Seal Structure and Control Method Therefor

a technology of sealing structure and sealing layer, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of frictional heat generated heat accumulated in the thermal insulation layer is transmitted to the rotating portion, and the rotor does not rotate smoothly, so as to improve the sealing performance, smooth start up the steam turbine, and suppress the effect of rotating portion temperature ris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Embodiments of the present invention will hereinafter be described in detail with reference to the drawings.

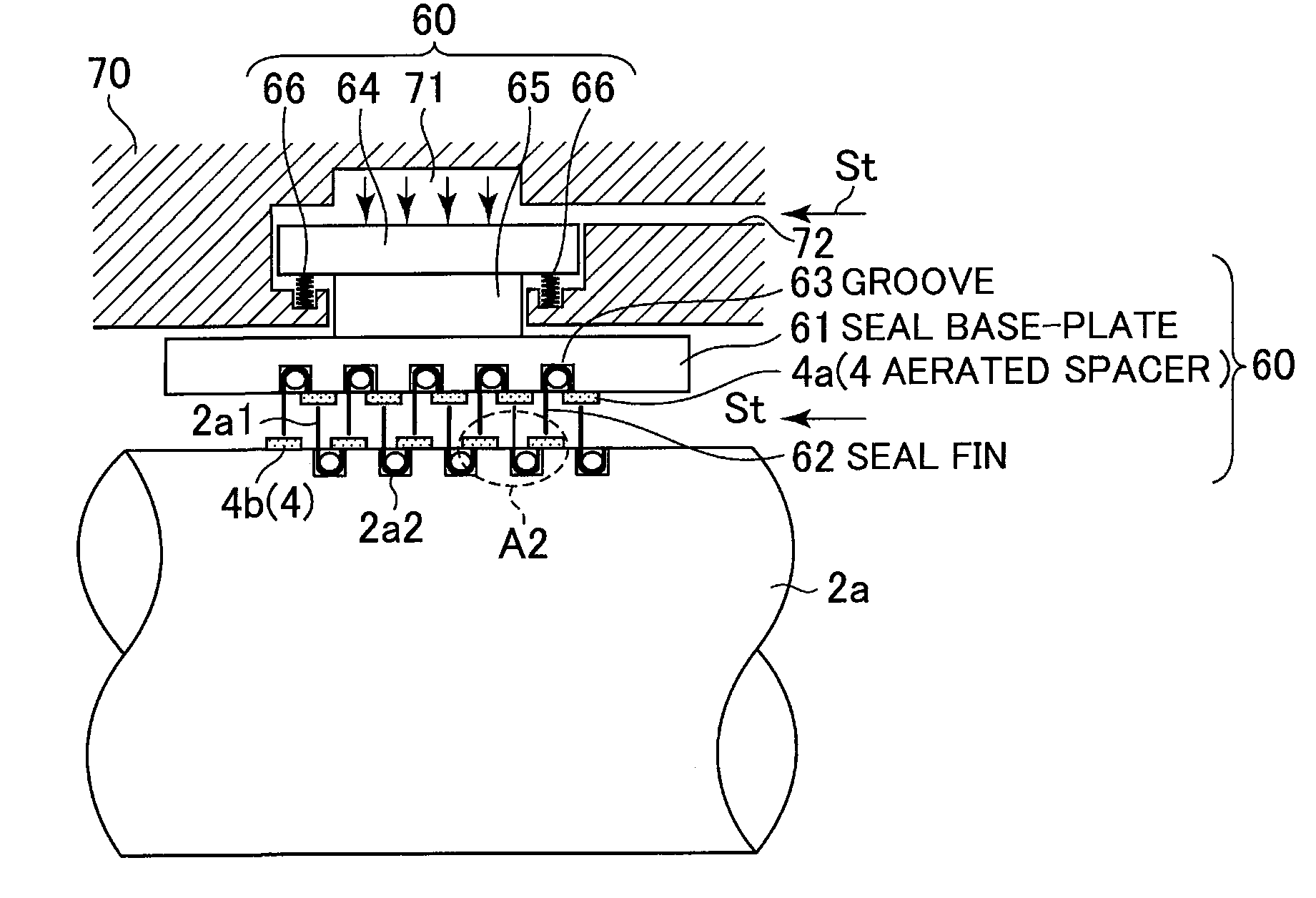

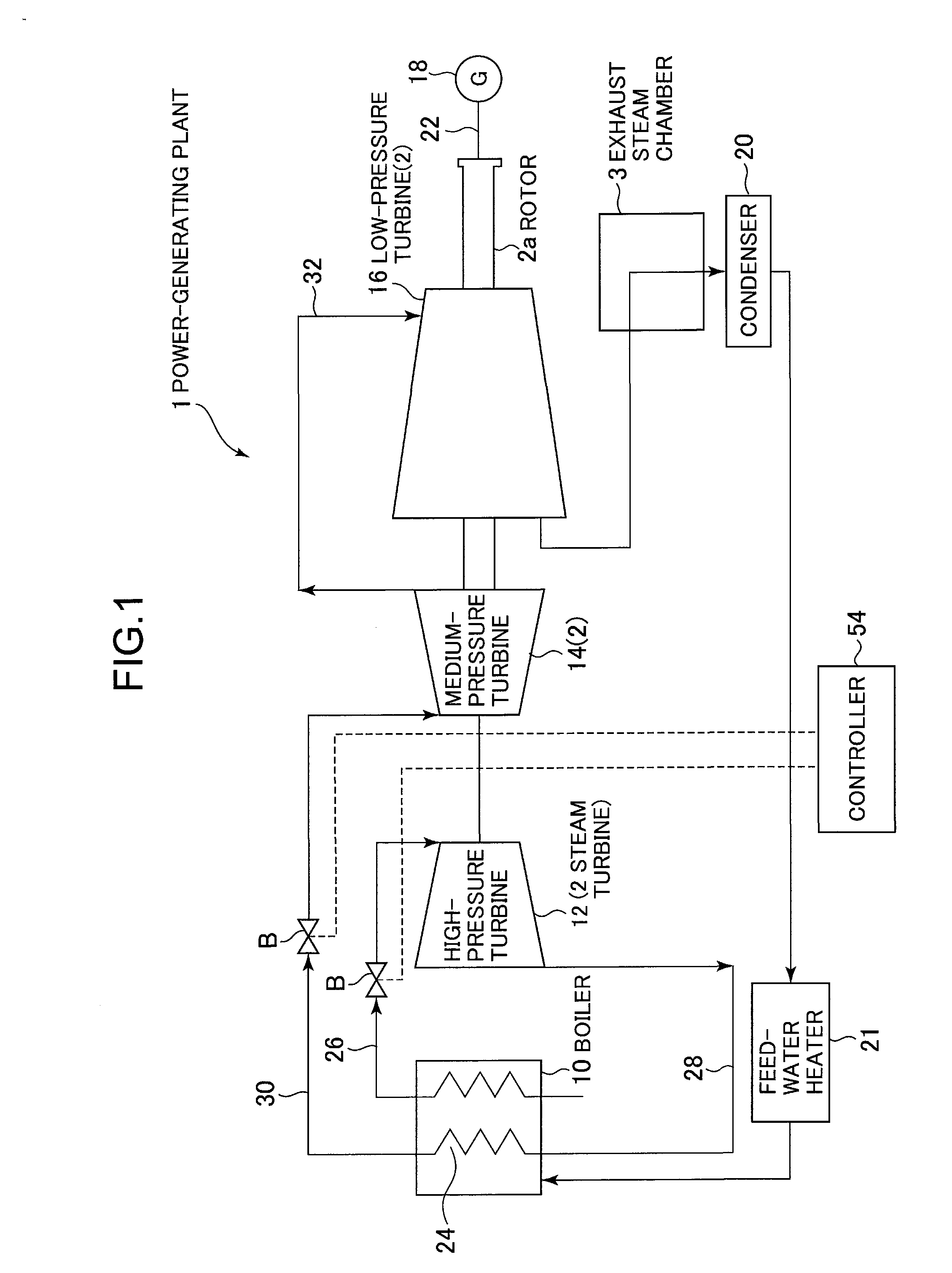

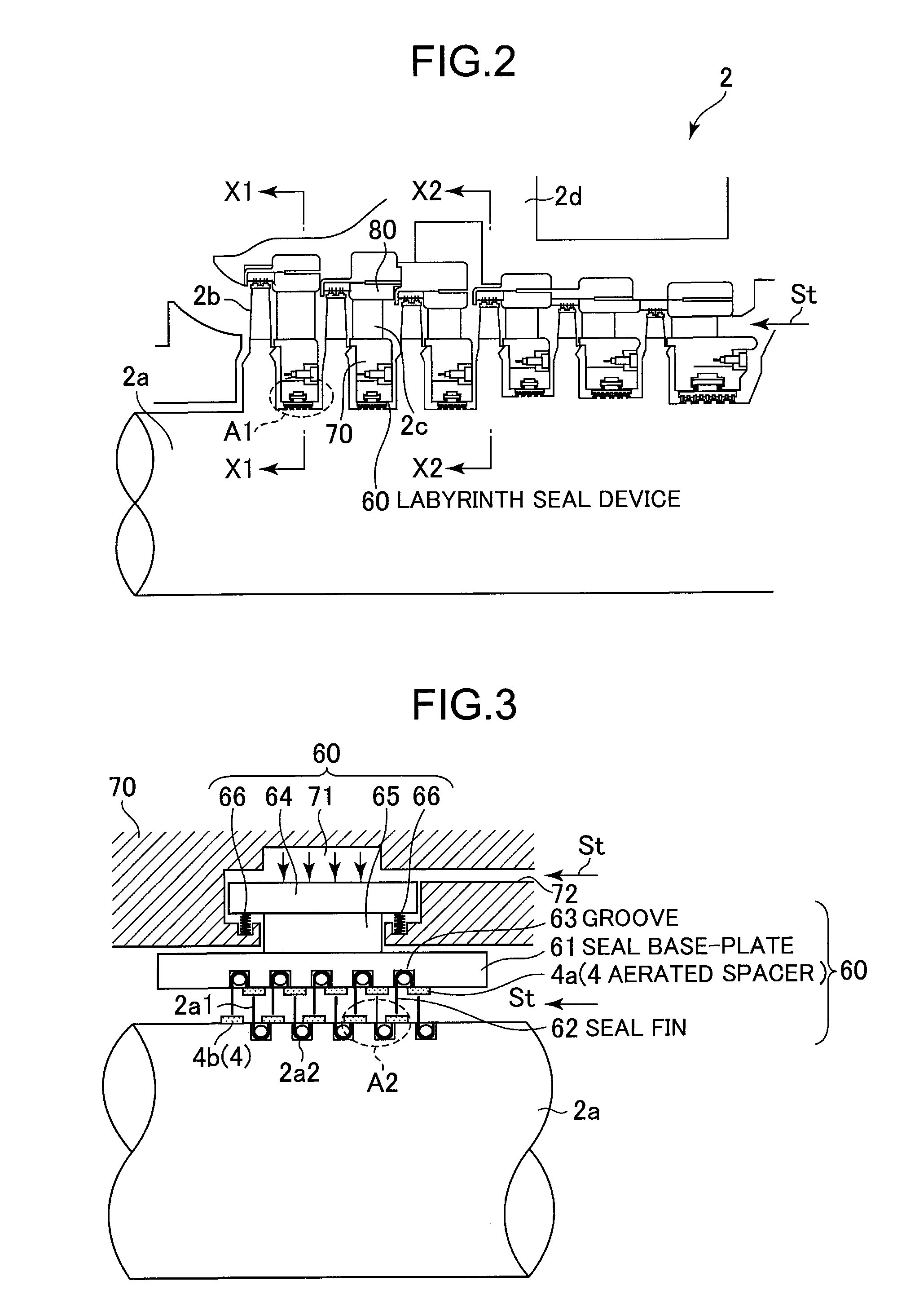

[0033]Referring to FIG. 1, a power-generating plant 1 is configured to include a boiler 10, a steam turbine 2 (a high-pressure turbine 12, a medium-pressure turbine 14, and a low-pressure turbine 16), a generator 18, and a condenser 20. A rotor 2a of the low-pressure turbine 16 is coupled to a drive shaft 22 of the generator 18. Rotation of the low-pressure turbine 16 drives the generator 18 for electric generation.

[0034]The boiler 10 is a steam generator, which is provided with a reheater 24. The boiler 10 is connected to an inlet side of the high-pressure turbine 12 via a pipe 26. An outlet side of the high-pressure turbine 12 is connected to the reheater 24 of the boiler 10 via a pipe 28. The reheater 24 is connected to an inlet side of the medium-pressure turbine 14 via a pipe 30. An outlet side of the medium-pressure turbine 14 is connected to an inlet side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com