Drive device for erosion tools

a technology of drive device and tool, which is applied in the direction of manufacturing tools, electrical circuits, electrical-based machining electrodes, etc., can solve the problems of adding materially to manufacturing costs, and achieve the effects of high precision, good rinsing of the bore gap, and high quality of bore formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

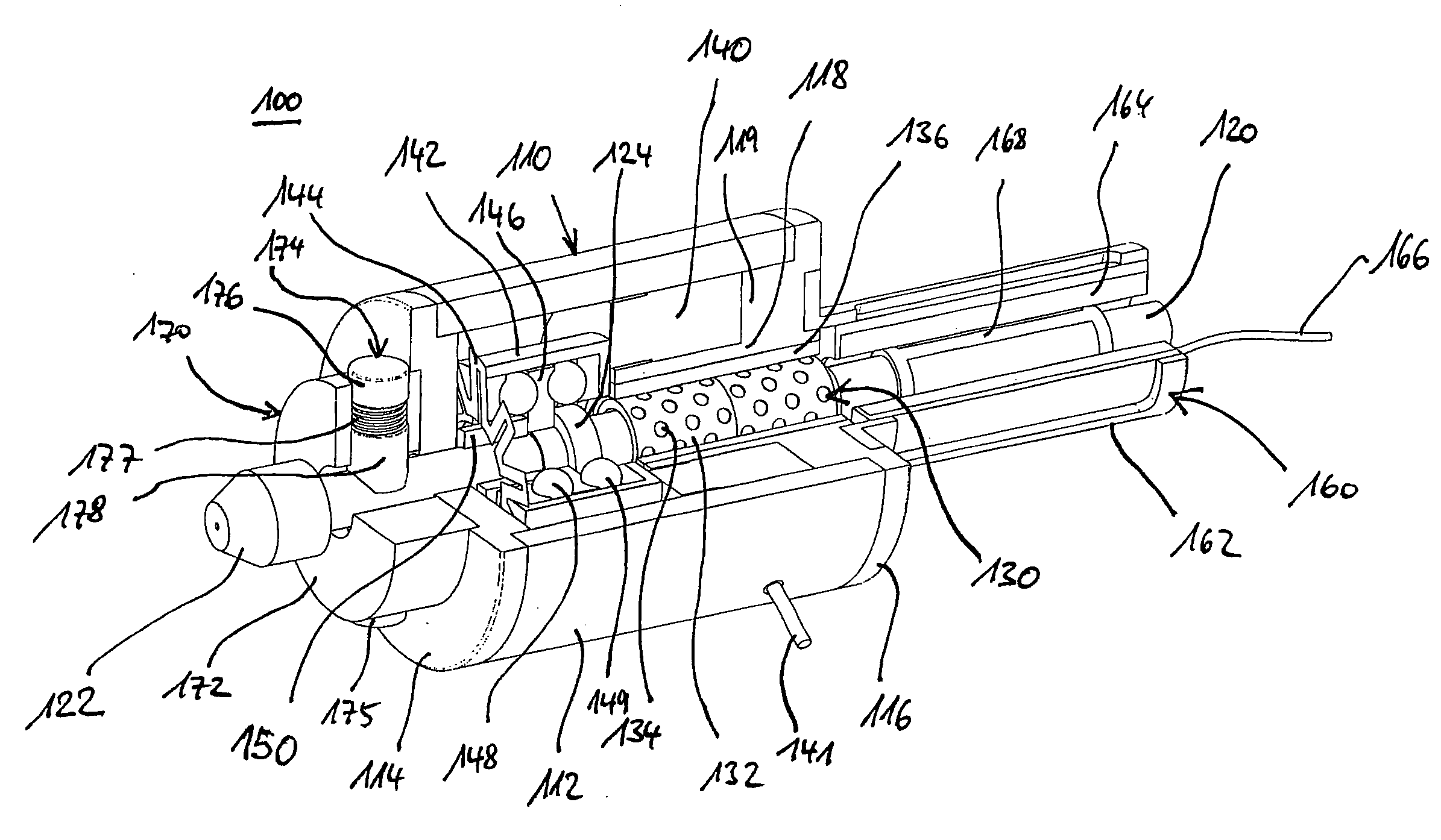

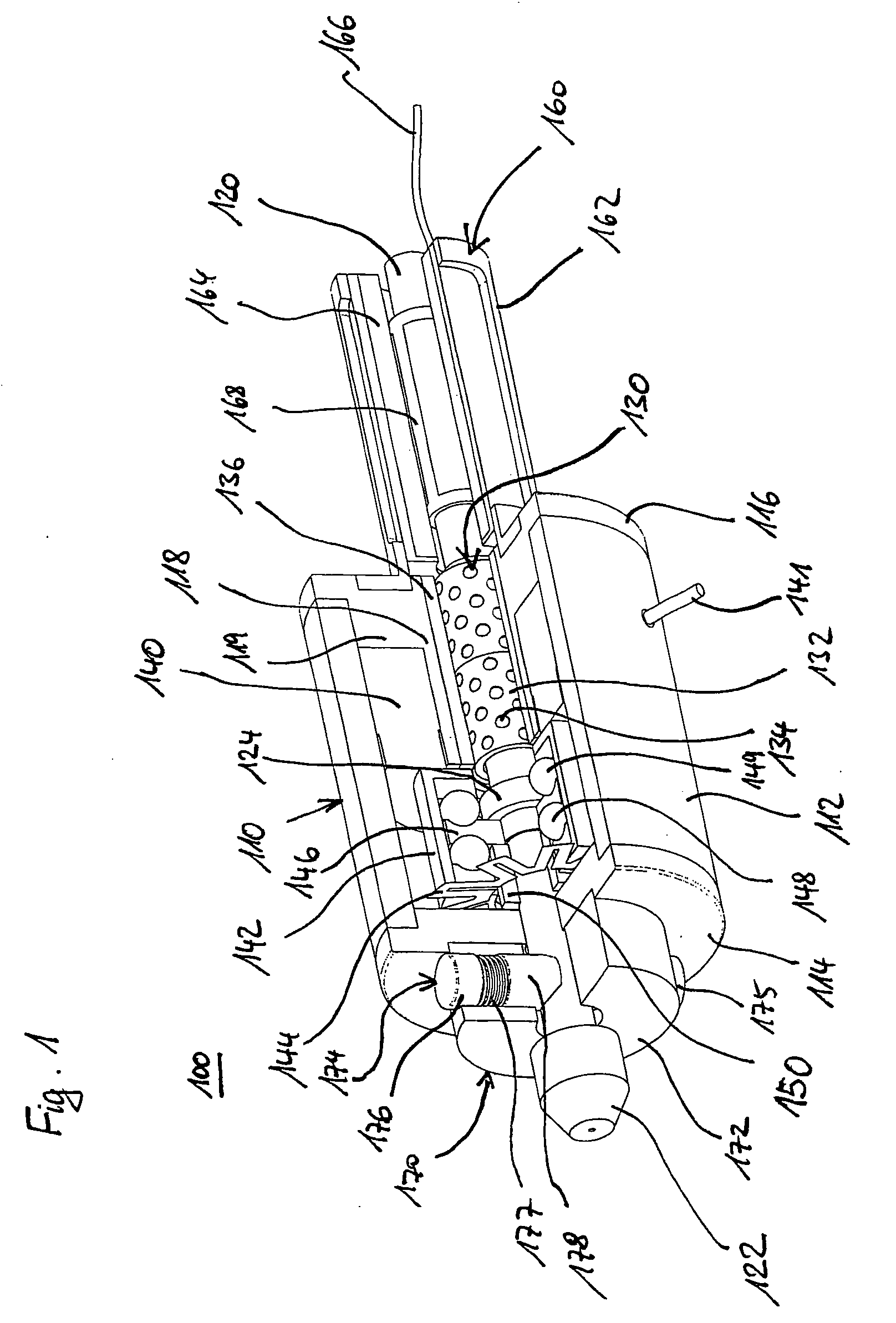

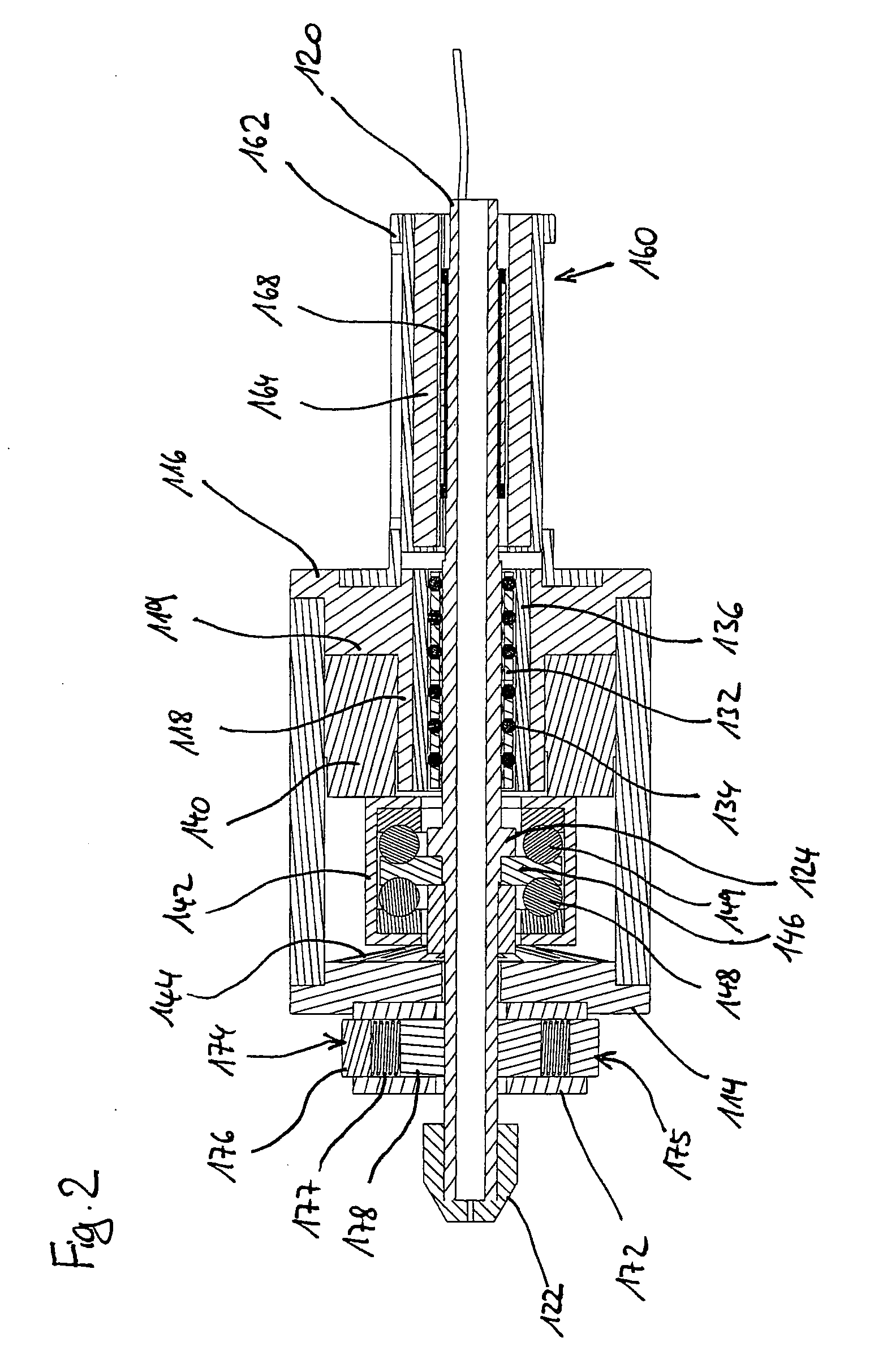

[0050]The drive device 100 illustrated in FIGS. 1 and 2 has a housing 110 with a cylindrical housing shell 112 and two housing covers (114, 116) at respective ends of the housing. A drive shaft 120 is coaxially mounted in the housing 110; shaft 120 exits the housing 110 through the end-disposed housing covers (114, 116). The drive shaft has on one end an electrode accommodating or holding structure 122 in which the eroding electrode (not shown) can be held by compressive force.

[0051]At approximately the axial middle of the shaft, the shaft is radially supported by a ball track 130. The ball track 130 is comprised of a ball race 132 in which a plurality of rows of balls 134 are disposed which rows are distributed around the circumference, said balls being constrained from departing from the race but being allowed to move e.g. rotate relatively freely. The ball race is preferably comprised of plastic so that the balls are retained frictionlessly in the race. The ball track 130 further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal diameter | aaaaa | aaaaa |

| vibration frequency | aaaaa | aaaaa |

| vibration frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com