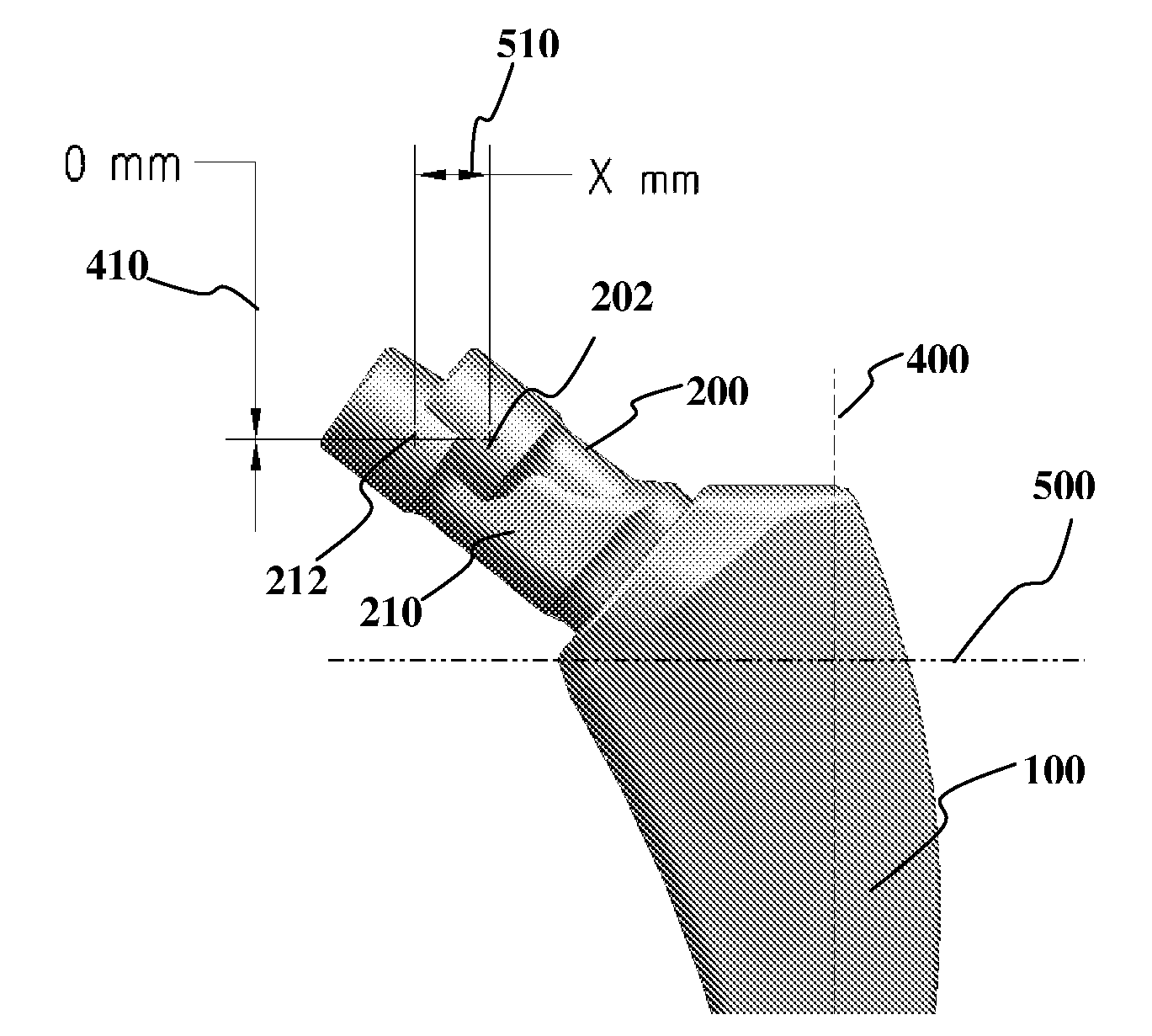

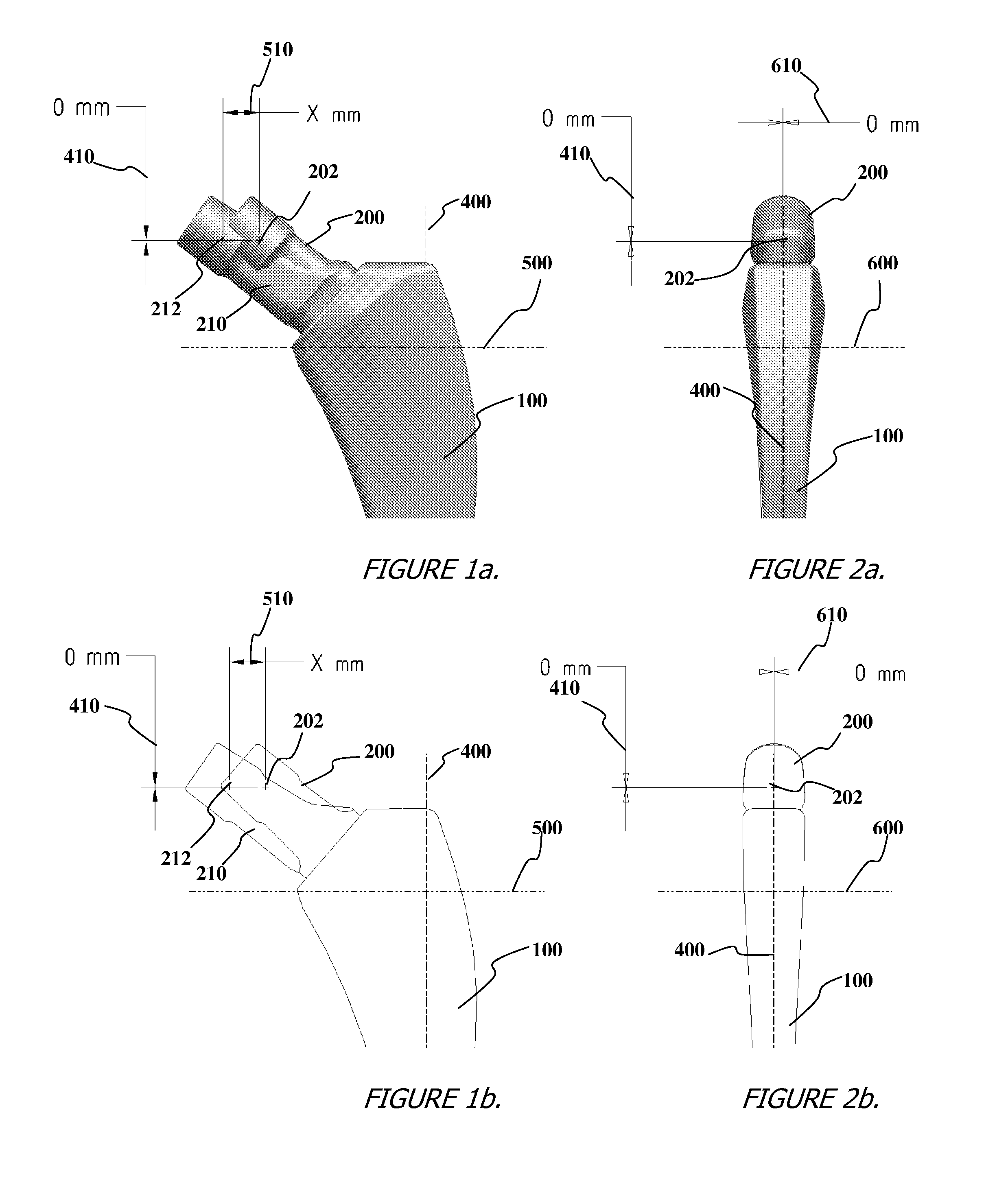

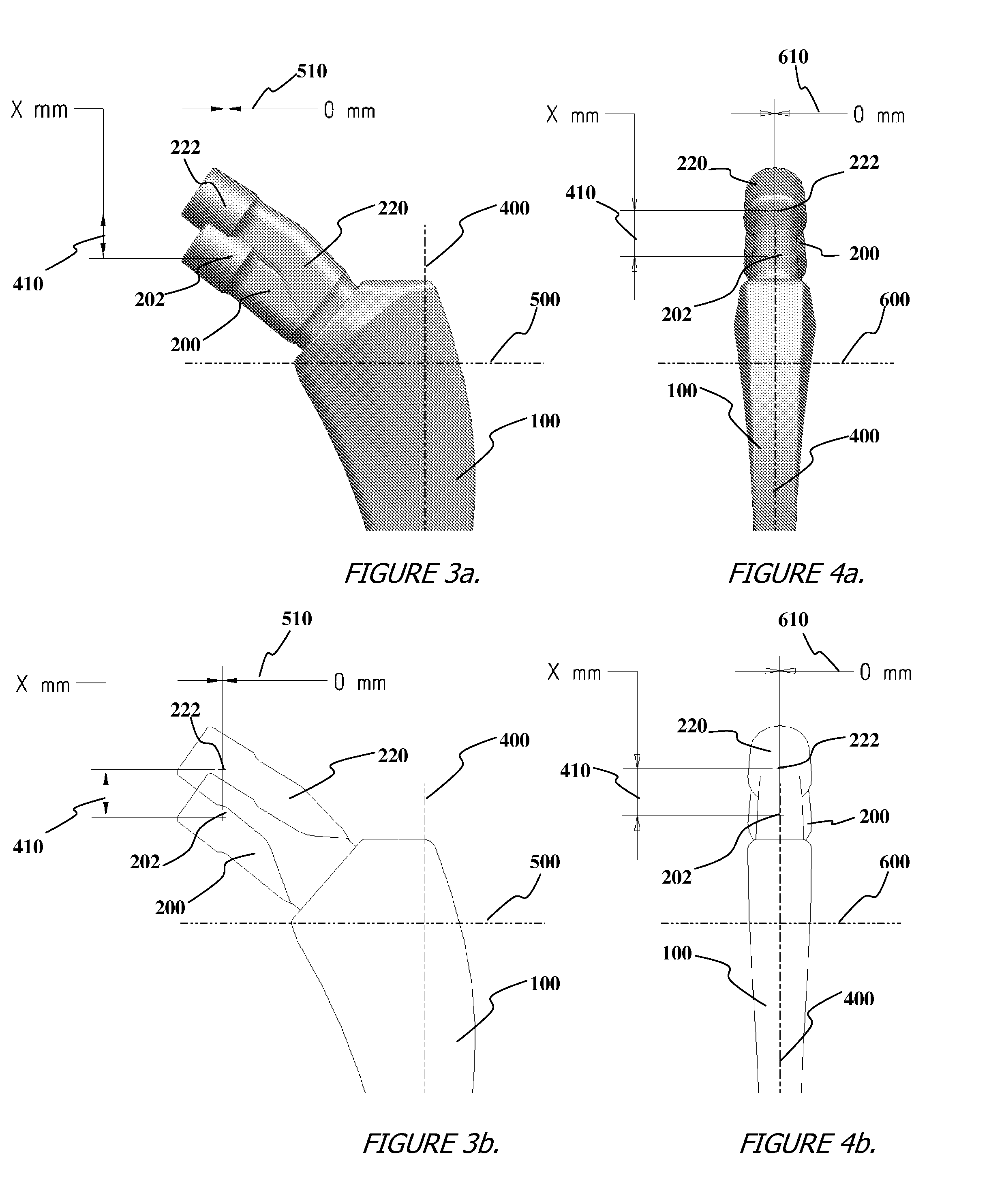

[0032]Referring to the accompanying drawings, FIGS. 1a-2b illustrate a system of modular orthopaedic devices according to some embodiments. The system comprises a femoral stem (100) and one of at least two neck segments (200, 210). The neck segments (200, 210) generally have a proximal end configured to receive a femoral head implant (not shown), and a distal end configured to be operably received by the femoral stem (100). The junction between the neck segments (200, 210) may be any known in the art, but is preferably a Morse taper lock. The proximal end of each neck comprises a central portion (202, 212) which is representative of the femoral head center when each of a femoral stem (100), neck (200), and femoral head implant (not shown) are assembled together.

[0033]One of said at least two neck segments may be a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com