Electrolytic hydrogen generating system

a hydrogen generating system and electrolysis technology, applied in the direction of electrochemical machining apparatus, metal-working apparatus, machines/engines, etc., can solve the problems of insufficient supply of gas at acceptable temperatures, unsatisfactory hydrogen generating system that efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

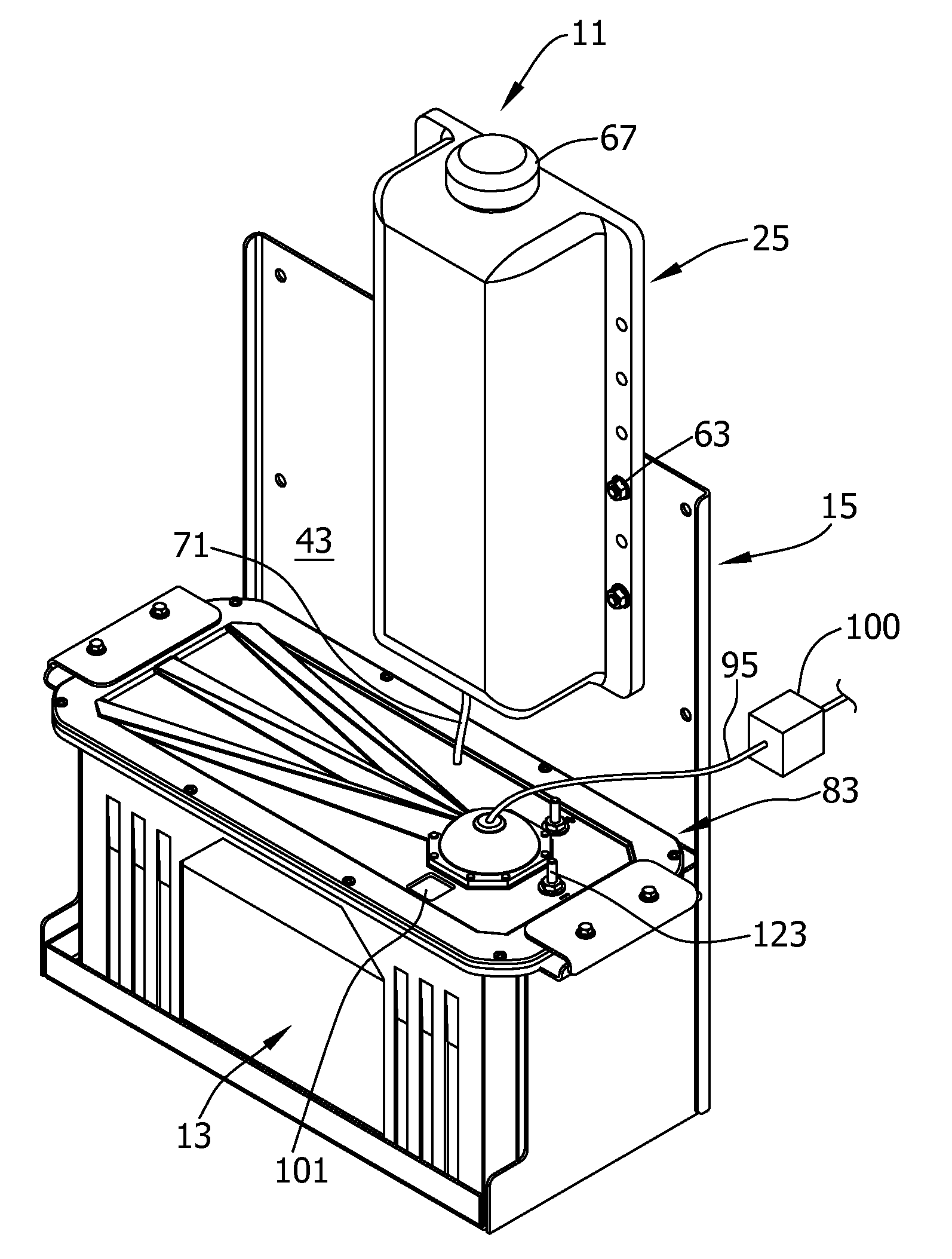

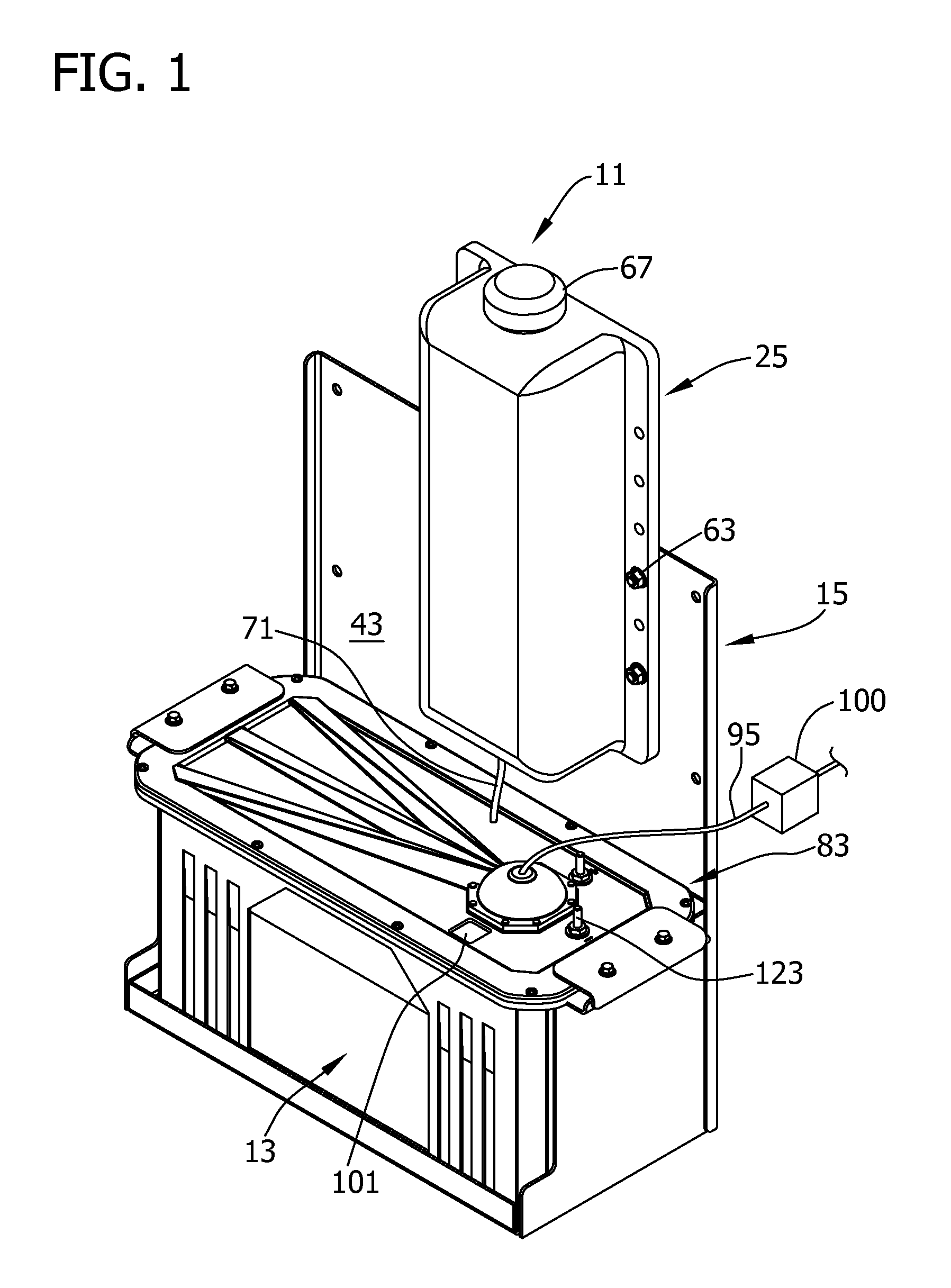

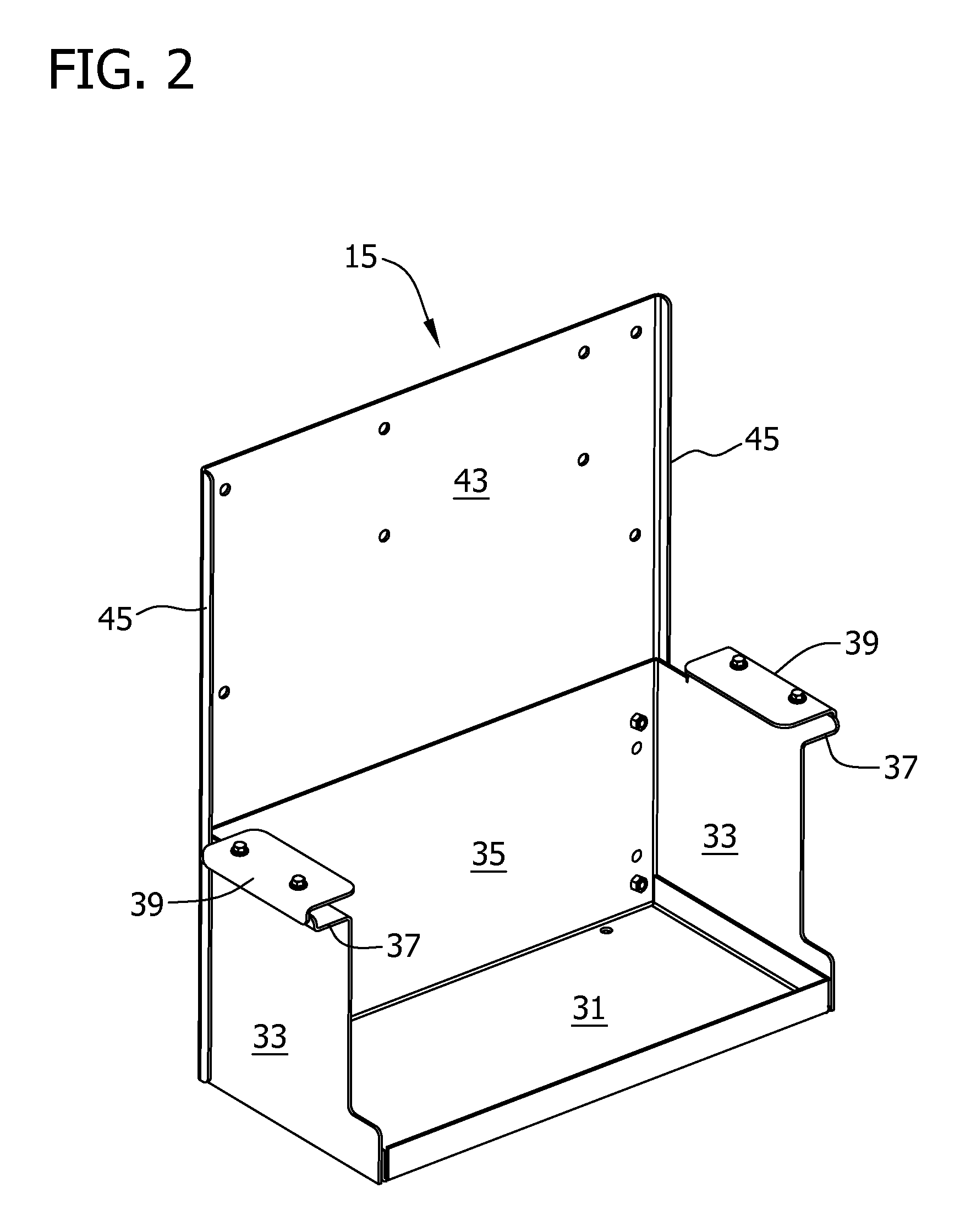

[0039]Referring now to the drawings and particularly to FIG. 1, a fuel emission device or hydrogen generating system of one suitable embodiment is generally designated 11. The hydrogen generating system 11 generally comprises a housing 13 and a frame 15 for supporting the housing 13. In this embodiment, the hydrogen generating system 11, and in particular the housing 13 and the frame 15, are adapted for mounting on a vehicle 19 (see FIG. 18), such as a diesel tractor of a tractor-trailer combination, and operably connected to an internal combustion engine 21 (see FIG. 18). A power source of the hydrogen generating system 11 may be, for example a 12 volt or a 24 volt source, though the hydrogen generating system 11 may be adapted to multiple voltage sources. This embodiment also includes a reservoir 25 containing maintenance solution 27, as shown in FIG. 5, for facilitating continued operation of the hydrogen generating system 11. The reservoir 25 may, however, be omitted within the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com